High-strength and thin-gauge steel plate/strip with fire resistance and weather resistance and a production method thereof

A fire-resistant, weather-resistant, and thin-gauge technology, applied in the field of continuous casting, can solve problems affecting surface quality, uneven cooling, and sheet shape deterioration, so as to improve the surface quality of strip steel, reduce the thickness of scale, and improve temperature uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention is described further below with embodiment and accompanying drawing, but these embodiments are in no way restricting the present invention. Any changes made by those skilled in the art in the implementation of the present invention under the inspiration of this specification will fall within the protection scope of the claims of the present invention.

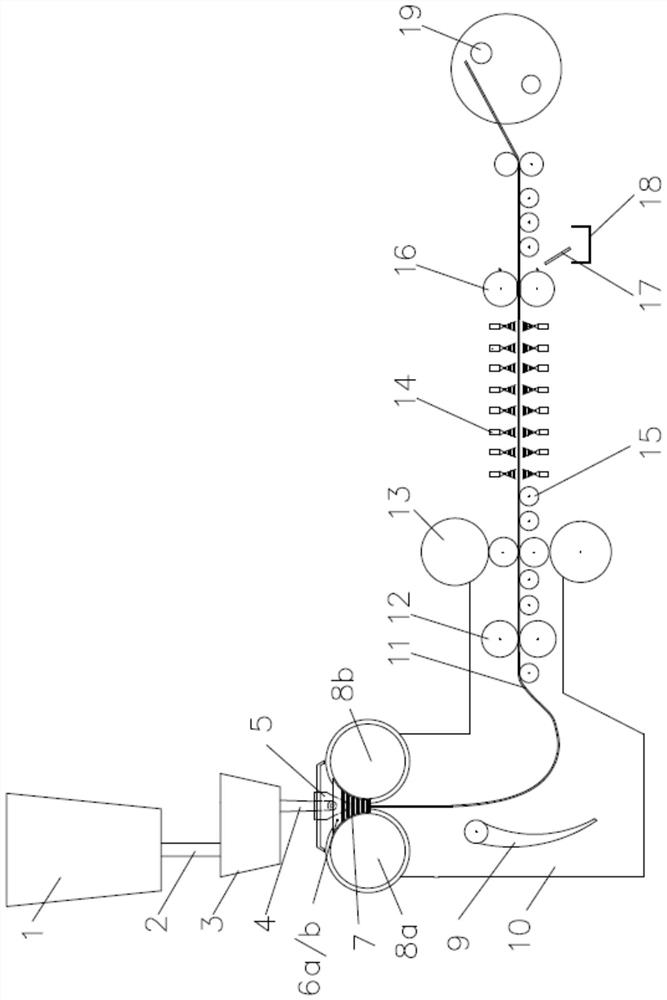

[0108] see figure 1, the molten steel conforming to the design of the chemical composition of the present invention is poured directly through the ladle 1, through the ladle long nozzle 2, the tundish 3, the submerged nozzle 4 and the flow distributor 5 in a crystallization chamber that is made of two relatively rotating and capable of rapid cooling. In the molten pool 7 surrounded by the rollers 8a, 8b and the side sealing plate devices 6a, 6b, the molten steel solidifies on the circumferential surface where the crystallization rollers 8a, 8b rotate, and then forms a solidified shell and gradually ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com