Basement working condition low type loader

A low-profile, loader technology, used in earthmovers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve the problems of poor air conditioning, low cab height, etc., to solve the problem of air conditioning layout, improve work comfort, and improve the operation field of vision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

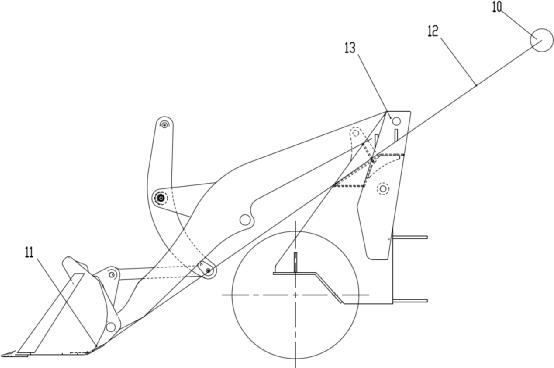

[0031] The present invention will be described below in conjunction with the accompanying drawings and examples.

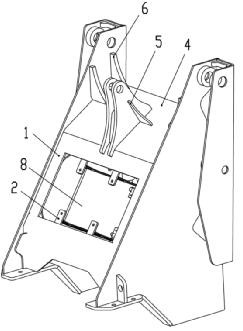

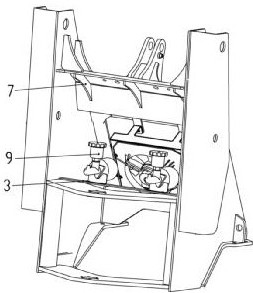

[0032] combine Figure 1 to Figure 3 As shown, a low-slung loader for basement working conditions,

[0033] A rear tilt panel I1 and a rear tilt panel II4 are installed between the two vertical plates of the front vehicle frame 13 . The reclining panel II4 is located on the rear and upper side of the reclining panel I1, and the inclination angle of the reclining panel II4 relative to the front frame 13 is greater than the inclination angle of the reclining panel I1 relative to the front frame 13. The tipping lug seat is fixed in the middle of the upper surface of the rear tilting panel II4, and the small rib plate 5 of the tipping bucket ear seat is welded between the two sides of the tipping bucket ear seat and the upper surface of the rear tilting panel II4, and the side of the small rib plate 5 of the tipping bucket ear seat is arc-shaped . A stiffener plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com