Method for segmentally isolating drill hole for water pressurizing, pressure measuring and water pumping

A pressure measurement and separation device technology, applied in the direction of drilling equipment and methods, measurement, drilling equipment, etc., can solve the problems of difficult cleaning, limited drilling space, inconvenient pipeline lowering, etc., to achieve convenient operation and simple principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

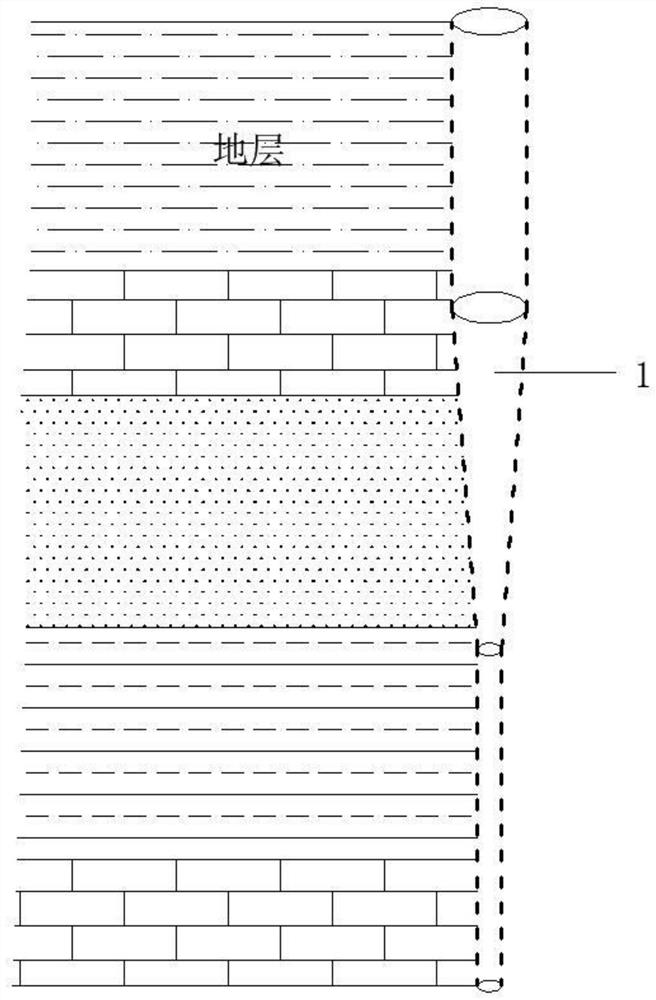

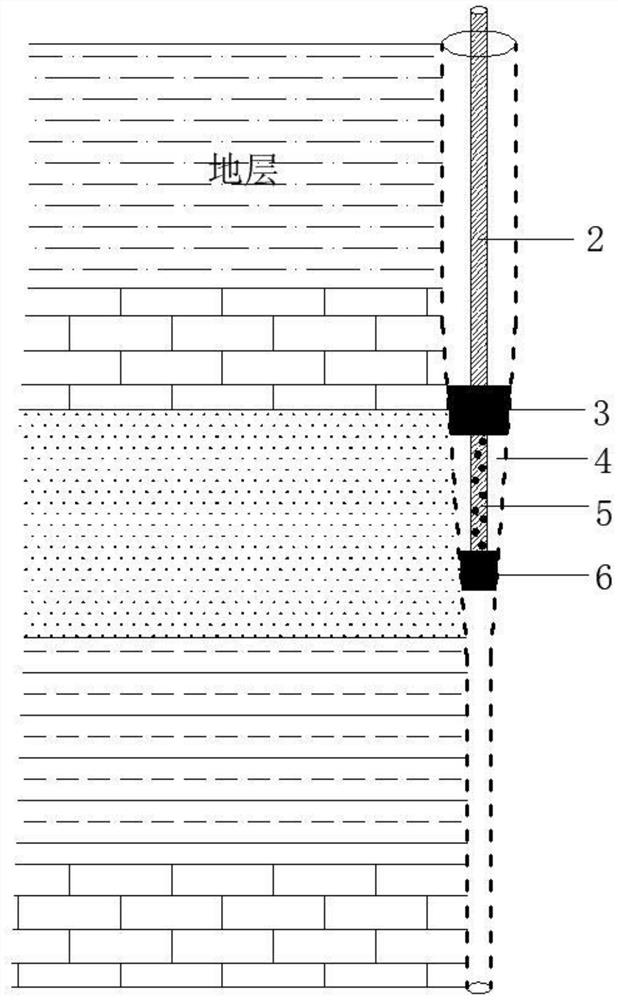

[0026] Such as figure 1 , figure 2 As shown, a method for segmental isolation of water pressure, pressure measurement, and pumping drilling, specifically includes the following steps:

[0027] 1) According to the position requirements of the test section 1, construct the corresponding drilling holes of the test section 1 into a rounded table shape, and construct the other non-test section 1 into a conventional cylindrical shape; the specific method is: set the test section 1 at a depth of H 1 to H 2 , set the hole opening position to point o, then set the hole depth from o to H 1 The section is constructed into a cylindrical shape with conventional drilling equipment, and the hole diameter is d 1 , into the hole depth H 1 When changing to the total length H 2 -H 1 Drilling tool for conical hole construction, the shape of the drilling tool is consistent with the shape of the final hole, and the outer diameter of the bottom of the drilling tool is d 2 , top outer longitu...

Embodiment 2

[0034] In step 3), the drill pipe 2 is used to replace the floral tube 5. The drill pipe 2 passes through the upper partition device 3 and is fixed on the lower partition device 6. The upper partition device 3 is also fixed with the drill pipe 2, and the drill rod 2 is located in the upper partition device 3. Part of the outer wall between the lower partition device 6 has a through hole communicating with the inner space, and other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com