Edge banding equipment for rice straw decoration plate production

A technology of rice straw and edge banding equipment, which is applied to household components, wood processing appliances, etc., and can solve problems such as polluted air, thin straw boards, and inclined falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

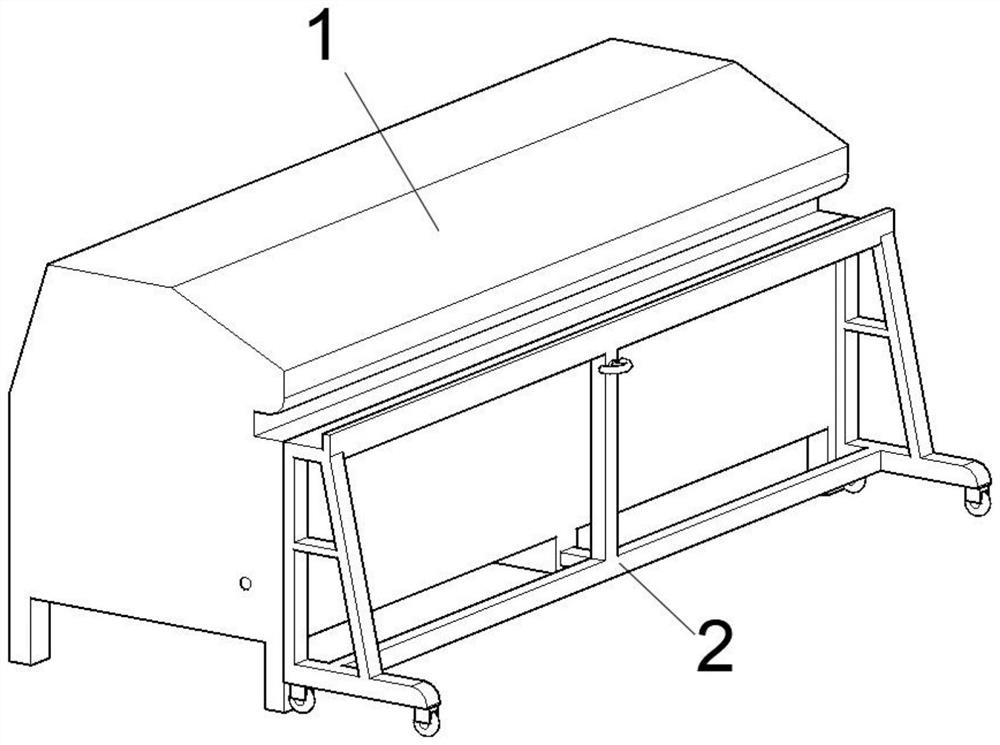

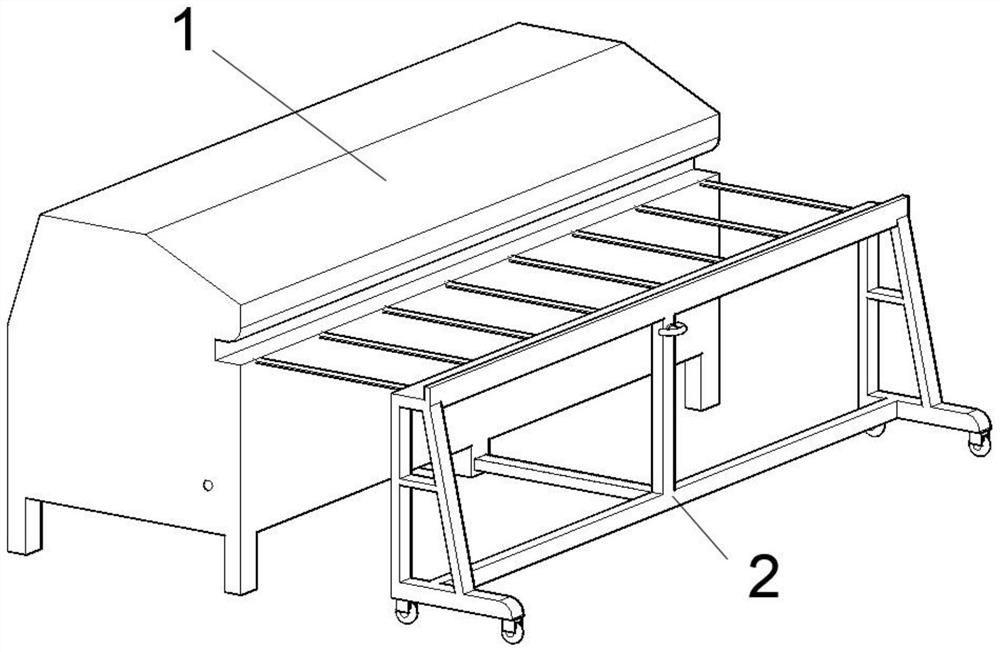

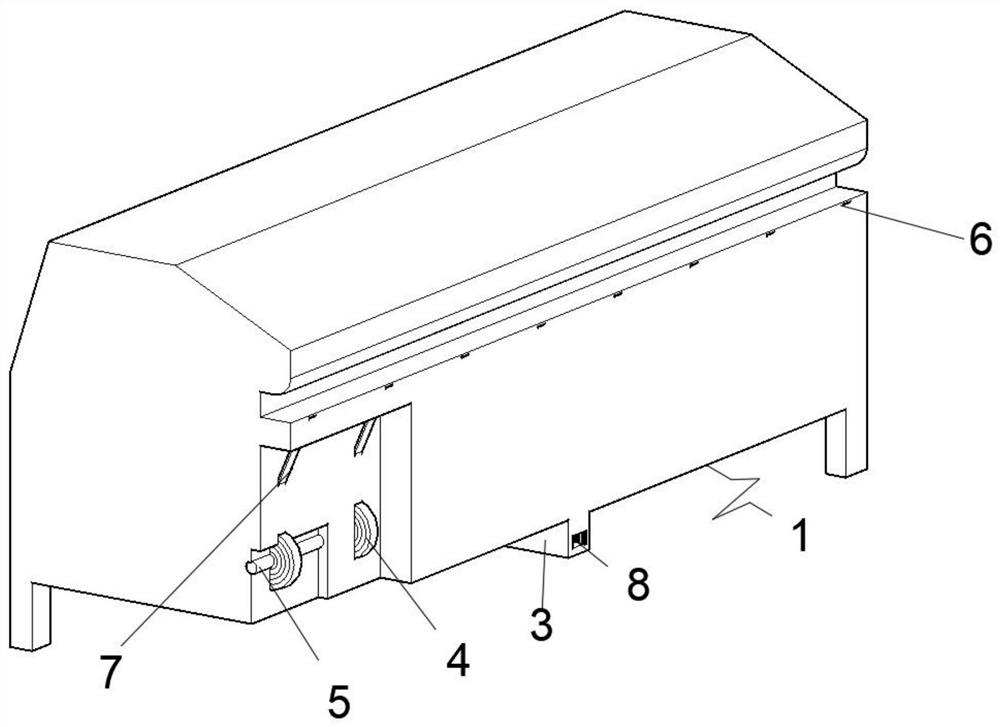

[0031]Seefigure 1 One embodiment of the present invention is: a binder device for rice straw decoration board, including edge-banding machine 1 and support device 2, characterized in that the support device 2 slides in the side surface of the edge of the edge, The inner bottom end of the edge of the edge of the edge is rotated and the shaft 5 is attached, and the outer surface of the rotating shaft 5 is uniformly fixedly coupled with the coil spring 4, and the outer surface of the reel spring 4 is wrapped therewith having a rope belt 7, and the bottom surface of the edge of the edge of the edge is fixed. Bit sleeve 3, the side center of the edge of the edge of the edge is uniformly opened, and the upper surface of the limit sleeve 3 is opened with a pore structure, and a fixing device is connected in the pore structure, the pore structure is a tooth groove 8. One end surface center of the limit sleeve 3 is opened with a tooth groove 8, and the inside of the support device 2 is fixed...

Embodiment 2

[0034]On the basis of Example 1, ifFigure 6-7As shown, the hole body structure is a threaded hole 22, and the upper surface center of the bottom surface center limit sleeve 3 of the edge of the edge is opened, and the fixed structure is a bottom side center spiral connection of the bottom side center of the threaded rod 24 support device 2. The rod 24, one end surface of the threaded rod 24 welded to have a turntable 23.

[0035]In the present embodiment, the rotating plate 23 can be pulled by the rotary turntable 23 in the inside of the threaded hole 22, and the support device 2 can be driven back and forth in lateral direction of the edge of the edge of the edge, so that the support device 2 can be different. The sides of the sized straw plate functions, and can adjust the position of the support device 2 to ensure that the support device 2 is stabilized as the support of the straw plate side.

[0036]Working principle: The user can adjust the position of the support device 2 by adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com