Meltblown cloth extrusion method

A technology of melt-blown cloth and melt-blown, which is applied in the direction of melt-spinning, non-woven fabrics, textiles and papermaking, etc., which can solve problems such as poor extrusion effect of melt-blown liquid and influence on extrusion efficiency, so as to increase elasticity and reduce Backflow obstruction, effect of increasing the backflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0017] The method for extruding melt-blown cloth includes extruding the melt-blown liquid by using a screw barrel of a melt-blown cloth extruder.

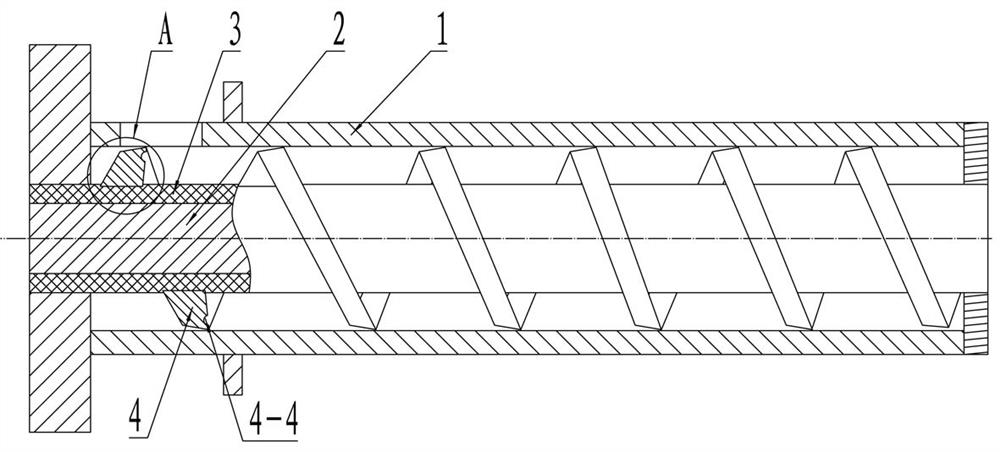

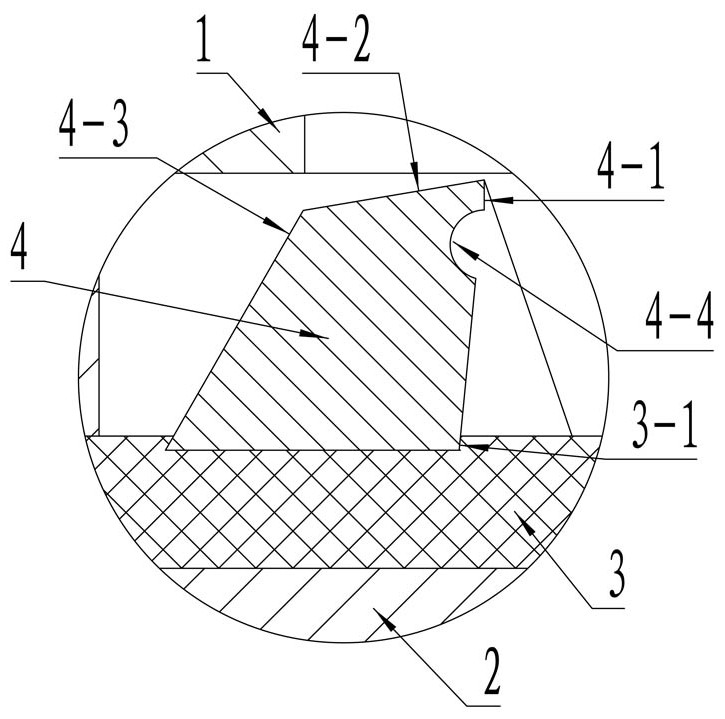

[0018] This melt-blown cloth extruder screw barrel is such as Figure 1 to Figure 2 As shown, it includes a barrel 1 sheathed by a screw, the screw includes a central rotating shaft 2 and a spiral thread segment 4 outside it, a flexible nesting 3 is provided between the outside of the central rotating shaft 2 and the helical thread segment 4, and the flexible nesting 3 is provided There is a helical groove 3-1, and the helical thread segment 4 is connected to the central rotating shaft 2 by embedding the flexible nested helical groove 3-1. A split screw is used, and the central rotating shaft 2 and the helical thread segment 4 are connected by the flexible nesting 3. Connection, using the flexible forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com