Controllable hydrogen production composite material and application thereof

A composite material and feed technology, applied in the field of hydrogen science, can solve the problems of slow hydrogen production and difficulty in achieving controlled release of hydrogen, and achieve the effect of improving the reduction activity, improving the ability to scavenge toxic free radicals, and solving the problem of excessive hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

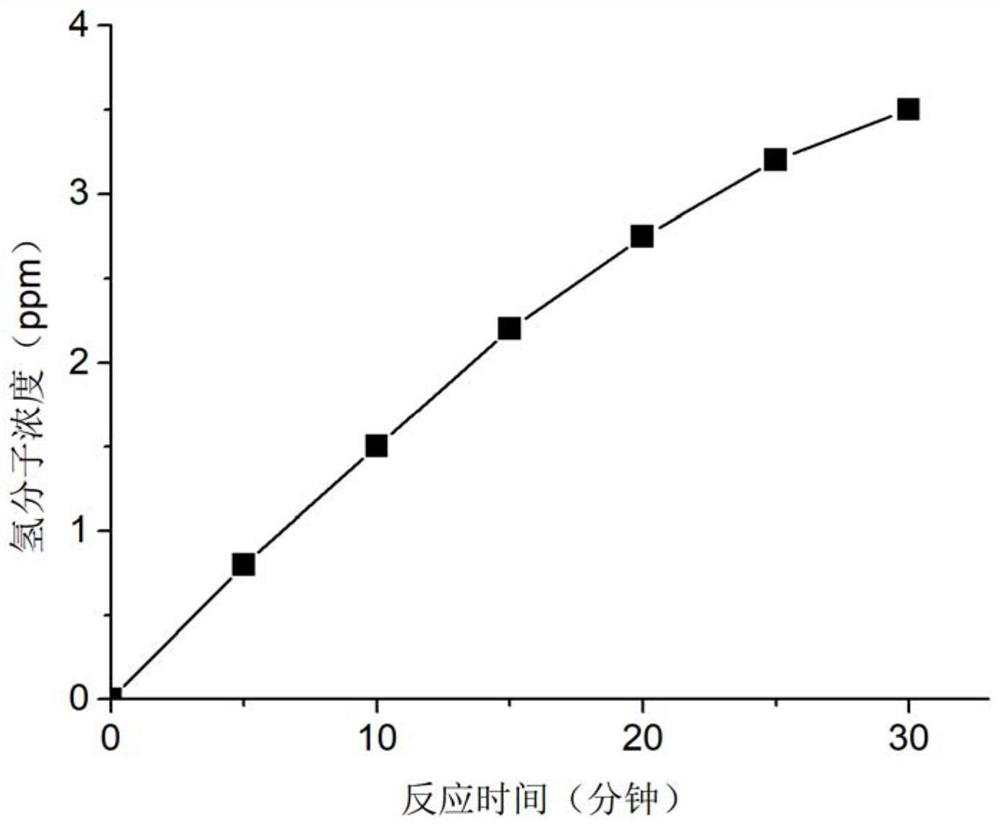

[0026] Configure 0.3% acetic acid solution as a controlled release agent, add 20mg of the above-mentioned controllable hydrogen production composite material, shake well, immediately generate a large number of micro-nano bubbles, and measure the hydrogen concentration as high as 3.5ppm with methylene blue titration solution after 30 minutes, as figure 1 shown. This formula can be used as a dry and wet mixed mask additive to continuously supply hydrogen at a high concentration and remove facial inflammation. The rate and concentration of hydrogen release can be adjusted by adjusting the amount of release-controlling agent.

Embodiment 2

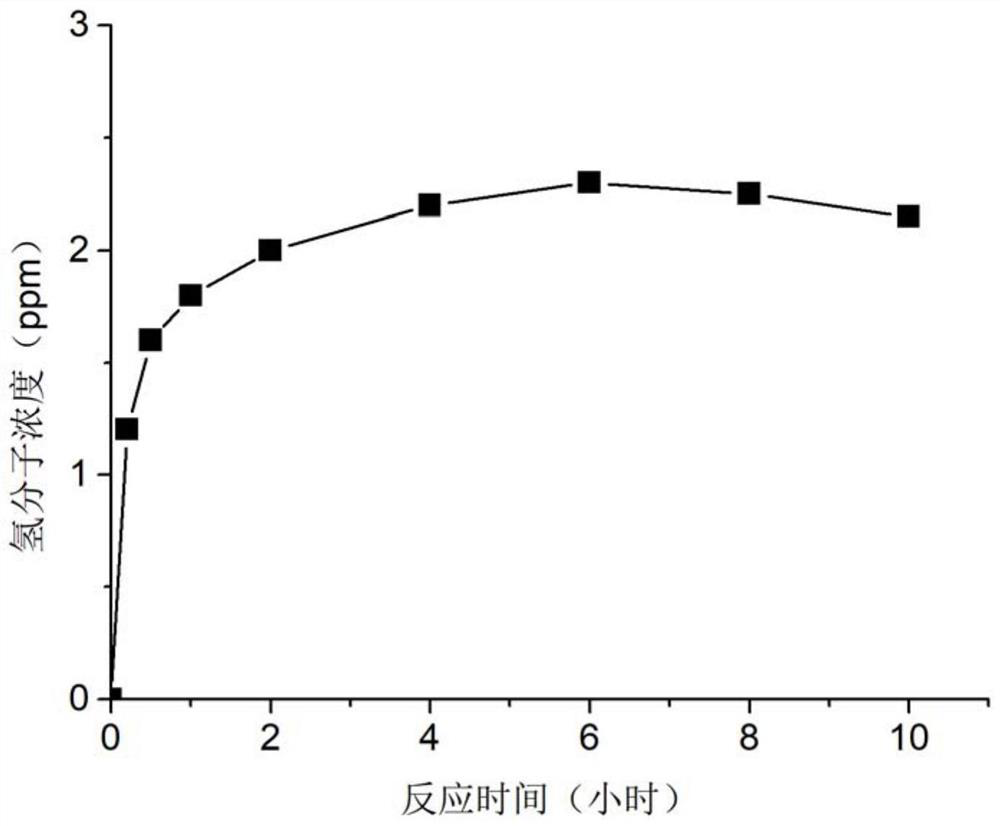

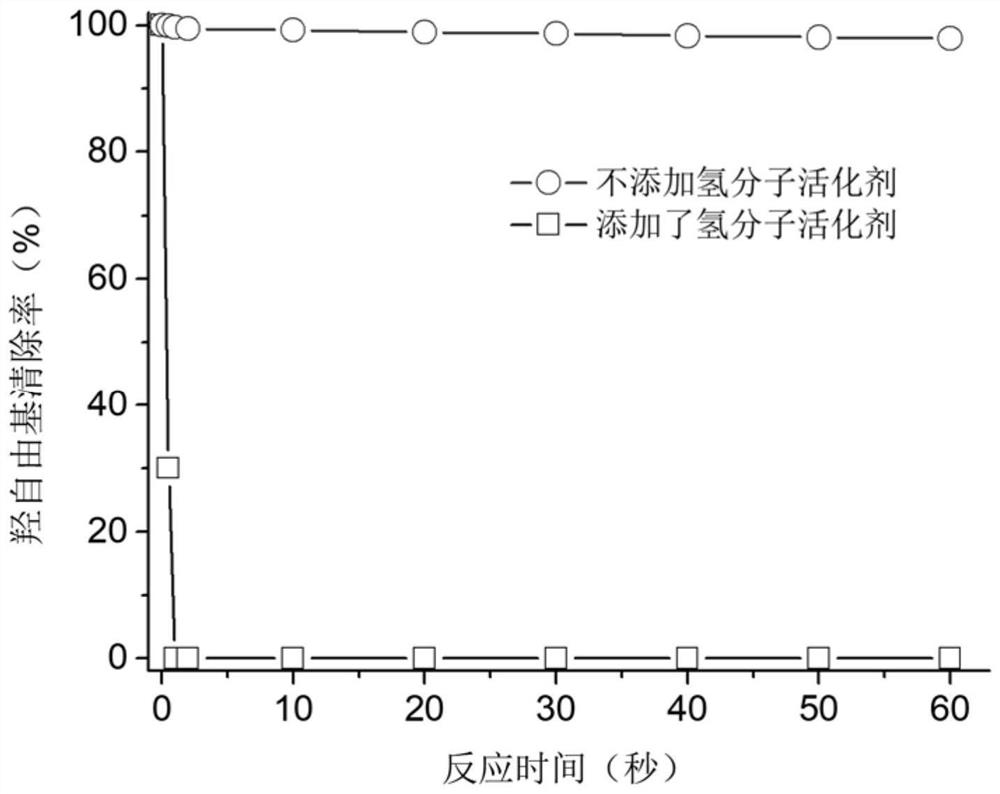

[0028] Take 100 mg of the above-mentioned controllable hydrogen production composite material, mix it well with 1 mg of hydrogen molecule activator and 400 mg of sodium carboxymethylcellulose, and press it into small pills. Adding small pills into the simulated gastric acid solution can produce hydrogen continuously for more than 10 hours, such as figure 2 shown, and rapidly eliminate hydroxyl radicals under the catalysis of hydrogen molecular activators, such as image 3 As shown, it is beneficial to long-term and convenient removal of gastrointestinal inflammation, improvement of intestinal flora, and improvement of human immunity. By adjusting the content of sodium carboxymethyl cellulose, the slow release rate of hydrogen can be controlled, and the content of the hydrogen molecule activator can be adjusted to control the scavenging rate of hydroxyl radicals.

Embodiment 3

[0030]The above-mentioned controllable hydrogen production composite material is uniformly mixed with disintegrants such as sodium bicarbonate, and pressed into hydrogen-rich effervescent tablets. Put the hydrogen-rich effervescent tablet into mineral water, fruit juice, milk, coffee, cola and herbal tea, etc., it will dissolve immediately and generate a large amount of hydrogen gas, and quickly form a super-saturated hydrogen-rich drink for instant drinking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com