High-pressure gas flow rapid pressure reduction fairing device and method

A technology of rectification device and gas flow, which is applied in the direction of jet propulsion device, rocket engine device, machine/engine, etc., and can solve the requirement that the space occupied by the rectification device is not harsh, the pressure is high, and it cannot meet the rapid decompression of engine gas, Rectification and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

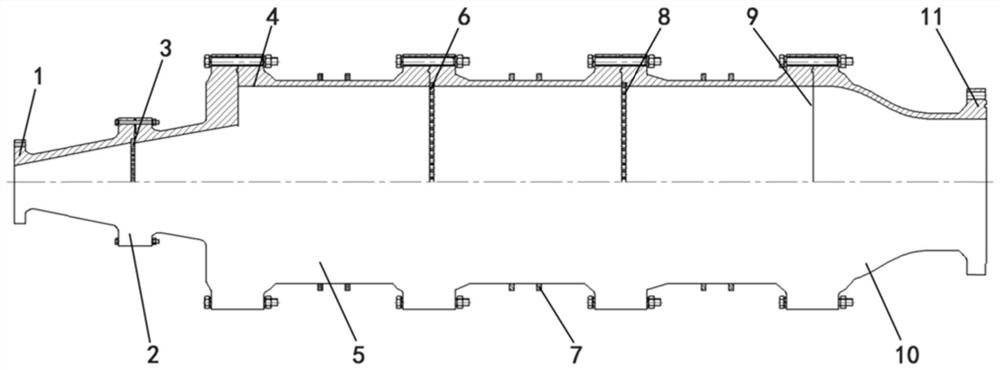

[0044] The decompression and rectification device has been successfully applied in the semi-system test run of a conventional afterburning engine, the theoretical temperature of the upstream gas is 750K, and the total pressure is 24MPa.

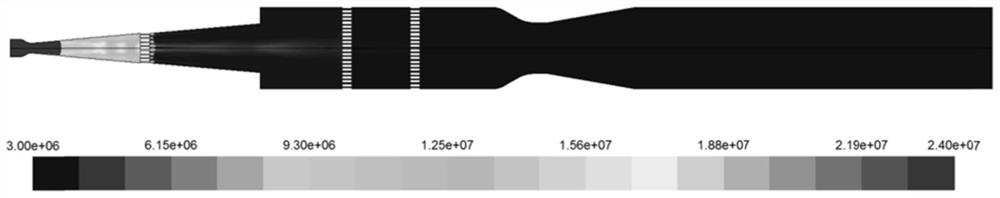

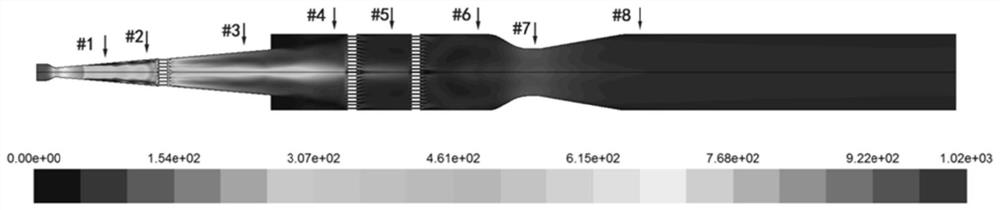

[0045] figure 2 is the pressure change of the flow field in the decompression rectification device under the above conditions. Depend on figure 2 It can be seen that the gas flow forms a primary shock wave in the front part of the supersonic shock wave section 2, the total gas pressure before the shock wave is 24MPa, and the total gas pressure after the shock wave is 14MPa; behind the porous damping plate 3, a secondary shock wave is generated, and the gas flow The total pressure dropped for the second time. The total gas pressure before the porous damping plate 3 was 14MPa, and after the porous damping plate 3, the total pressure of the gas dropped to 3-4MPa; the total pressure of the gas flow at the outlet flange 11 dropped to 3MPa.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com