Production method of microbial agent for waste purification

A technology for purification of microorganisms and production methods, applied in the methods of using microorganisms, methods of supporting/immobilizing microorganisms, methods of sterilization, etc., can solve the problems of reducing waste efficiency, inactivation, unsolved problems, etc., to improve the application effect, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

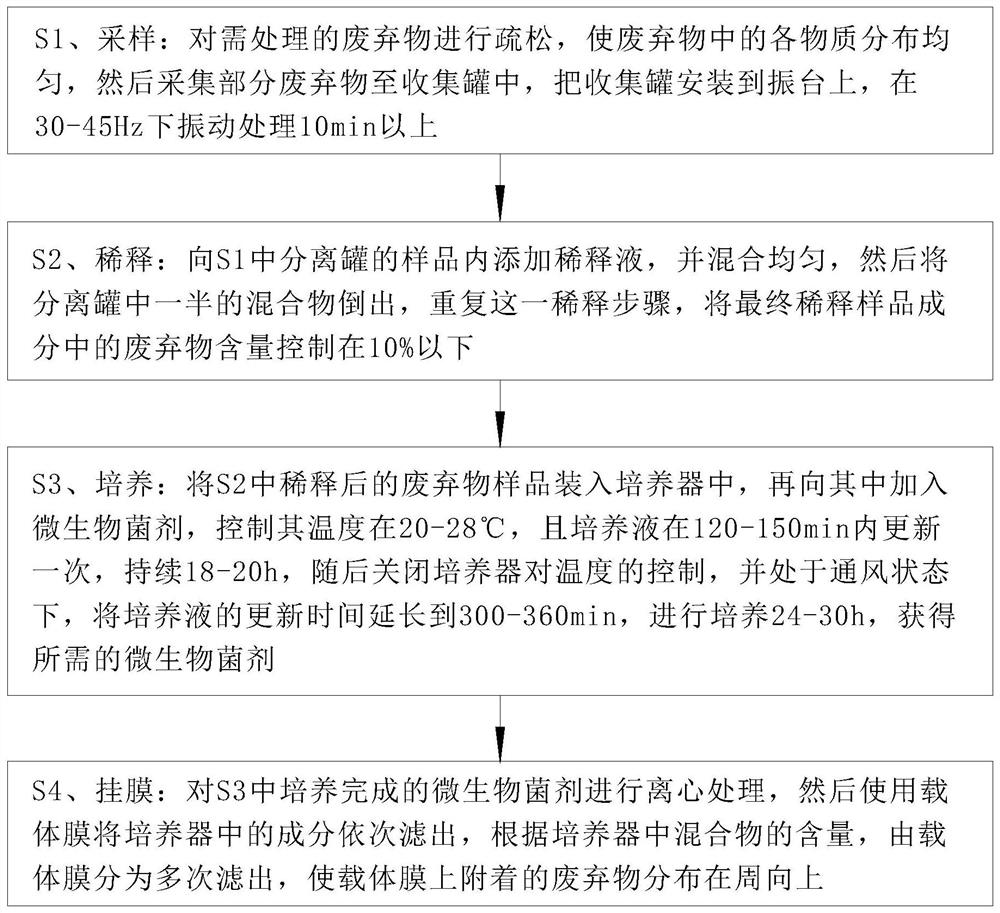

Method used

Image

Examples

Embodiment approach

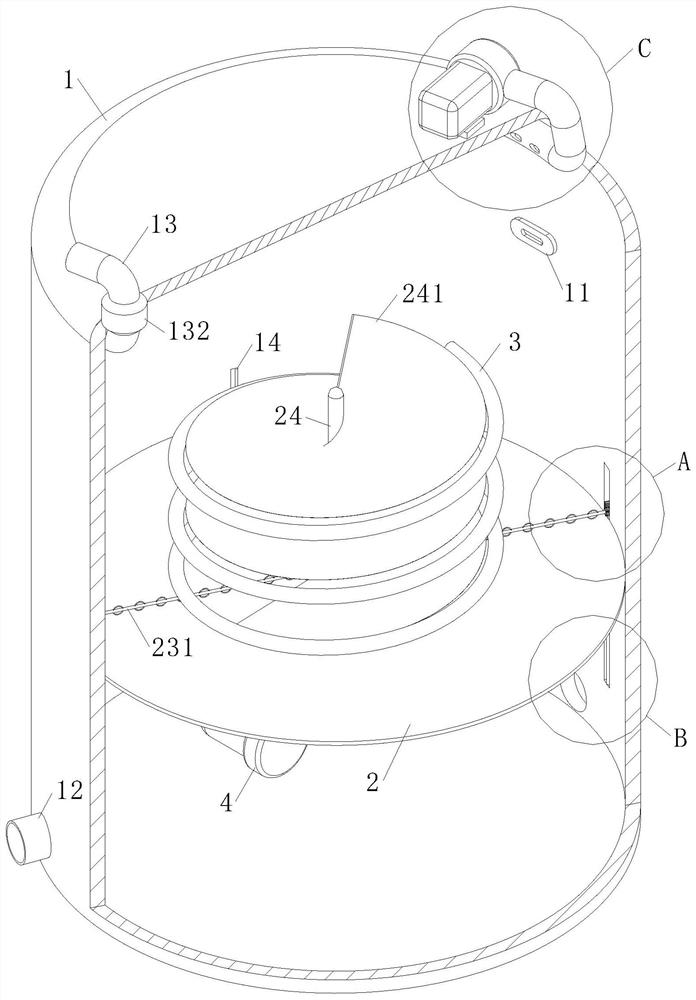

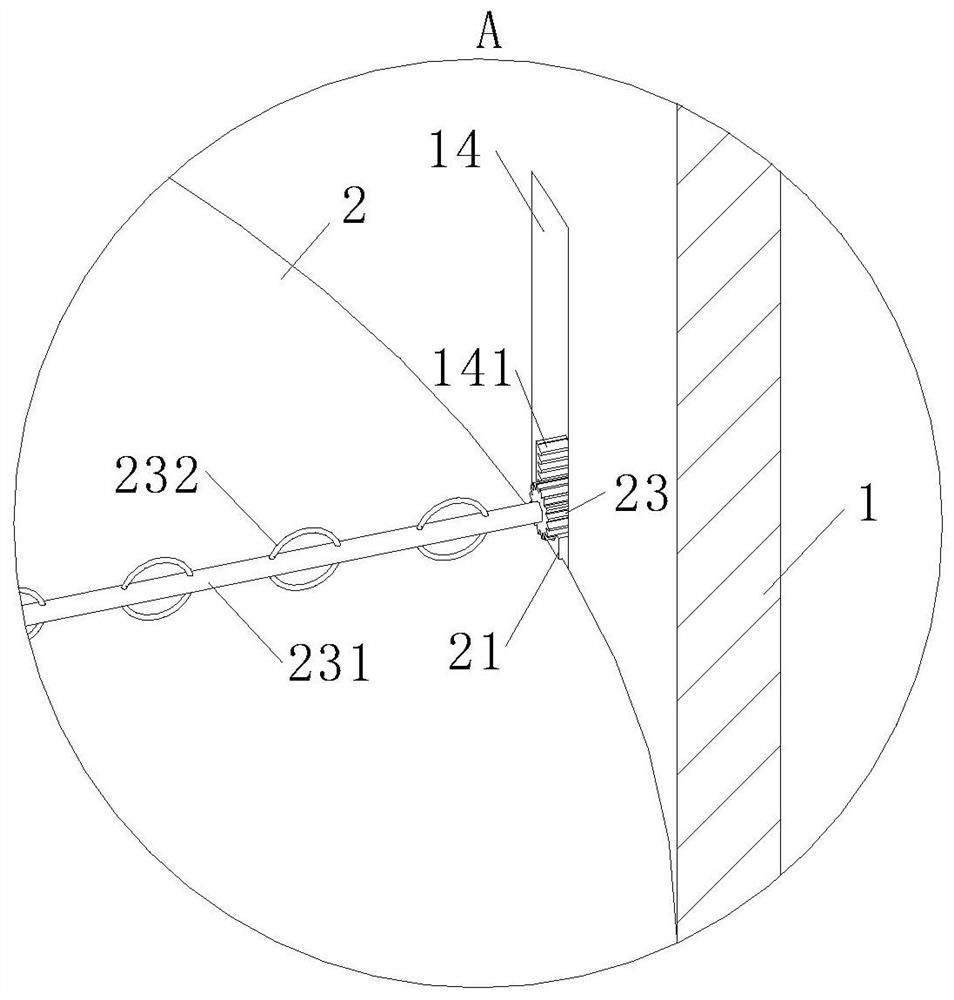

[0036] As an embodiment of the present invention, the protrusion 21 is provided with a roller tooth 23, and the chute 14 corresponding to the roller tooth 23 is provided with a rack 141; the roller tooth 23 is provided with a fixed lever 231, The driving rod 231 is provided with staggered convex rings 232, and the driving rod 231 rotates with the roller teeth 23 so that the convex rings 232 hit the surface of the diaphragm 2; The waste gas components in the pore diameter of the disc 2 will adhere and block on its surface, gradually reducing the filtering effect of the membrane disc 2 on the metabolites in the body 1; The tooth 23 is meshed with the rack 141 in the chute 14, so that the displacement generated by the diaphragm 2 during shaking drives the driving rod 231 to rotate, and the convex ring 232 on the driving rod 231 acts on the surface of the diaphragm 2, so that the diaphragm The clogged waste particles in the disk 2 are bounced, avoiding the accumulation of waste pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com