Impact-resistant, low-temperature-resistant and high-transparency polypropylene composition

A transparent polypropylene, low temperature resistant technology, applied in polypropylene composition, low temperature resistant high transparent polypropylene composition, impact resistance field, can solve the problem that high transparent polypropylene cannot meet the environment below -20 ℃, cannot use high transparency Polypropylene materials, transparency can not be effectively improved and other problems, to achieve the effect of excellent rigidity and toughness balance, excellent low temperature toughness, high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

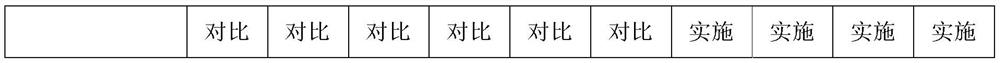

[0021] Weighing and mixing by weight formula, 1700 grams of random polypropylene powder weight, 1 gram of main antioxidant 1010 (German Basf) weight, 2 grams of auxiliary antioxidant 168 (German Basf), acid absorbent stearic acid Calcium (Italian hair base) 1 gram, nucleating agent Millad3988 (U.S. Milliken) weight 4 grams, vinyl elastomer Engage8150 (U.S. Dow Chemical) 200 grams, propylene-ethylene block copolymer Intune 5545 (U.S. Dow) chemistry) 100 g.

[0022] During preparation, the above-mentioned components are added into a high-speed mixer, stirred and mixed for 2 minutes, and discharged, mixed and granulated in a twin-screw extruder, and then the polypropylene resin particles are injected into standard specimens for testing. The temperature of the extruder is set to 180°C in the first zone, 190°C in the second zone, 200°C in the third zone, 210°C in the fourth zone, 210°C in the fifth zone, 210°C in the sixth zone, 210°C in the seventh zone, and 200°C for the head °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com