Infrared food detector

A detector and food technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems affecting the smooth flow of the production line, interfering with the normal operation of the assembly line, and affecting the food production efficiency, so as to enhance the inspection efficiency, avoid relative slippage, and maintain operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

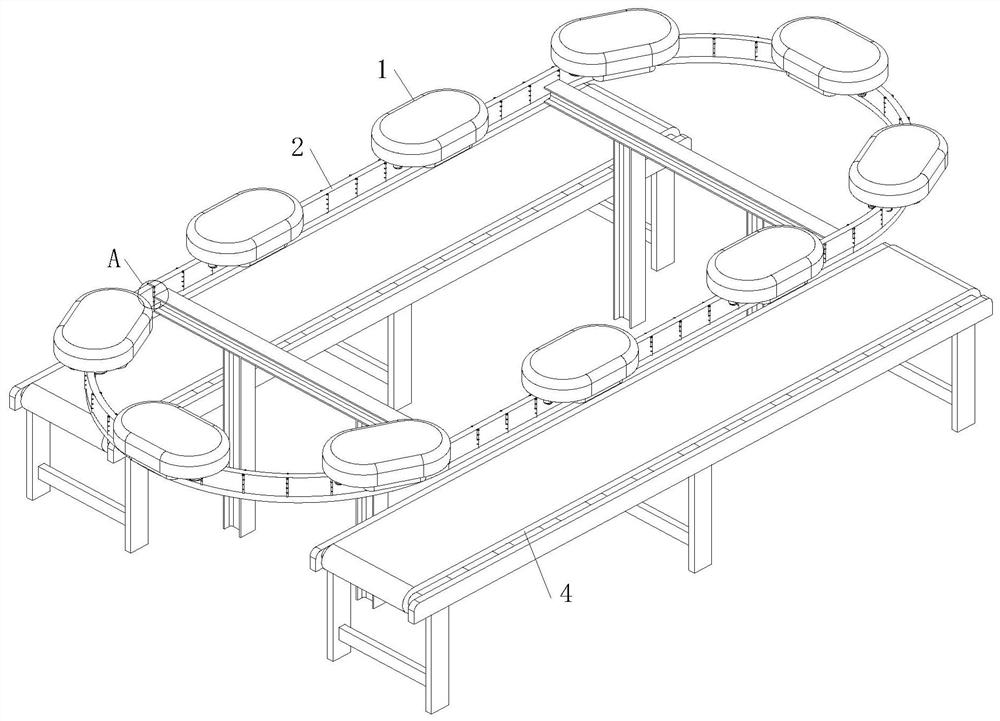

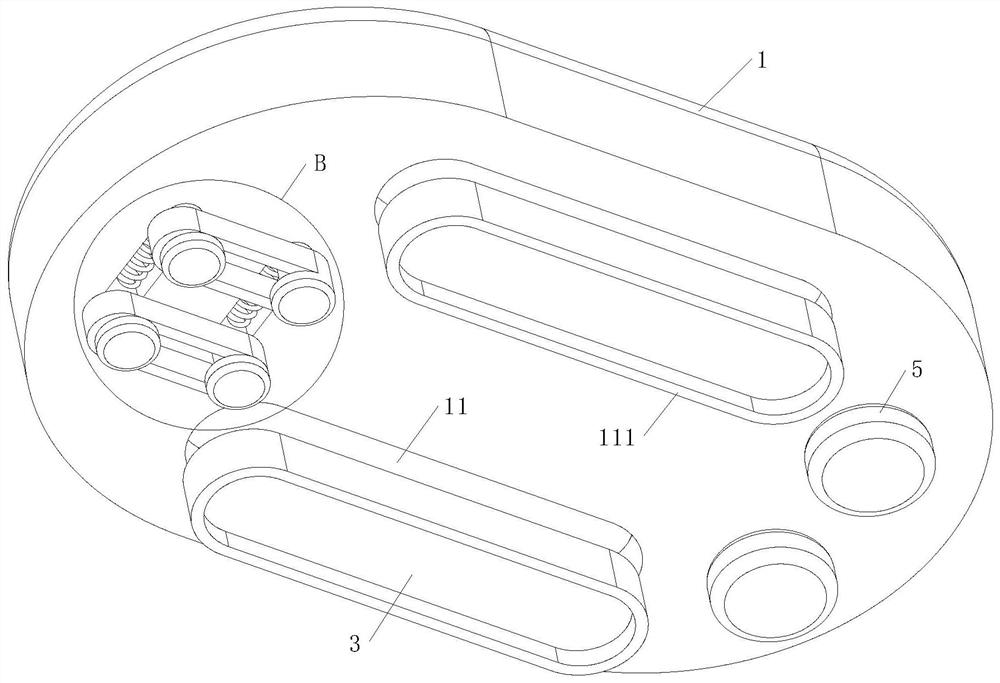

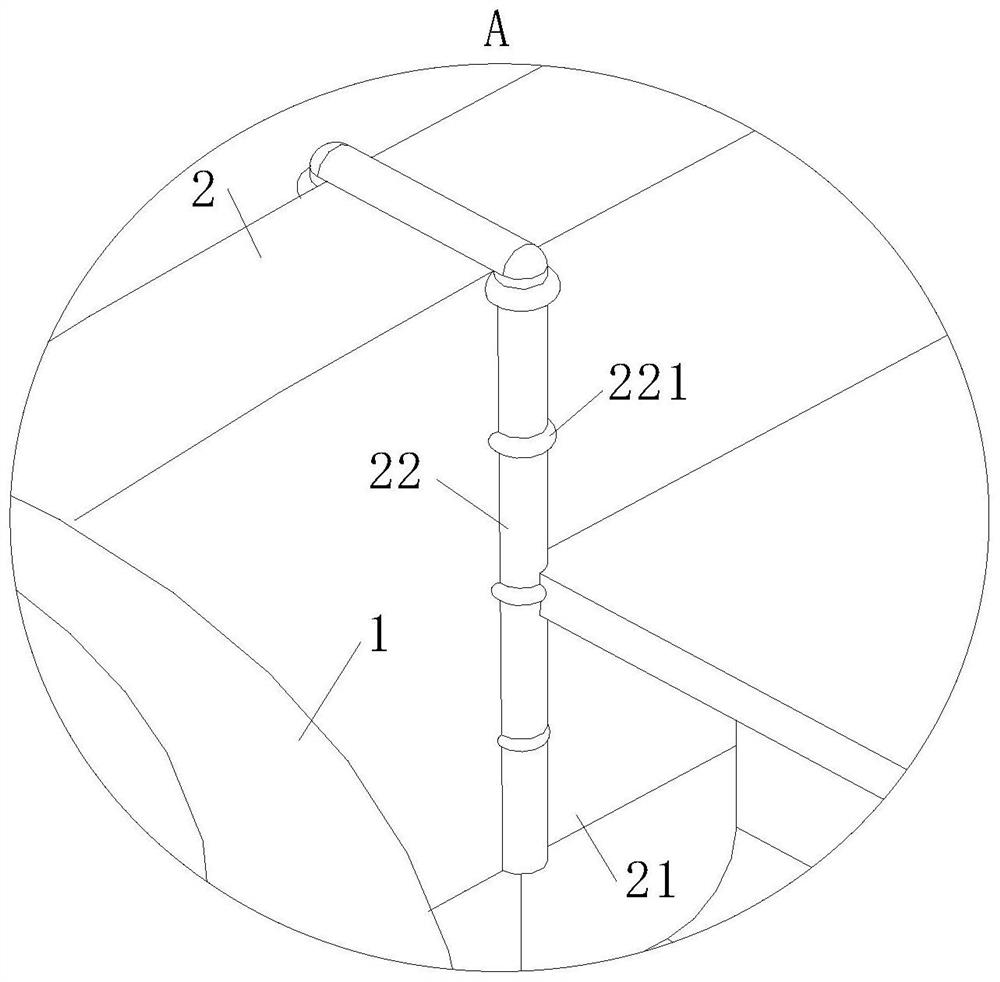

[0029] As an embodiment of the present invention, a plurality of sliding bodies 1 are installed on the detection track 2, and the bodies 1 are respectively located on the detection tracks 2 above the two conveyor belts 4, and the distance between the bodies 1 is its own distance. Length; the food to be detected on the conveyor belt 4 is placed together in contact with each other, and the body 1 used for infrared detection loses the detection function of the food in the arc bending area on the detection track 2, and then cannot reach It has a complete detection effect on food; multiple bodies 1 arranged on the detection track 2 cooperate with the two conveyor belts 4 under the circular detection track 2, and the infrared light source in it is 3 The food on the conveyor belt 4 is detected at intervals, and the food on the two conveyor belts 4 below the detection track 2 is controlled to be detected by the infrared light source 3 on the body 1 at intervals, which prevents the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com