Surface anti-rust treatment equipment for parts used in the processing and manufacturing of hydraulic turbines

A processing and manufacturing, anti-rust treatment technology, applied in the direction of pre-treating the surface, applying liquid to the surface, coating, etc. It can solve the problem of poor uniformity of paint adhesion on the surface of parts, more labor consumption, and quality of anti-rust treatment. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

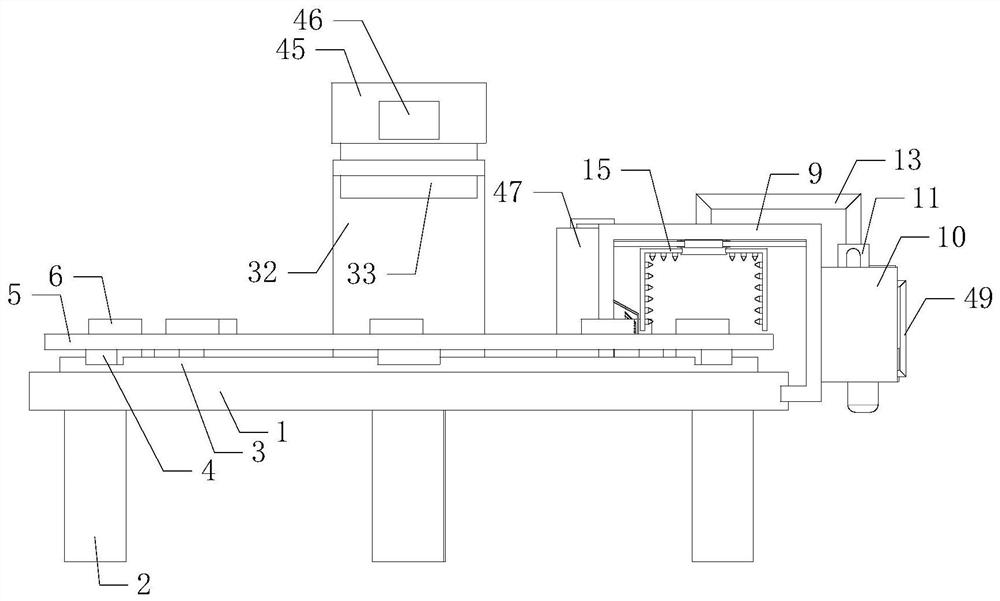

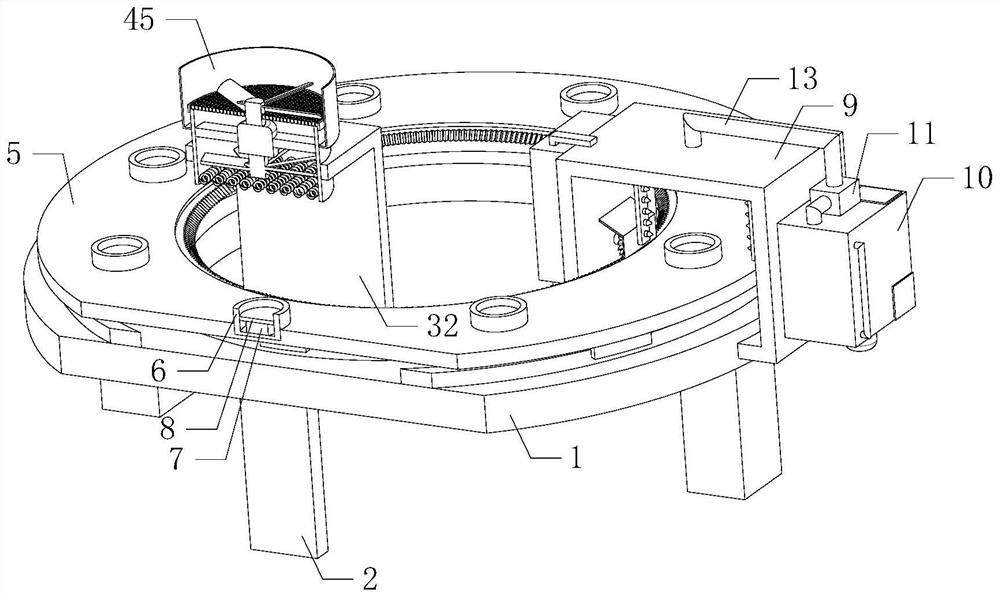

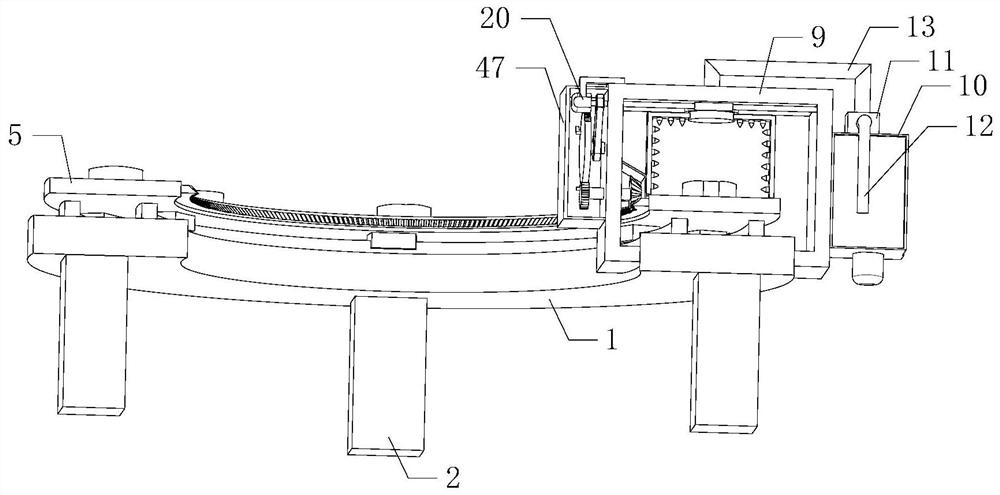

[0021] like Figure 1 to Figure 6 As shown in the figure, the surface anti-rust treatment equipment for the processing and manufacturing of the hydraulic turbine unit of the present invention turns on the first motor 20 during operation, the first motor 20 drives the first rotating shaft 18 to rotate, the first rotating shaft 18 drives the worm 19 to rotate, and the worm 19 meshes with the worm gear ring 17, the worm 19 drives the material guide bin 14 to rotate through the worm gear ring 17, and the material guide bin 14 drives two groups of right-angle bulk pipes 15 and multiple groups of nozzles 16 to rotate in a circular manner. The rotating shaft 18 drives the synchronous belt 24 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com