Phase modifier rotor packing cooling water leakage monitoring and analyzing device and application method

A technology of analysis device and camera, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of cooling water entering the excitation chamber, insufficient measurement data accuracy, and water accumulation in the excitation chamber and other problems, to achieve the effect of improving the efficiency of accident handling, strong scalability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings, but the specific embodiments do not limit the present invention in any way.

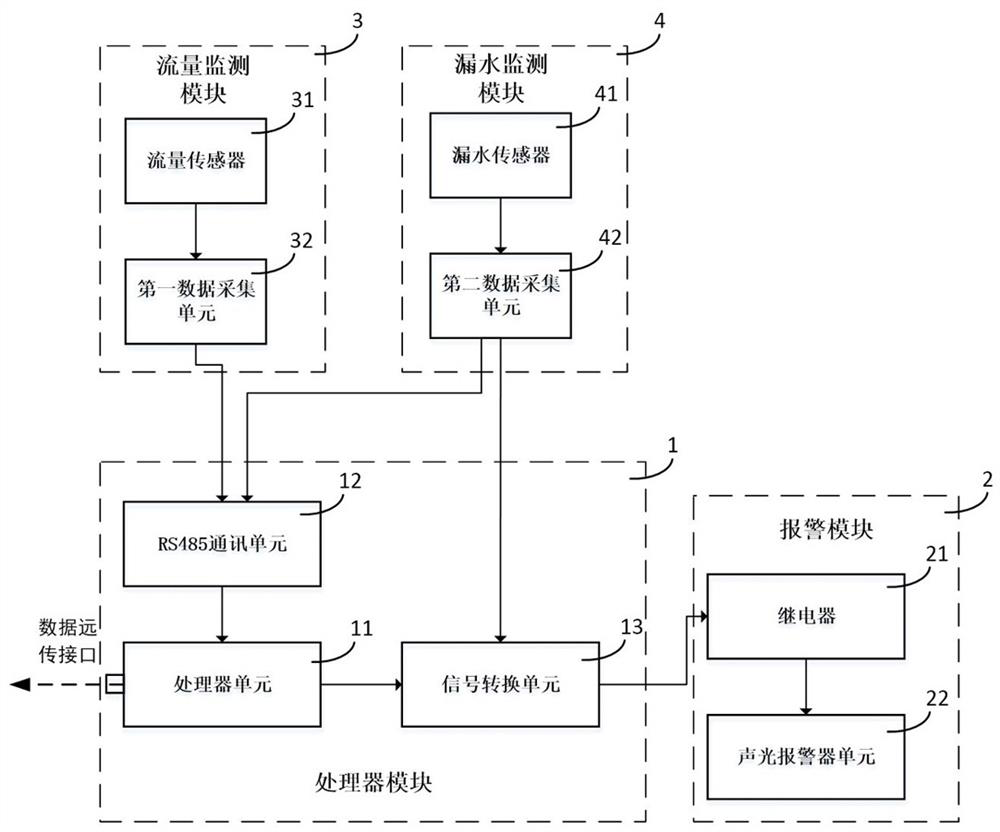

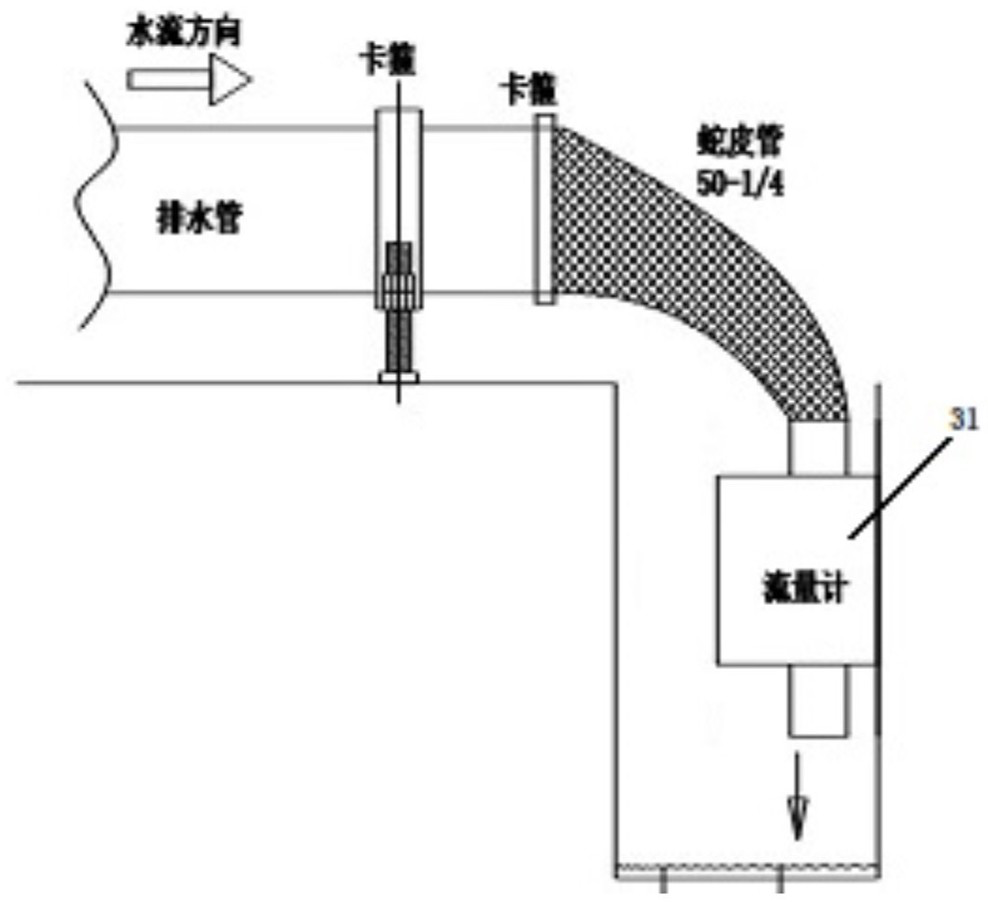

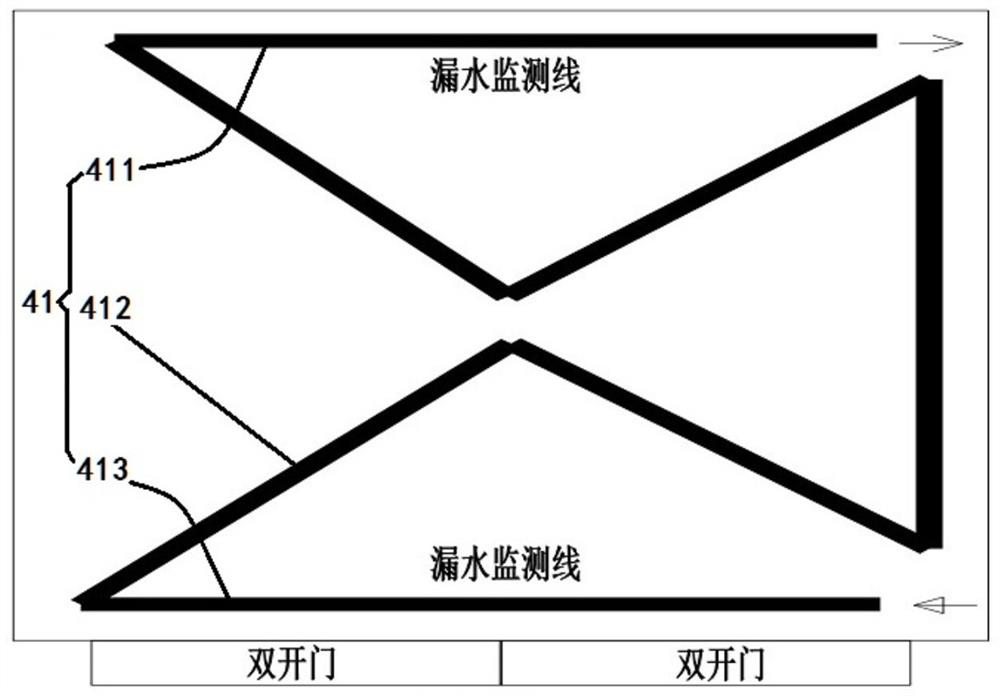

[0026] Such as figure 1 As shown, a device for monitoring and analyzing cooling water leakage of the condenser rotor packing of the present invention includes a processor module 1, an alarm module 2, a flow monitoring module 3 for monitoring the outlet water flow of the condenser rotor packing, and a flow monitoring module 3 for monitoring the The water leakage monitoring module 4 of the water leakage in the excitation chamber of the camera, the processor module 1 includes a processor unit 11 and a signal conversion unit 13, the input end of the processor unit 11 is respectively connected with the output end of the flow monitoring module 3, and the output end of the water leakage monitoring module 4 Connection, the output end of the processor unit 11 and the output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com