A stacking and handling device for hollow bricks

A technology for handling devices and hollow bricks, which is applied in the direction of object stacking, transportation and packaging, conveyor objects, etc., and can solve the problems of poor handling stability and fast transfer speed of hollow bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

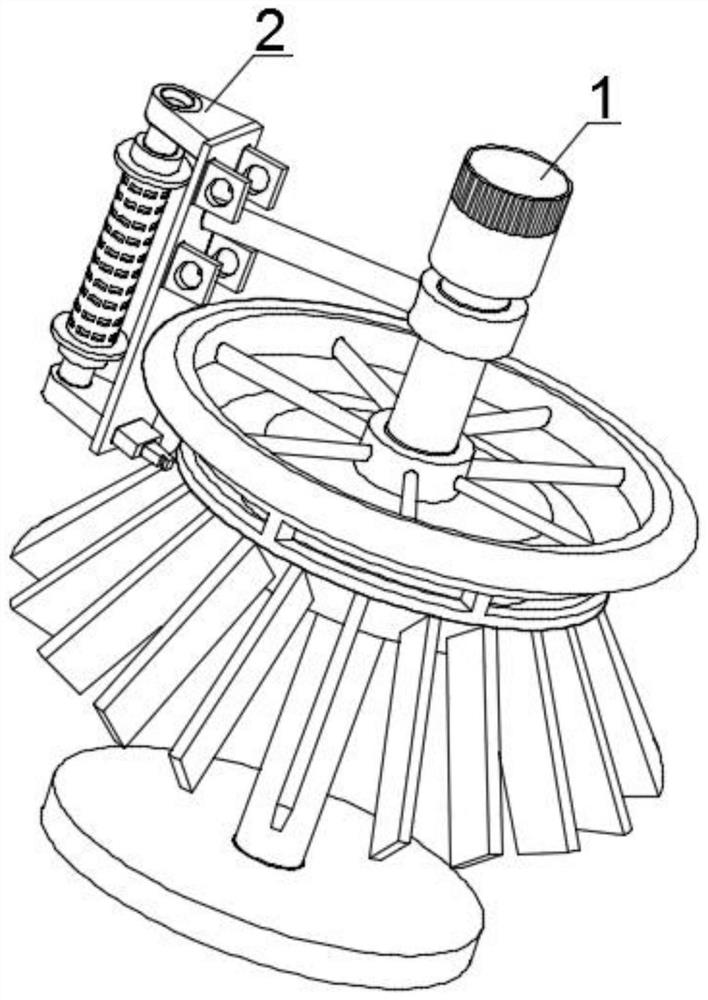

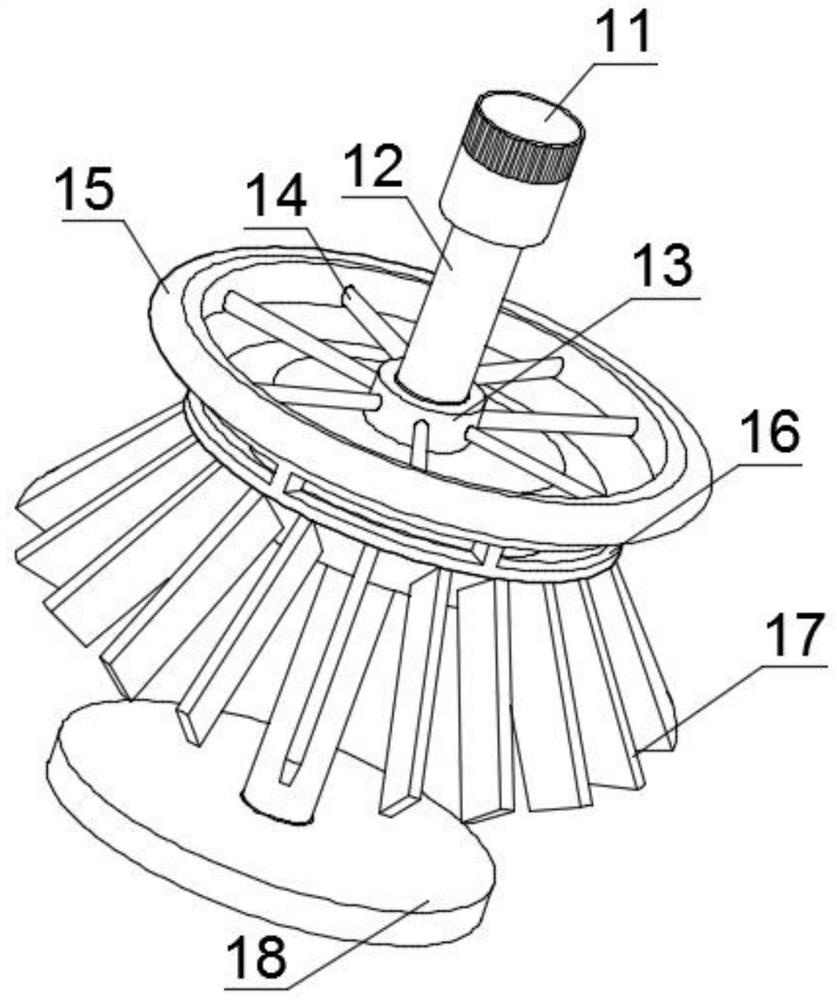

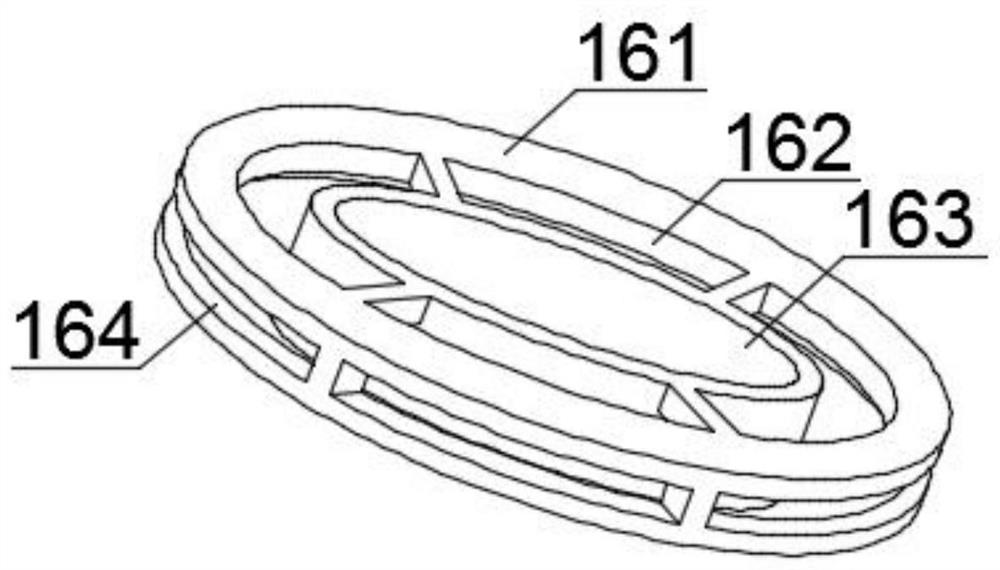

[0028] Such as Figure 1-3 As shown, a stacking and handling device for hollow bricks includes a driving mechanism 1 and a transfer mechanism 2. The driving mechanism 1 includes a driving motor 11, a transmission shaft 12, a coupling 13, an external rod 14, an outer rim 15, and an assembly ring 16. The limit soft strip 17 and the placement chassis 18, the lower end of the driving motor 11 is flexibly connected with the transmission shaft 12, the outer ring of the transmission shaft 12 is equipped with a coupling 13, and the outer ring array of the coupling 13 is provided with an outer ring. Rod 14, the outer end of the external connecting rod 14 is flexibly connected with the inner cavity wall of the outer rim 15, and the bottom end of the outer rim 15 is equipped with an assembly ring 16, and the assembly ring 16 includes a ring body 161, a top opening cavity 162, a built-in cavity 163 and edge cavity holes 164, the top of the ring body 161 is provided with a top opening cavi...

Embodiment 2

[0030] Such as Figure 4-7 As shown, the outer ring of the transmission shaft 12 is equipped with a transfer mechanism 2, the transfer mechanism 2 includes a connecting mechanism 21 and a limiting mechanism 22, the inner cavity of the connecting mechanism 21 is equipped with a limiting mechanism 22, and the connecting mechanism 21 includes an assembly riser 211, connecting Double-ear block 212, connecting column 213, assembly lug 214, support cross bar 215, surrounding block 216, inner opening cavity 217, assembly block 218 and limit hook block 219, the upper and lower sides of the left end of assembly vertical plate 211 are equipped with connecting double Ear blocks 212, connecting columns 213 are installed between the double ear blocks 212, assembly lifting lugs 214 are installed on the right end of the assembly vertical plate 211, and a support cross bar 215 is installed between the assembly lugs 214, and the other end of the support cross bar 215 Surrounding block 216 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com