Polymer composition for 3D printing, material, method and molded article thereof

A 3D printing and polymer technology, applied in the direction of solid material additive processing, 3D object support structure, additive processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0070] Take polymer SEBS 6014 (styrene content 18 wt%) 20 wt% and processing aid Oil150N 80 wt% as the polymer composition. The polymer composition is kneaded and granulated by twin-screw extruder at 160-230° C. to obtain kneaded particles. The kneaded particles were shot into flat test pieces and their hardness was measured. After the kneaded particles were left to stabilize for 1 day, the MFI value was measured. Then the FDM particle feed printing feasibility analysis (140°C) was performed.

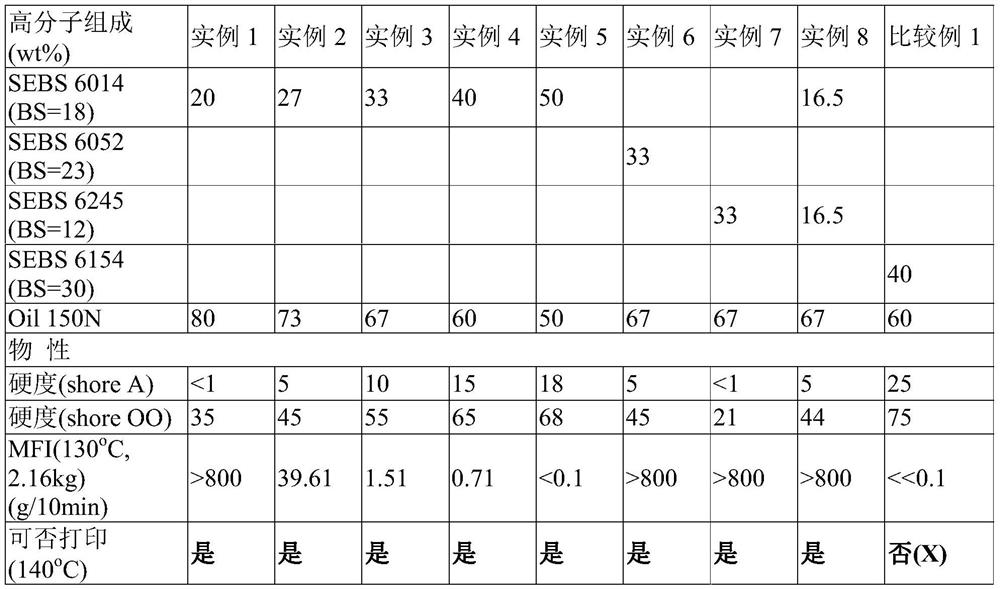

[0071] The polymer compositions of Examples 1 to 8 and Comparative Example 1 are all SEBS and Oil 150N. The polymer compositions of these examples can be referred to Table 1. The practice of these examples can refer to Example 1.

[0072] Table 1

[0073]

[0074] The meanings of the symbols in the tables of the present invention are explained below. X: It means that it cannot be printed, that is, the material cannot be extruded from the printing nozzle smoothly, so the materia...

example 9

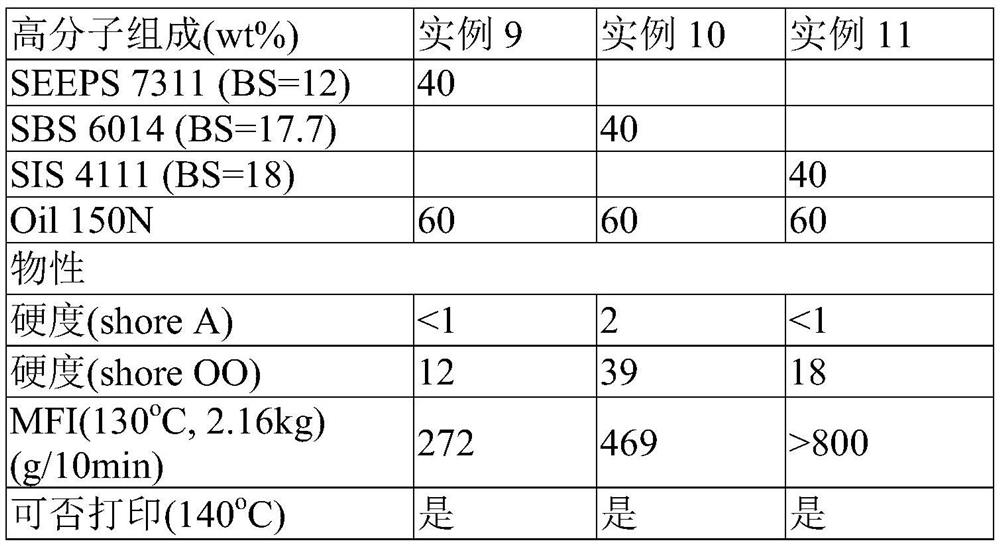

[0076] The macromolecule composition of Examples 9 to 11 is composed of one of the macromolecules selected from SEEPS, SBS, and SIS, and the processing aid Oil 150N is added. The practice of these examples can refer to Example 1. The polymer compositions of these examples can be referred to Table 2.

[0077] Table 2

[0078]

[0079] Referring to Table 2, Examples 9 to 11 show the successfully printed polymer composition, the styrene content of SEEPS / SBS / SIS is less than 25% by weight. Table 2 also shows that in the polymer compositions of Examples 9 to 11, the weight ratio of SEEPS / SBS / SIS to Oil 150N is in the range of 1:1 to 1:4. In the present invention, there are other comparative examples (not shown in the table) in which the weight of the processing aid is greater than four times the weight of the vinyl aromatic block copolymer (SEEPS / SBS / SIS). The amount of oil that SEEPS / SBS / SIS can absorb is limited, so it cannot be processed and mixed. In Examples 9 to 11 tha...

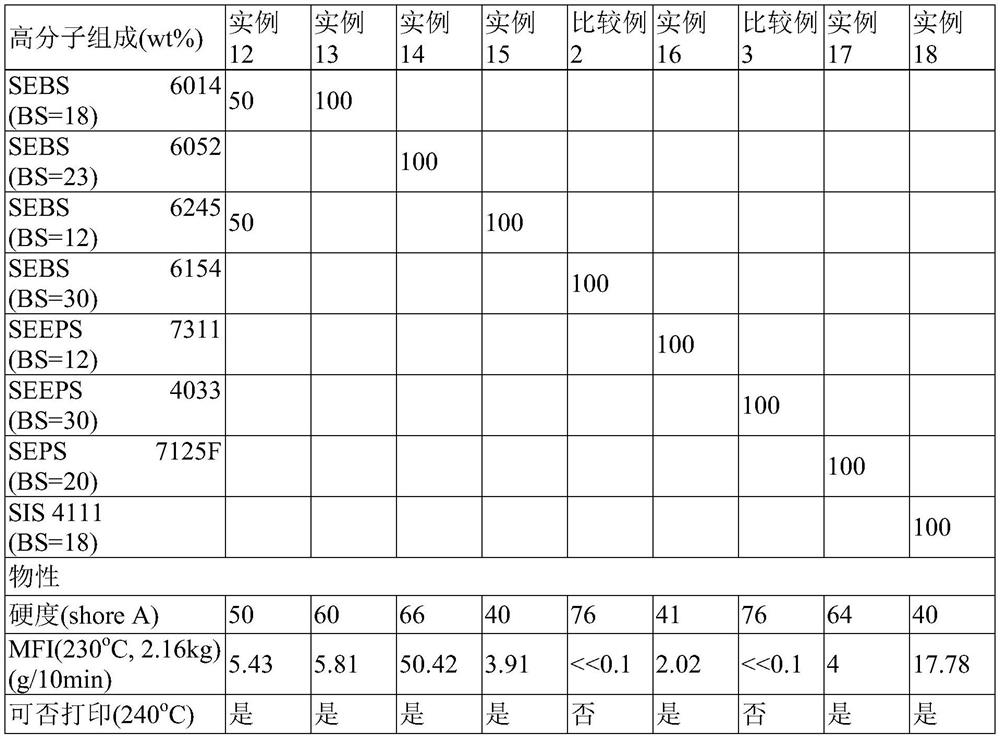

example 12

[0081] Take 50% by weight of polymer SEBS 6014 (18 wt% styrene content) and 50 wt% SEBS 6245 (12 wt% styrene content) as the polymer composition. The polymer composition is kneaded and granulated by twin-screw extruder at 160-230° C. to obtain kneaded particles. The kneaded particles were shot into flat test pieces and their hardness was measured. After the kneaded particles were left to stabilize for 1 day, the MFI value was measured. Then the FDM particle feed printing feasibility analysis (240°C) was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com