Natural gas hydrate separation equipment and process

A technology for separating equipment and natural gas, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of small processing capacity, poor adaptability, easy formation of air resistance, etc., and achieve good operating flexibility and convenient sand discharge , Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

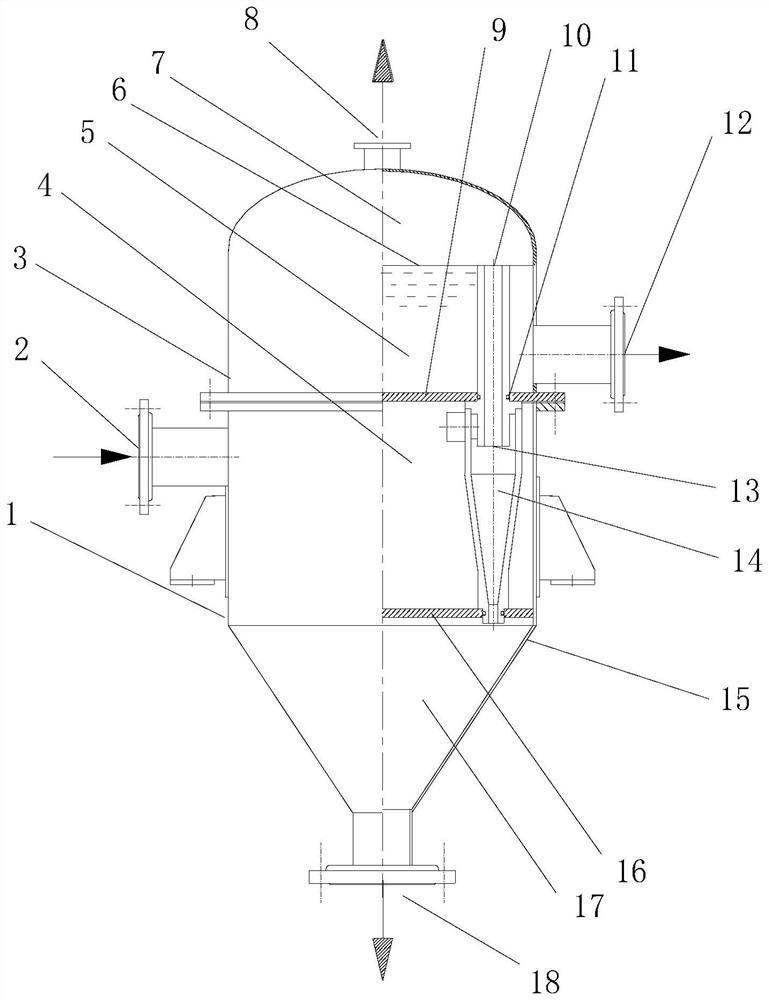

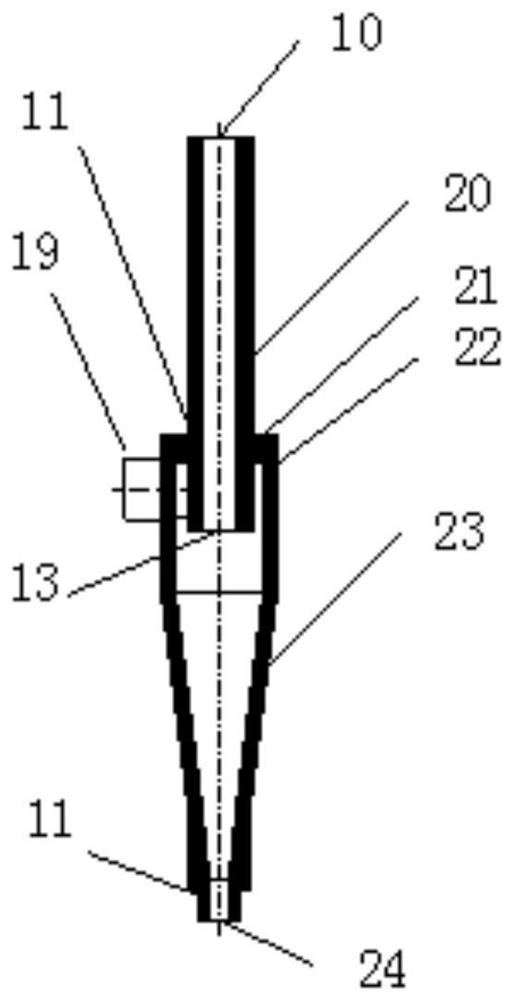

[0028] In order to express the structural advantages of this natural gas hydrate separation device more clearly, the following combination Figure 1-2 Further explain the functional characteristics of this device.

[0029] Such as figure 1 with figure 2 As shown, the natural gas hydrate separation equipment includes an upper cylinder body 3, a lower cylinder body 1, and one or more parallel cyclone separation pipes 14 arranged inside the joint space of the upper cylinder body 3 and the lower cylinder body 1, and the joint space The interior is divided into three chambers from top to bottom by the upper partition 9 and the lower partition 16, namely the overflow chamber, the feeding chamber 4 and the sand collection chamber 17. The upper and lower cylinders are connected by flanges to form a mating space. The upper partition 9 is welded to the lower end of the upper cylinder 3 . The lower partition 16 is welded on the cylinder inner wall of the lower cylinder 1 . An overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com