Method for exploiting common thickened oil by utilizing high-permeability strip

A high-permeability strip and ordinary technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of expanding the sweeping range of the near wellbore area, the difficulty of effective plugging, and the channeling of injected fluid , to achieve wide reservoir adaptability, low ground equipment requirements, and improved gas-oil mobility ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

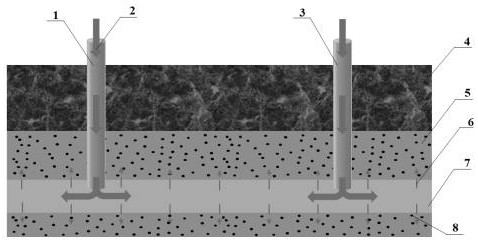

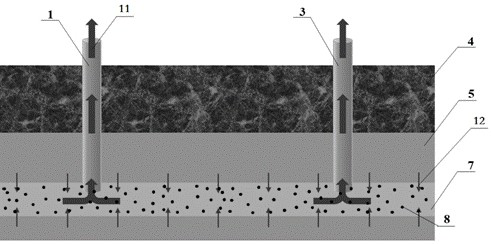

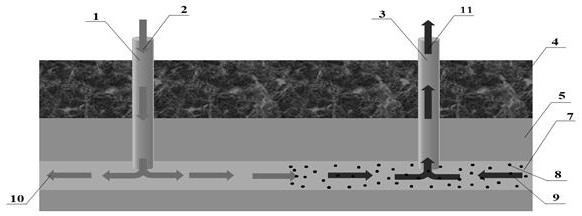

[0029] For ordinary heavy oil reservoirs in the middle and later stages of water flooding production, water channeling channels have been formed, and they are in the high water-cut production stage. The method for using high-permeability strips to exploit ordinary heavy oil is adopted, and the specific steps are as follows:

[0030] (1) Select the oil reservoirs for development: According to the reservoir characteristics and development status of the reservoirs, the applicable oil reservoirs are roughly screened according to the following conditions, and at least the following conditions are met: the oil reservoirs are ordinary oil with a viscosity of 200mPa·s Heavy oil reservoir; the average thickness of the oil-bearing reservoir is 5 m; the oil-bearing area is about 0.3km 2 ;The horizontal permeability is about 200×10 -3 µm 2 ;The reservoir has been exploited by water flooding, channeling has formed in the reservoir, and high-permeability strips are developed, with a water ...

Embodiment 2

[0039] For ordinary heavy oil reservoirs exploited by foam flooding, the method for exploiting ordinary heavy oil using high-permeability strips is adopted, and the specific steps are as follows:

[0040] (1) Select the oil reservoir for development: According to the characteristics of the reservoir and the current development status, roughly screen the applicable oil reservoir according to the following conditions, and at least meet the following conditions: the oil reservoir is an ordinary oil reservoir with a crude oil viscosity of 500mPa·s Heavy oil reservoir; the average thickness of the oil-bearing reservoir is 6m; the oil-bearing area is about 0.5km 2 ; The horizontal permeability is about 400×10 -3 µm 2 ; The reservoir has been exploited by foam flooding, channeling has formed in the reservoir, and high-permeability strips are developed;

[0041] (2) Huff and puff production stage: a. Inject gas or a compound system of gas and chemical agent: inject gas or a compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com