Support capable of supporting wall formwork on single side

A wall and formwork technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection, reduction of greenhouse gases, etc. Hidden dangers, inability to place tie bolts, etc., to achieve the effect of improving appearance quality, good economic benefits, and improving the quality of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

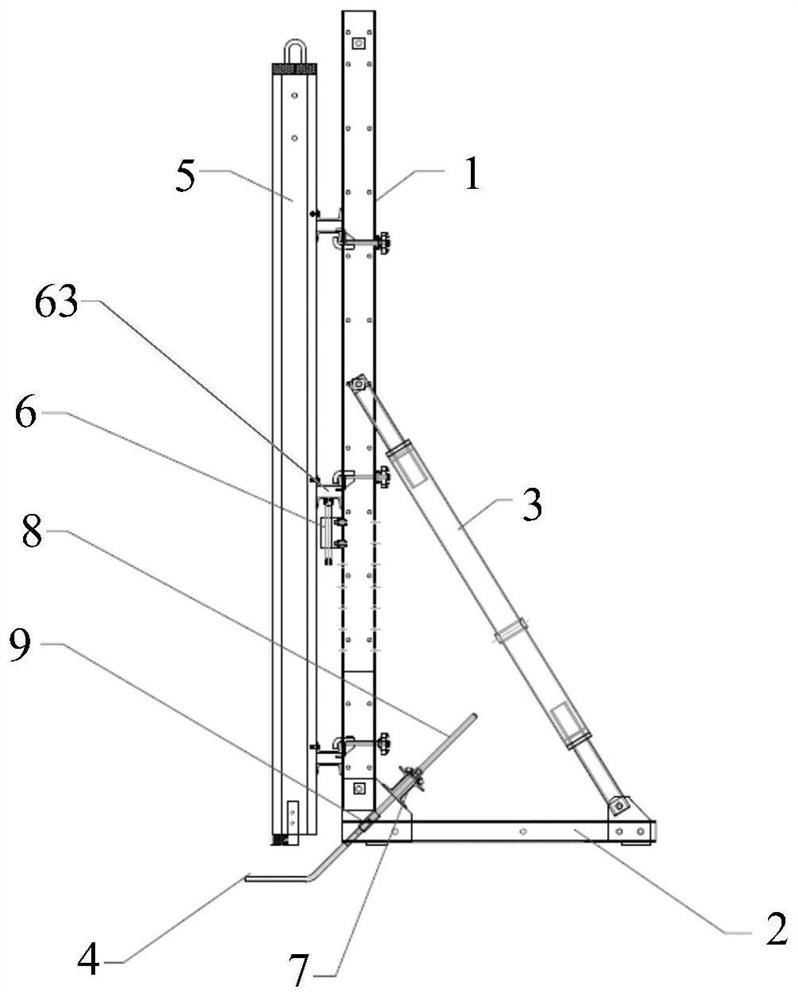

[0033] This embodiment provides a bracket that can support the wall formwork on one side, including the vertical main back flute 1, the ground beam 2, the diagonal brace 3 and the anchor bolt 4; the vertical main back flute 1, the ground beam 2 and the The diagonal braces 3 are connected in turn to form a right-angled triangle bracket. One end of the ground beam 2 is connected to one end of the vertical main back 1, and the axes of the two are perpendicular; one end of the diagonal brace 3 is connected to the other end of the ground beam 2, and the other end of the diagonal brace 3 One end is connected with the vertical bar section of the vertical main back flute 1. The ground beam 2 is used as a right-angled side for contact with the ground; the vertical main back flute 1 is used as another right-angled side for contact with the wall shaping formwork; the anchor bolts 4 pass through the ground beam 2 at the right angle of the triangular bracket Finally, it is used to be burie...

Embodiment 2

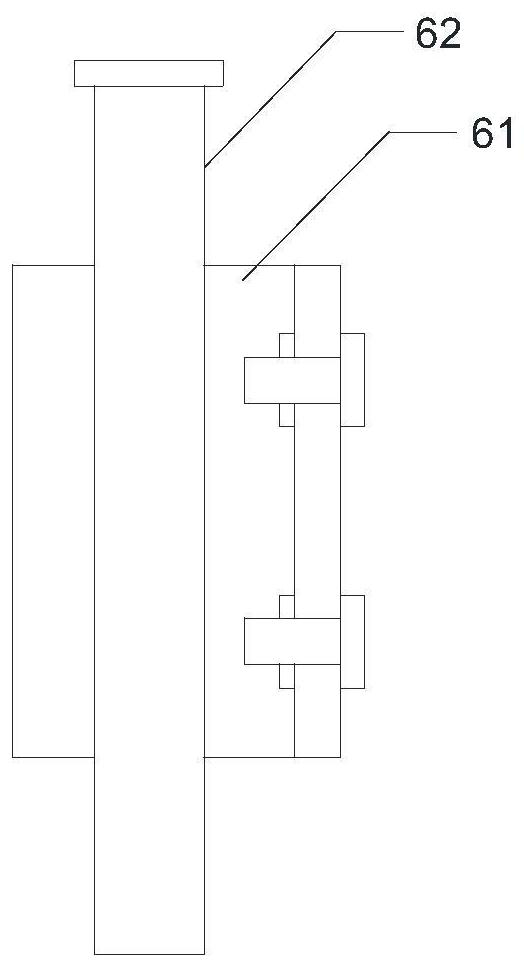

[0035] Further improvement on the basis of Example 1, the two optimized structures of the telescopic components are as follows:

[0036] The first type: the telescopic assembly adopts a hydraulic cylinder, an air cylinder or an electric push rod assembly, and this embodiment adopts a hydraulic cylinder. The fixed end of the telescopic assembly is hingedly connected to the ground beam 2 through a pin shaft, and the telescopic end of the telescopic assembly is hingedly connected to the vertical main back rib 1 through a pin shaft.

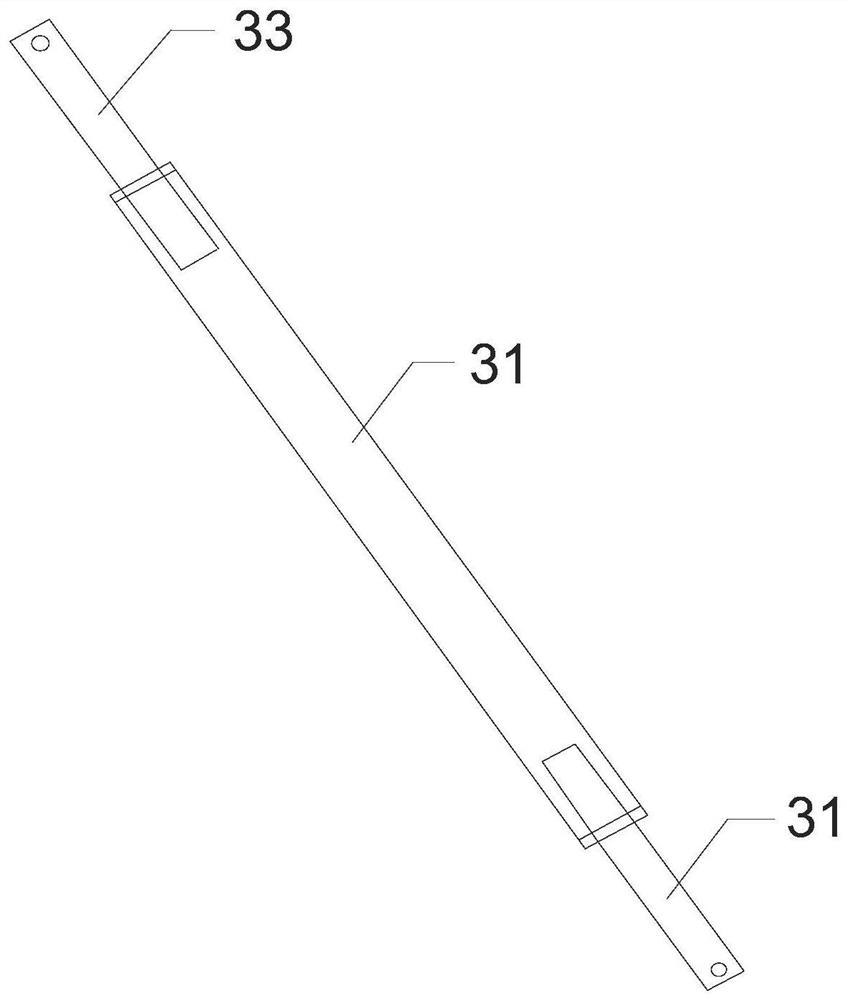

[0037] The second type: the telescopic assembly includes an adjustment cylinder 31, an adjustment screw I32 and an adjustment screw II33; the adjustment cylinder 31 is provided with an internal thread; The threaded connection extends into the adjustment cylinder 31; one end of the adjustment bolt II33 is hingedly connected with the vertical main back corrugated 1, and the other end is threaded into the adjustment cylinder 31 by the other end of the a...

Embodiment 3

[0041] Further improvement on the basis of embodiment 2 includes a plurality of right-angled triangular brackets, and the plurality of right-angled triangular brackets are sequentially arranged along the width extension direction of the wall shaped formwork. Adjacent right-angled triangles are connected by steel pipes, and the axial ends of each steel pipe are respectively fixedly connected to the vertical main back flute 1 on the corresponding side.

[0042] Also includes a pressure beam 7, the pressure beam 7 is extended and arranged along the arrangement direction of all right-angled triangular brackets, a number of through holes are opened on the pressure beam 7, and all the through holes are distributed sequentially along the axial extension direction of the pressure beam 7; through the outer connecting rod 8 is connected with the anchor bolt 4 after passing through the through hole, and is tightened and fixed by the lock nut; Contact with ground beam 2. The vertical mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com