Overlock structure, clothes applying overlock structure and manufacturing process

A manufacturing process and seaming technology, which is applied in the field of clothing seaming production, can solve the problems of seaming looseness and other problems, and achieve the effect of not easy to loose, good uniformity, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The embodiment of the present application discloses an overlock structure.

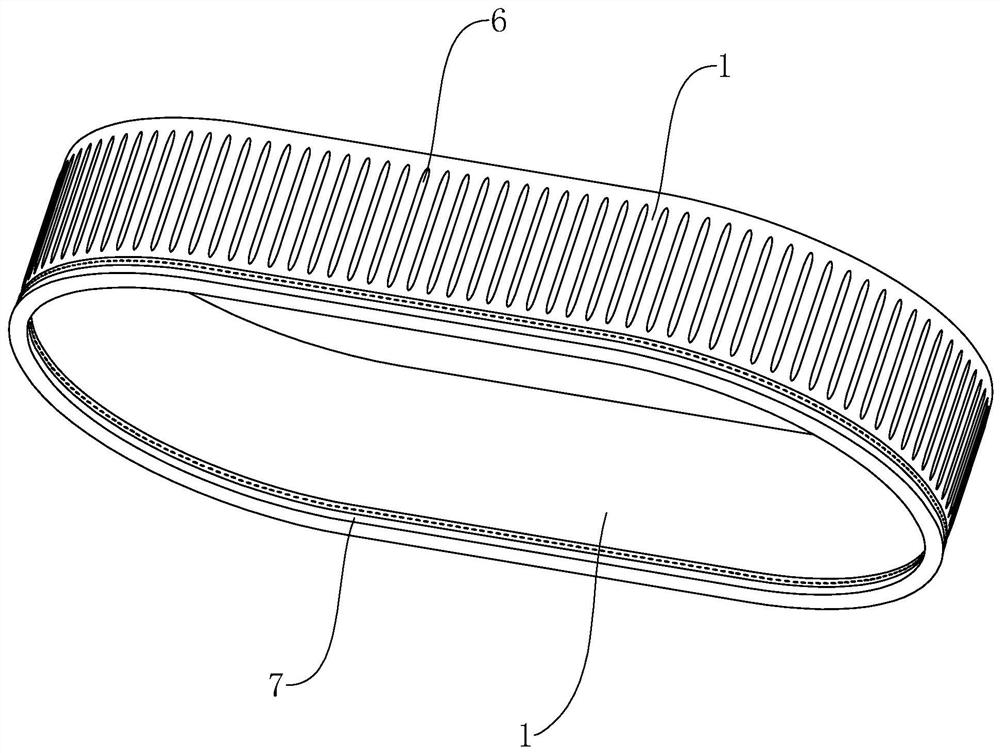

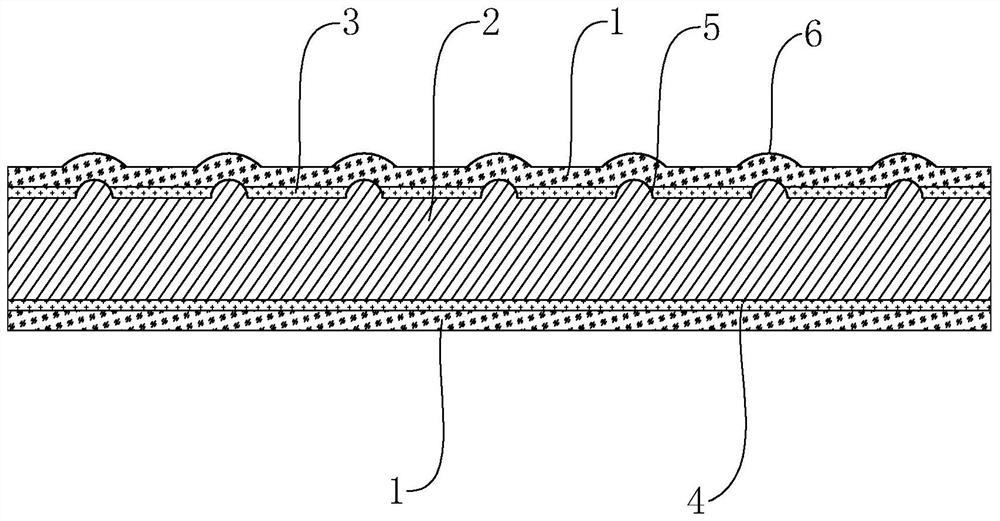

[0048] refer to figure 1 and figure 2 A hemming structure includes a hem and a hem 7 arranged on one side of the hem, the hem includes an elastic layer 2, a first adhesive layer 3, a second adhesive layer 4 and two layers of fabric 1, wherein one layer of fabric 1 is fixed on one side of the elastic layer 2 through the first adhesive layer 3, and another layer of fabric 1 is fixed on the other side of the elastic layer 2 through the second adhesive layer 4.

[0049] refer to figure 2 , in this overlock structure, the elastic layer 2 is made of beef tendon, and the beef tendon is made of polypropylene and latex silk. The beef tendon itself has good ductility, toughness and elasticity, and has a strong structure and long service life. The elastic layer 2 of beef tendon is used in the overlock structure, so that the overlock structure has better elastic elasticity, so that in the process of b...

Embodiment 2

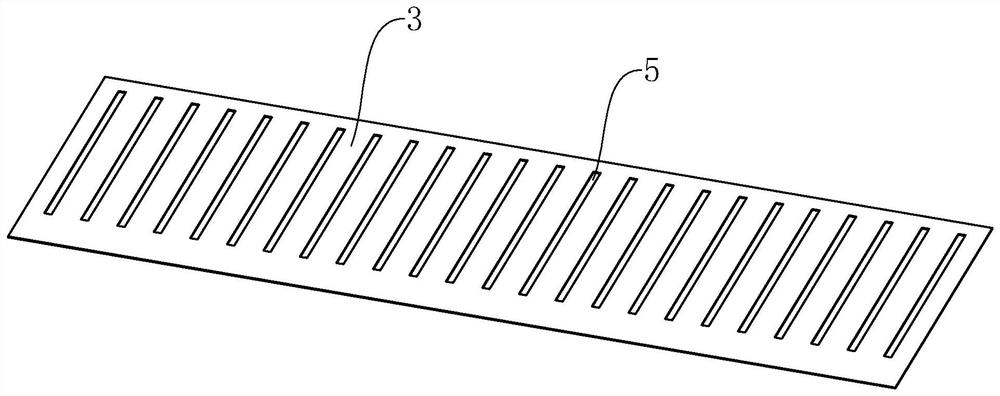

[0070] refer to Figure 5 and Figure 6 , the difference between this embodiment and Embodiment 1 is that it is an overlock structure, no holes 5 are cut on the first adhesive layer 3, and several strip-shaped holes are formed on the second adhesive layer 4 by laser cutting. holes 5 , and keep several holes 5 arranged equidistantly along the length direction of the second adhesive layer 4 .

[0071] refer to Figure 5 , due to the existence of several equidistantly arranged holes 5, the clothes hem can be loosened after the tight clothes hem is hot-pressed and shaped, at this time, under the action of the elastic restoring force of the elastic layer 2, the whole clothes hem retracts, here During the process, the elastic layer 2 will be extruded from a number of equidistantly arranged holes 5 on the second adhesive layer 4 and pressed against the fabric 1, thereby forming several equidistant holes on the fabric 1 on the second adhesive layer 4 side. Arranged drum kits6.

[...

Embodiment 3

[0081] refer to Figure 7 and Figure 8 The difference between this embodiment and Embodiment 1 is that a seam lock structure is cut to form several strip-shaped holes 5 on the first adhesive layer 3 and the second adhesive layer 4 by laser cutting, and Keep several holes 5 arranged equidistantly along the length direction of the first adhesive layer 3 and the second adhesive layer 4, while keeping the holes 5 on the first adhesive layer 3 and the holes 5 on the second adhesive layer 4 interlaced .

[0082] refer to Figure 7 , due to the existence of several equidistantly arranged holes 5, the clothes hem can be loosened after the tight clothes hem is hot-pressed and shaped, at this time, under the action of the elastic restoring force of the elastic layer 2, the whole clothes hem retracts, here During the process, the elastic layer 2 will be extruded from several equidistantly arranged holes 5 on the first adhesive layer 3 and the second adhesive layer 4 and pressed against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com