Cantilever mounting robot control system

A control system and robot technology, applied in the field of control, can solve problems such as difficult travel of lifting trolleys, cumbersome fixing steps, and high work intensity, and achieve the effects of saving manpower, convenient and accurate grasping, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment Wrist arm mounted robot control system

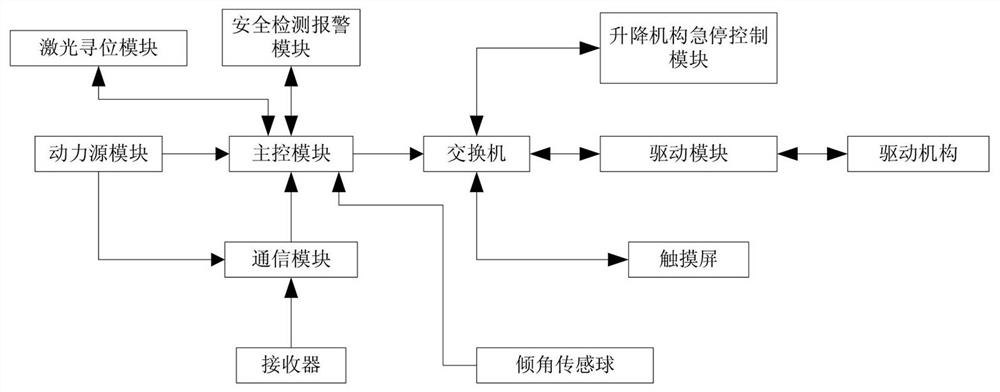

[0038] A wrist arm mounted robot control system, its structural block diagram, such as figure 1 As shown, based on the setting of the wrist-arm installation robot, the wrist-arm installation robot includes a road flat car traveling along the direction of the track, a lifting mechanism fixed on the road flat car for lifting operation, and the lifting mechanism adopts a lifting shaft and a rotatable The combination of the lifting mechanical arm is fixed on the road flat car for the sliding rail of the lifting mechanism to slide along the track direction, and the wrist arm grabbing mechanism set at the front end of the lifting mechanism is fixed on the road flat car for operation. The operator installs the operating platform of the wrist arm;

[0039] The wrist arm mounted robot control system includes a main control module for controlling the drive module and then the drive mechanism, a touch screen for operating the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com