A Self-Resetting Type Stiffness Adaptive Control Assembled Beam-Column Joint

A technology of adaptive control and beam-column joints, applied in building types, protected buildings/shelters, buildings, etc., can solve the problems of difficult to achieve rapid recovery of building functions, weak self-resetting ability of structures, and difficult repairs, etc. Achieve the effects of easy construction quality assurance, easy construction quality assurance, and fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

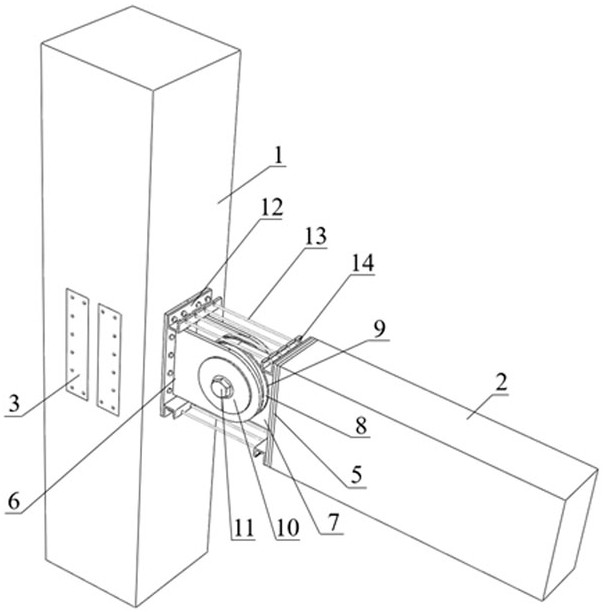

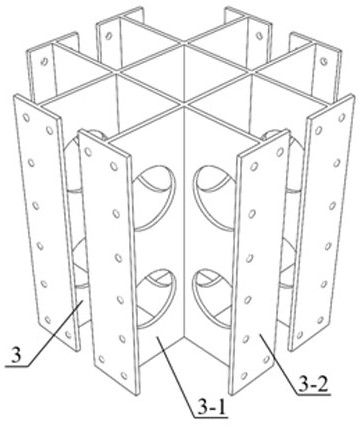

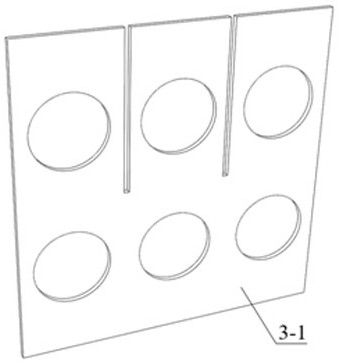

[0016] like Figure 1~Figure 16 As shown, the present invention is a self-resetting stiffness self-adaptive control assembled beam-column node, including a prefabricated column 1, a prefabricated beam 2, a column T-shaped connecting plate 6, a beam T-shaped connecting plate 7, a saddle-shaped circular plate 8, The pin shaft 11, the U-shaped slot 12, the high elastic member 13, the web part 3-1 of the well-shaped steel cylinder, and the flange part 3-2 of the well-shaped steel cylinder are in the node core area of the prefabricated column 1 Pre-embed the well-shaped steel cylinder 3, the well-shaped steel cylinder 3 is connected with the first vertical plate 6-1 of the two parallel column T-shaped connecting plates through bolts, and the anchoring section steel is embedded at the end of the prefabricated beam 2 4. The anchoring section steel 4 is welded and fixedly connected with the beam end plate 5, and the beam end plate 5 is connected with the second vertical plate 7-1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com