Ship shafting intermediate bearing base mounting and adjusting device

An intermediate bearing, installation and adjustment technology, applied to ships and other directions, can solve the problems of quality risk, reduce work efficiency, waste man-hours, etc., and achieve the effect of reducing re-grinding and painting work, simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

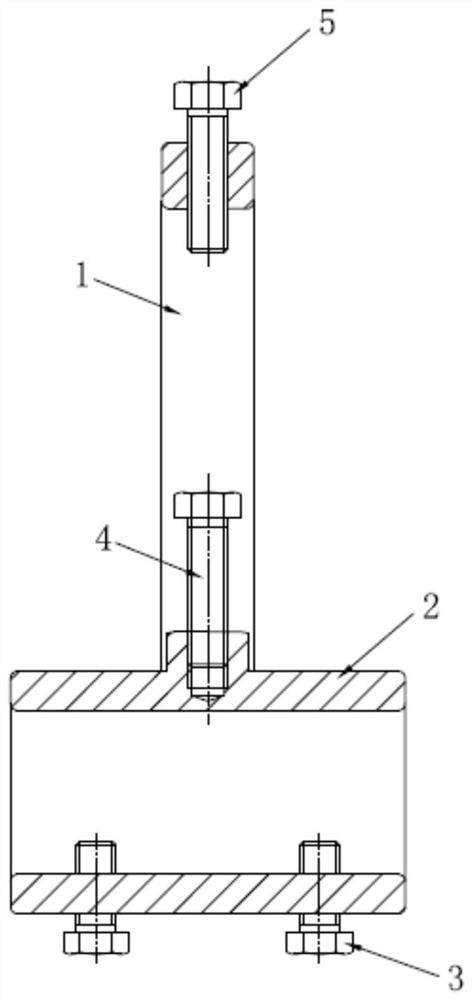

[0028] This embodiment provides an installation and adjustment device for the base of the intermediate bearing of the ship's shafting system, which is suitable for height adjustment between the base of the intermediate bearing of the main engine's shafting system in the shipbuilding field and the base. The material produced by the bearing adjustment method cannot be recovered and the working hours are wasted, and the problem of damage to the bearing base 9 caused by the heat generated in the welding process is avoided, and the work efficiency is improved.

[0029] The installation and adjustment device of this embodiment is composed of two parts: a fixed area and an adjustment area. The fixed area is composed of a fixed base 2 and a fixed bolt 3 . The fixed base 2 is welded by three steel plates. The fixed base 2 is provided with a fixed slot along one side thereof. The width of the fixed slot is greater than the thickness of the bearing base 8. The lower plate of the fixed bas...

Embodiment 2

[0032] This embodiment provides a method for installing and adjusting the base of the intermediate bearing of the shafting of a ship. The installation and adjustment device for the base 9 of the intermediate bearing of the shafting of a ship in Embodiment 1 is used, and the steps are as follows:

[0033] Step 1. According to the thickness of the bearing base 8 and the distance between the bearing base 9 and the bearing base 8, determine the lengths of the fixing bolt 3, the jacking adjustment bolt 4, and the pressing down adjustment bolt 5;

[0034] Step 2. Adjust the distance between the fixing bolt 3 and the upper plate of the fixed base 2 to be slightly larger than the thickness of the bearing base 8, and adjust the distance between the jacking adjustment bolt 4 and the lowering adjustment bolt 5 to be slightly larger than the bearing base 9 thicknesses;

[0035] Step 3. Put the installation and adjustment device in place, the jacking adjustment bolt 4 and the down-pressing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap