Pipe circumferential pure shearing loading method and device

A loading device, pure shearing technology, applied in the direction of measuring device, testing material strength by applying stable shear force, analyzing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

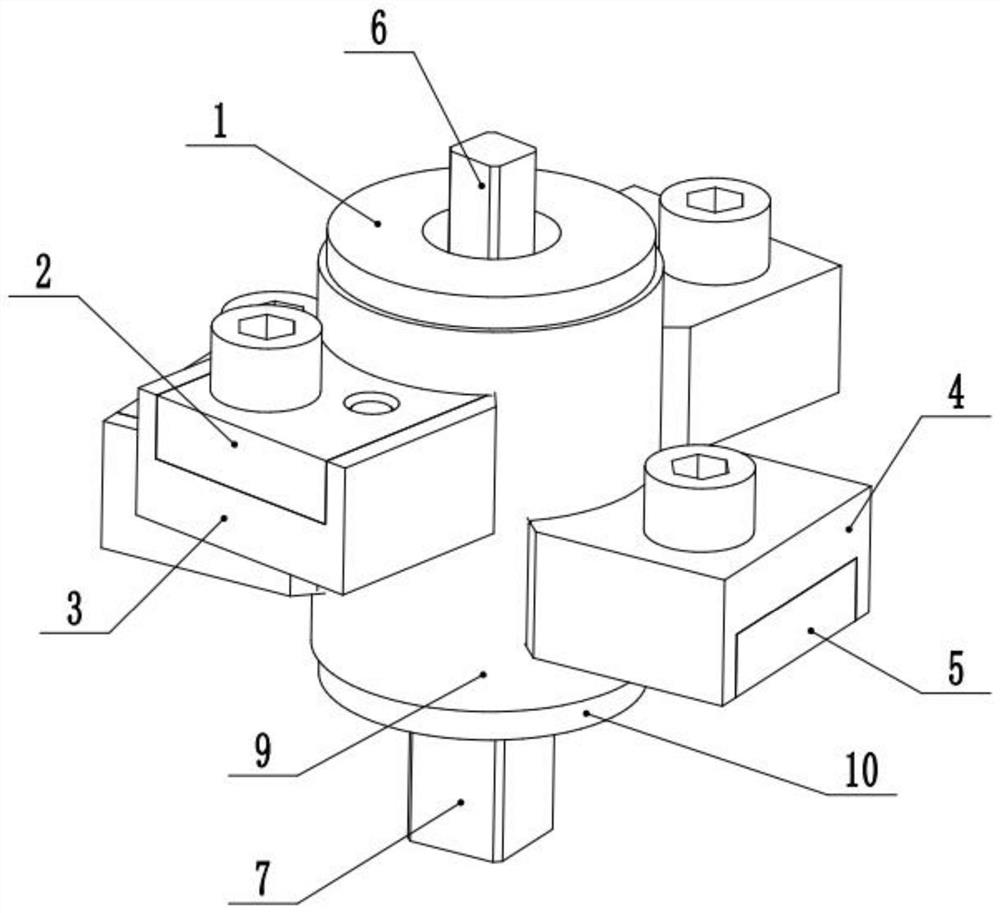

[0040] This embodiment provides a hoop pure shear loading method for pipes, such as Figure 1-8 shown, including:

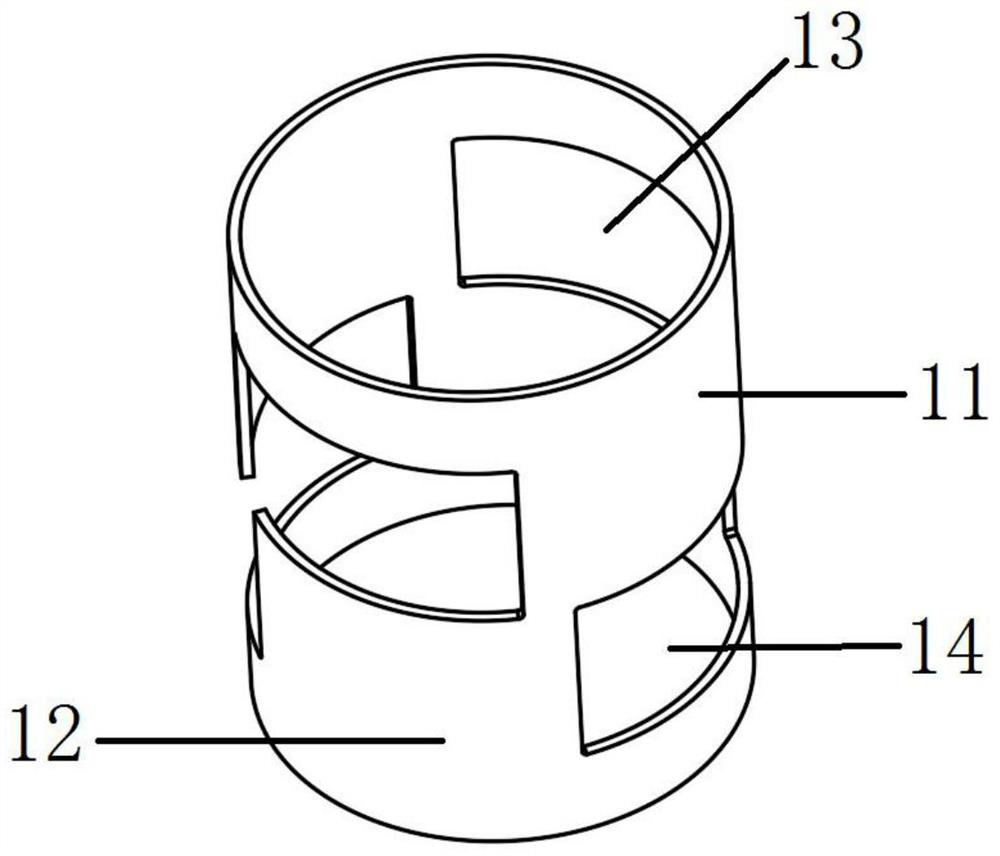

[0041] Step 1: Divide the pipe 9 to be detected axially into an upper pipe 11 and a lower pipe 12 through a circumferential dividing line located on the side wall of the pipe 9 to be tested. The plane where the circumferential dividing line is located is perpendicular to the axis of the pipe. On the side wall of the pipe material 9 to be detected, a first gap 13 extending upward to the pipe material 11 is provided from the ring to the boundary line, and a second gap 14 extending downward to the pipe material 12 is provided on the side wall of the pipe material 9 to be detected from the ring to the boundary line, and makes The upper pipe material 11 and the lower pipe material 12 form a state connected only by the connecting portion, such as figure 2 For the pipe style shown in , the number of connection parts can be one or more;

[0042] Step 2: Insert the man...

Embodiment 2

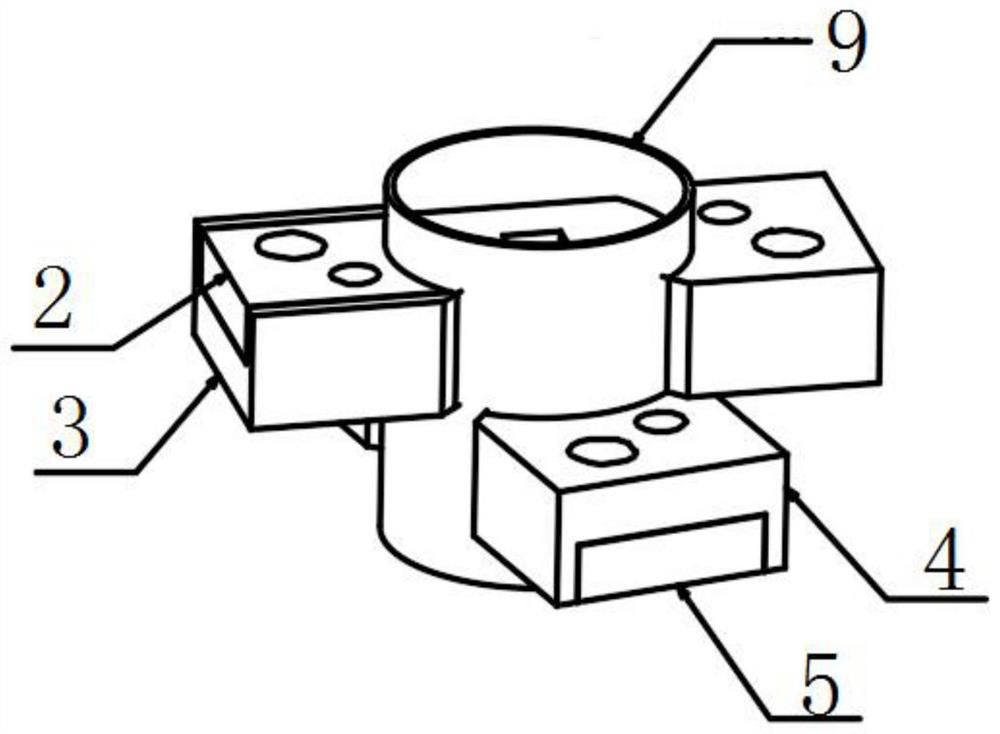

[0046] This embodiment provides a device for realizing the pipe hoop pure shear loading method described in Embodiment 1, such as Figure 1-8 As shown, it includes: a twisting device and a mandrel, the mandrel is used to be inserted in the pipe to be detected 9 along the axial direction of the pipe, the shearing surface 17 in the twisting device can be against the first edge and the second edge and can The first edge and the second edge respectively apply opposite and circumferential torsion forces along the pipe; the torsion device is also provided with several anti-deformation surfaces, and each anti-deformation surface is used to abut against the first notch 13 and the second notch respectively 14 On the remaining edges except the first edge and the second edge, each anti-deformation surface is respectively used to resist the deformation of each edge, therefore, the device provided in this embodiment can be used to realize the method in the first embodiment.

[0047] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com