Isolated container interior glazing equipment for ceramic processing

A ceramic processing and isolation technology, which is applied to the field of glazing equipment inside an isolation container for ceramic processing, can solve the problems of lack of protective measures, low efficiency, glaze drifting around, etc., to prevent glaze from drifting out and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

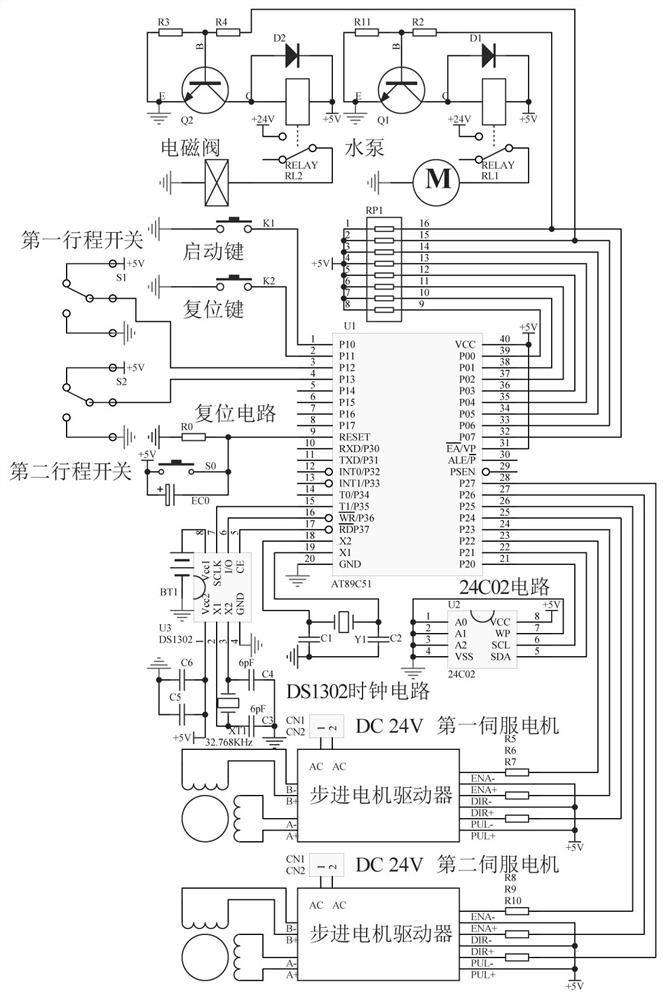

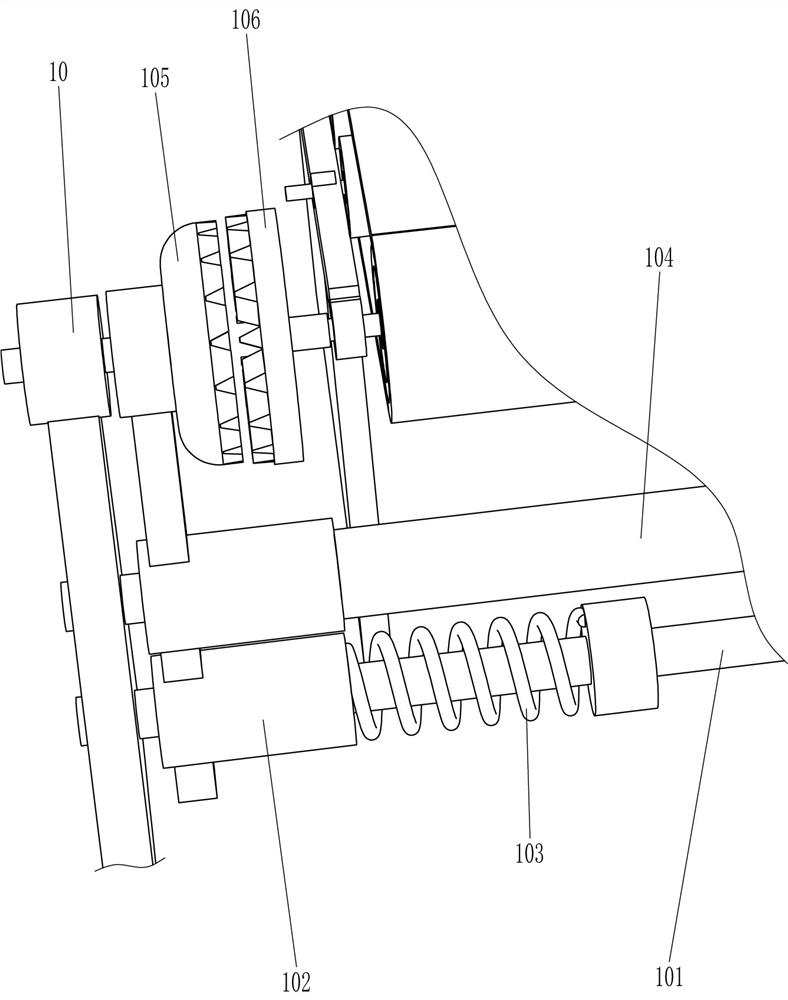

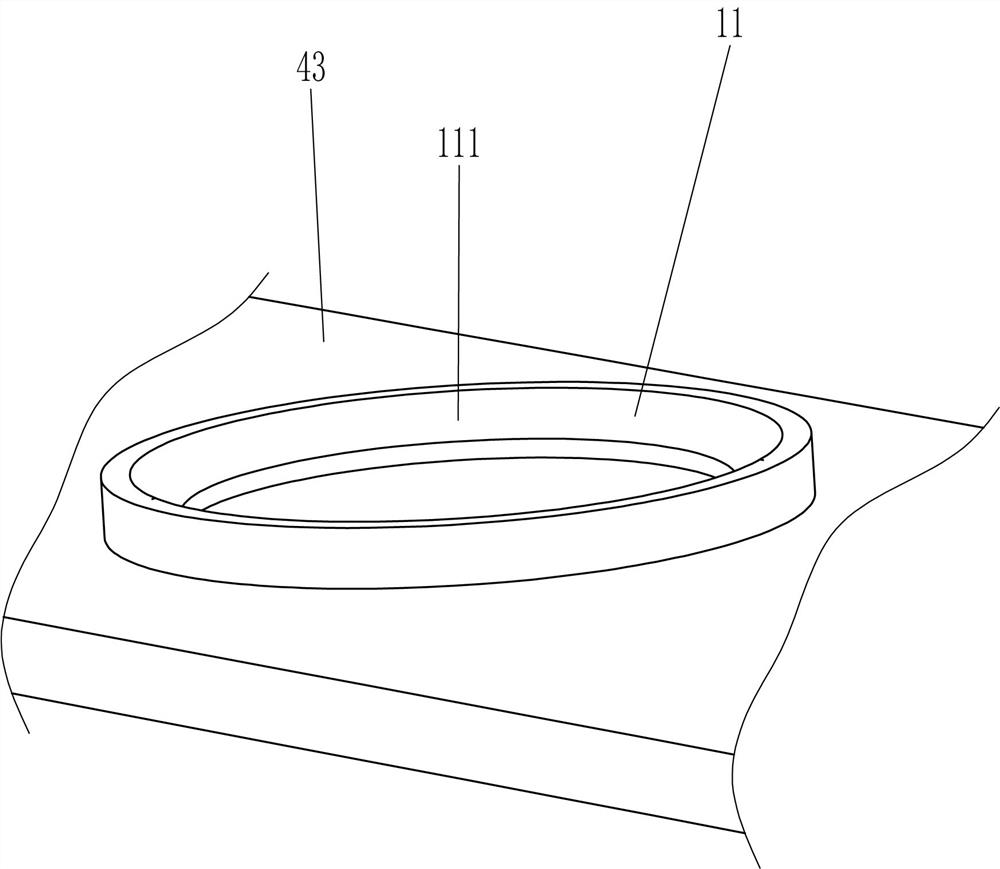

[0036] A kind of glazing equipment inside an isolated container for ceramic processing, such as Figure 1-6As shown, it includes installation platform 1, roller frame 41, conveyor belt 42, placement plate 43, driving mechanism 5, moving mechanism 6, booster mechanism 7 and spraying mechanism 8, and rollers are installed on the left and right sides of the top of installation platform 1 Frame 41, a conveyor belt 42 is wound around the two roller frames 41, and the outside of the conveyor belt 42 is connected with a placement plate 43 at even intervals. A spraying mechanism 8 is installed on the mechanism 6 , and a booster mechanism 7 is installed on the rear side of the mounting table 1 .

[0037] When it is necessary to glaze the interior of the ceramics, the staff will neatly place a plurality of ceramics on the placement plate 43, then press the main power switch to power on the device, and then press the start key, which sends a signal to control After receiving the signal,...

Embodiment 2

[0047] On the basis of Example 1, such as image 3 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the leak-proof mechanism 9 is also included, and the leak-proof mechanism 9 includes a bracket 91, a second guide sleeve 92, a second guide rod 93, a fourth spring 94, a hinged cover plate 95 and an elastic cord 96, and the bottom of the cylinder body 81 Connected with a bracket 91, the bracket 91 is connected with a second guide sleeve 92, the second guide sleeve 92 is slidably provided with a second guide rod 93, the second guide rod 93 runs through the protective cover 88, and the second guide rod 93 is covered with The fourth spring 94, the two ends of the fourth spring 94 are respectively connected with the second guide sleeve 92 and the second guide rod 93, the bottom end of the second guide rod 93 is rotatably connected with a hinged cover 95, the hinged cover 95 is connected with the nozzle 86 In contact, an elastic cord 96 is connected between the hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com