Polishing device for bearing production

A bearing production and grinding table technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding racks, etc., can solve the problems of troublesome cleaning, cumbersome operation, and poor grinding effect, and achieve convenient operation and convenient grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

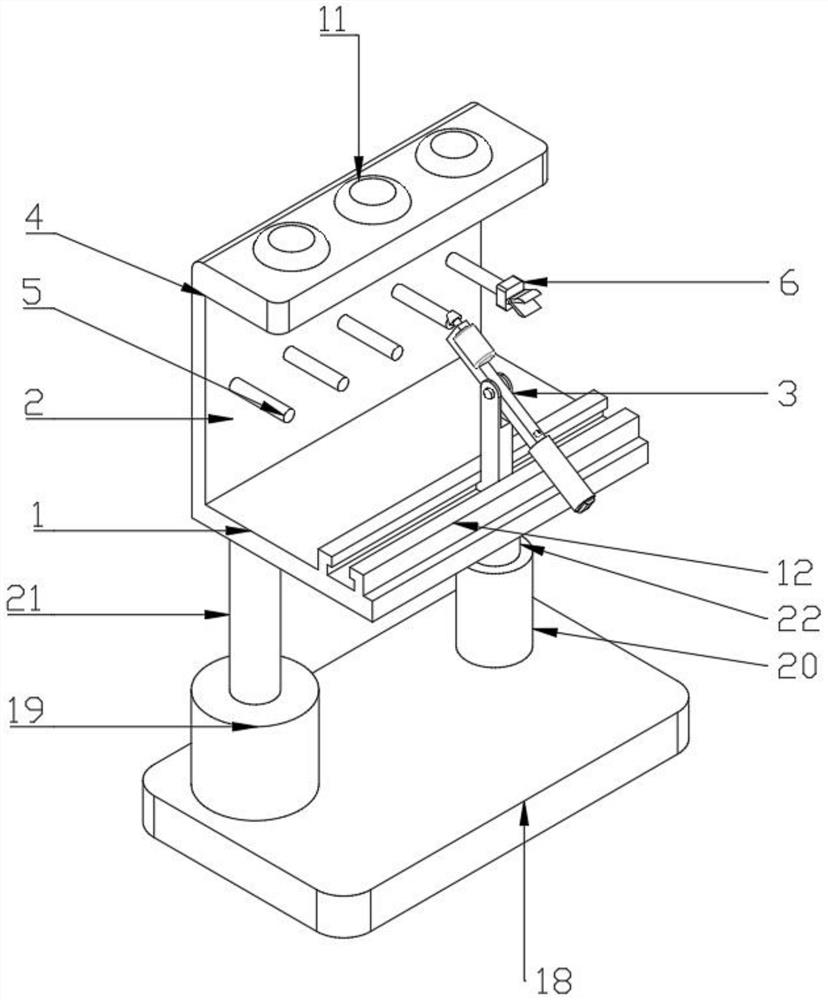

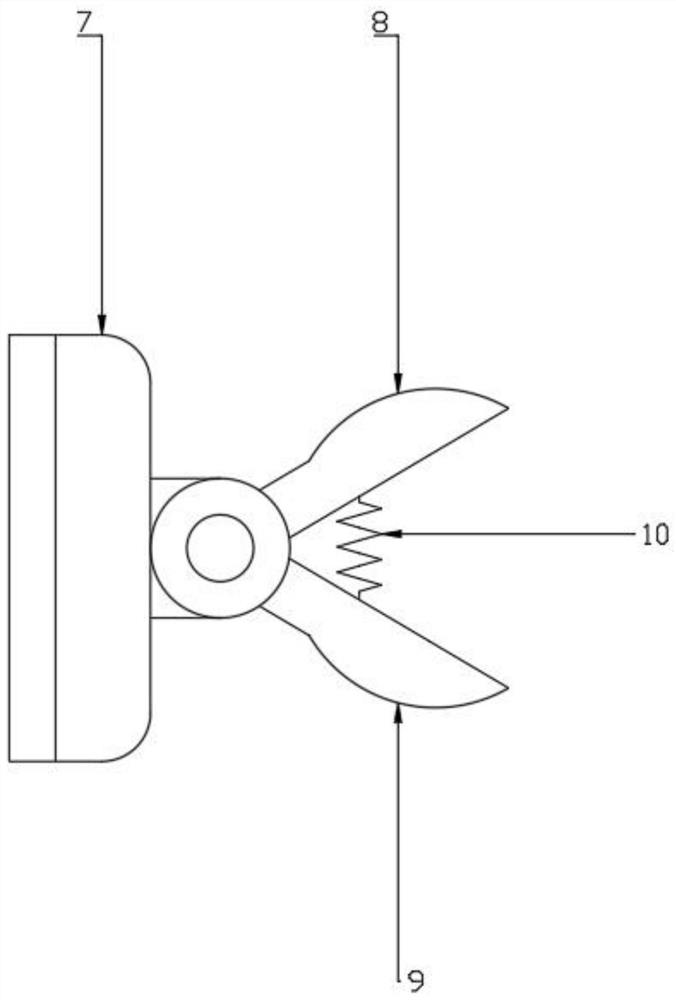

[0020] see Figure 1~3 , in Embodiment 1 of the present invention, a grinding device for bearing production includes a grinding table 1, a fixing mechanism 2 and a grinding mechanism 3, the fixing mechanism 2 includes a support plate 4, a cantilever 5 and a fixing head 6, the The support plate 4 is fixedly connected to the upper side of the upper surface of the grinding table 1 by welding, and is used to support the fan 11 and the fixed head 6. The front surface of the support plate 4 is linearly arranged and fixedly connected by welding. The cantilever 5, the front end of the cantilever 5 is fixedly connected with the fixed head 6 through threaded connection, the fixed head 6 includes a rear fixed plate 7, an upper pressure plate 8, a lower pressure plate 9 and a spring 10, and the front end of the rear fixed plate 7 passes through The lock chain is rotatably connected with the upper pressing plate 8 and the lower pressing plate 9, and the spring 10 is fixedly connected by we...

Embodiment 2

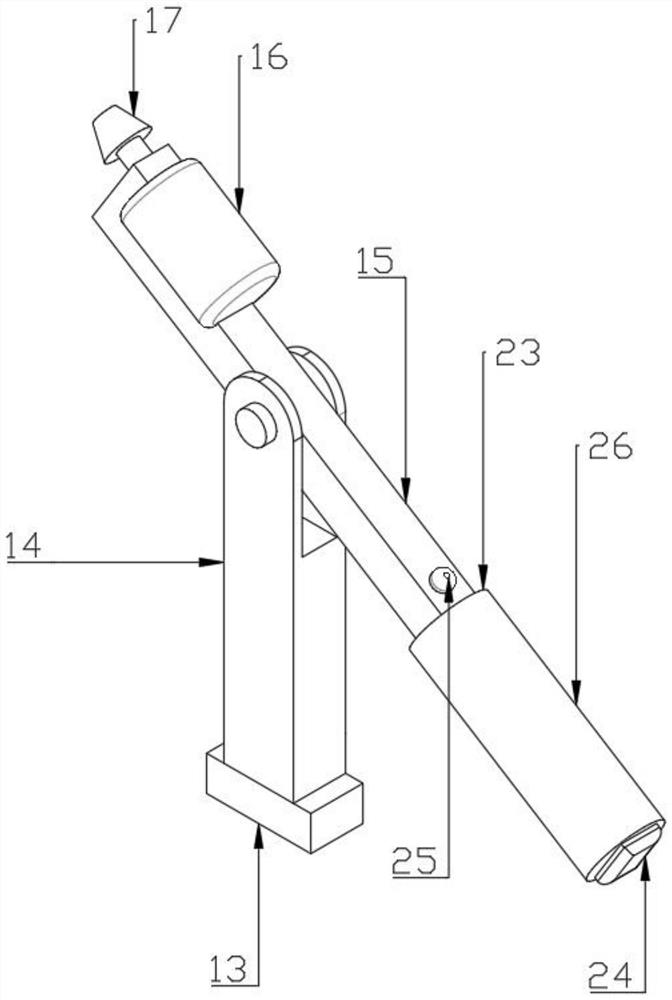

[0023] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the grinding device for bearing production includes a base 18, a pneumatic cylinder 19 and a support column 20, and the pneumatic cylinder 19 is fixedly connected to the base 18 through a threaded connection. The left side of the upper surface is used to adjust the height of the grinding table 1 , and the support column 20 is fixedly connected to the right side of the upper surface of the base 18 by welding. The grinding device for bearing production includes a drive shaft 21 fixedly connected to the output end of the pneumatic cylinder 19 through a threaded connection. The grinding device used for bearing production includes a driven shaft 22, which is slidably connected to the support column 20 by clamping, and the upper surfaces of the driving shaft 21 and the driven shaft 22 are fixed by screw connections The grinding table 1 is connected, and the height of the entire grinding ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com