A kind of acquisition method of grain orientation imaging map

A technology of grain orientation and acquisition method, applied in instruments, microscopes, optics, etc., can solve problems such as poor universality, achieve low cost, and solve the effect of increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

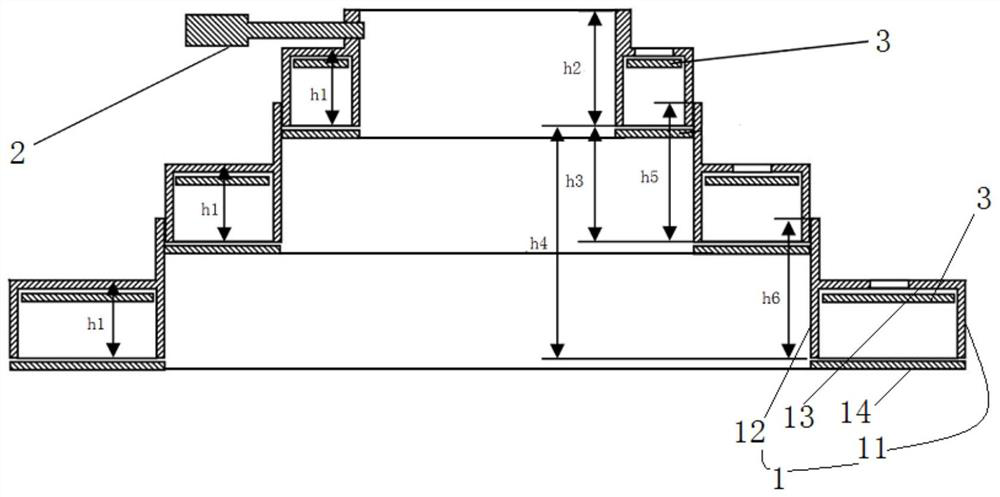

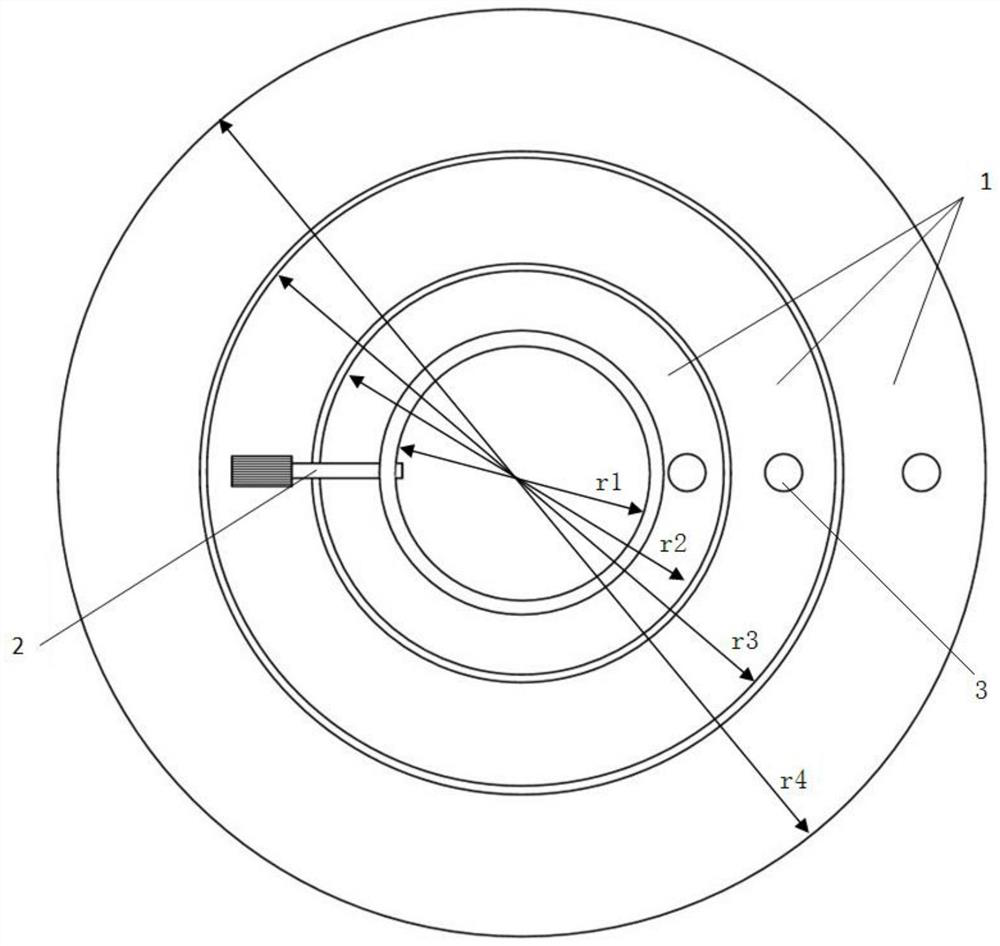

[0028] An auxiliary device for obtaining a crystal grain orientation imaging map of the present invention comprises: upper, middle and lower three-layer annular cavity bodies 1 fixed in a stepped manner, and the inner diameter of the three-layer annular cavity 1 decreases sequentially from bottom to top, The inner wall of the cavity 1 of the lower layer is fixedly connected with the outer wall of the cavity 1 of the middle layer, and the inner wall of the cavity 1 of the middle layer is fixedly connected to the outer wall of the cavity 1 of the upper layer;

[0029] The cavity 1 includes an outer surface body 11 , an inner surface body 12 , a top surface body 13 , and a bottom surface body 14 , which are sequentially fixed and closed to form a cavity; Ring surface light source;

[0030] The three-layer cavity 1 is equipped with an ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com