Pressure-relief-reinforcement cooperative maintenance method for roadway under boundary coal pillar

A technology for boundary coal pillars and roadways, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as large deformation of surrounding rock of roadways, and achieve the effects of convenient operation, guaranteed stability and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

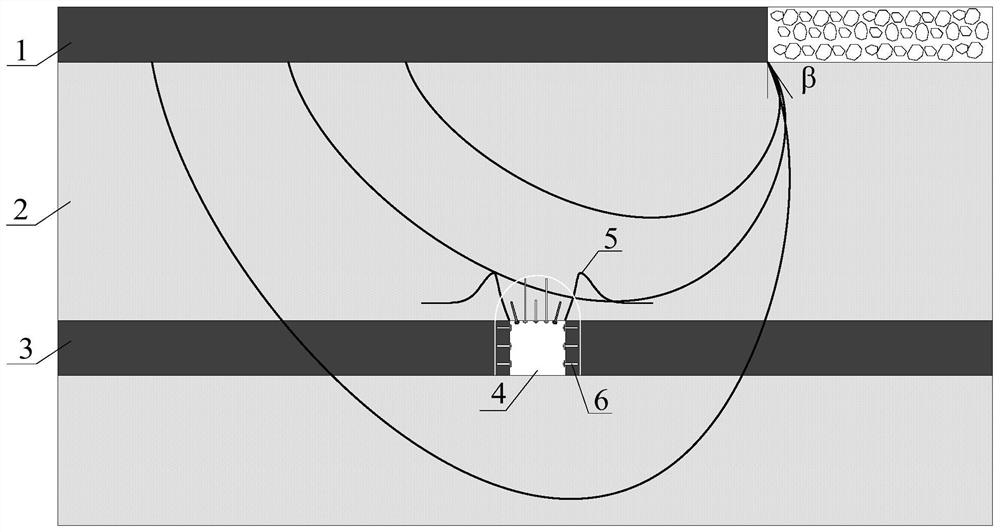

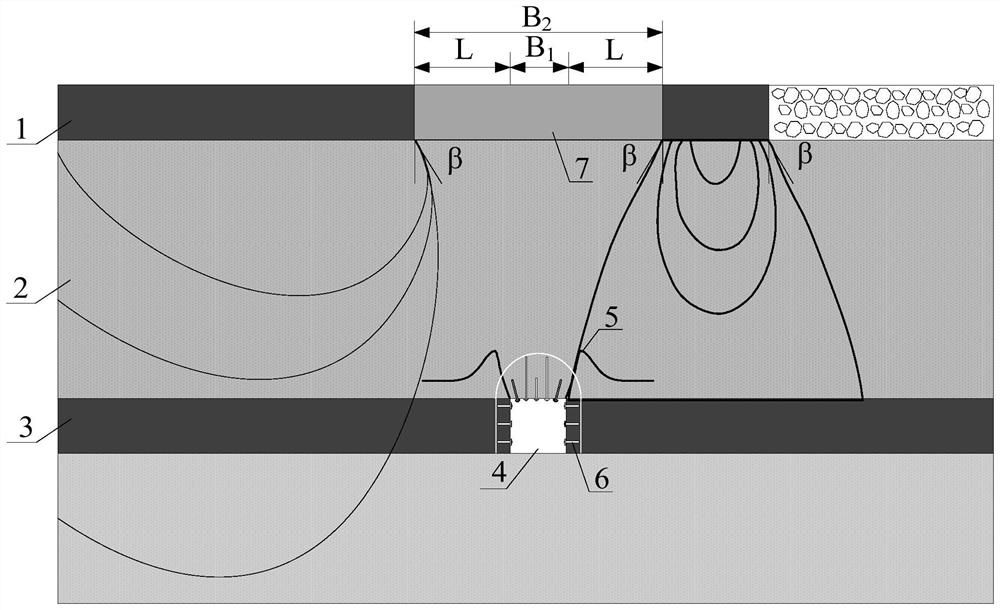

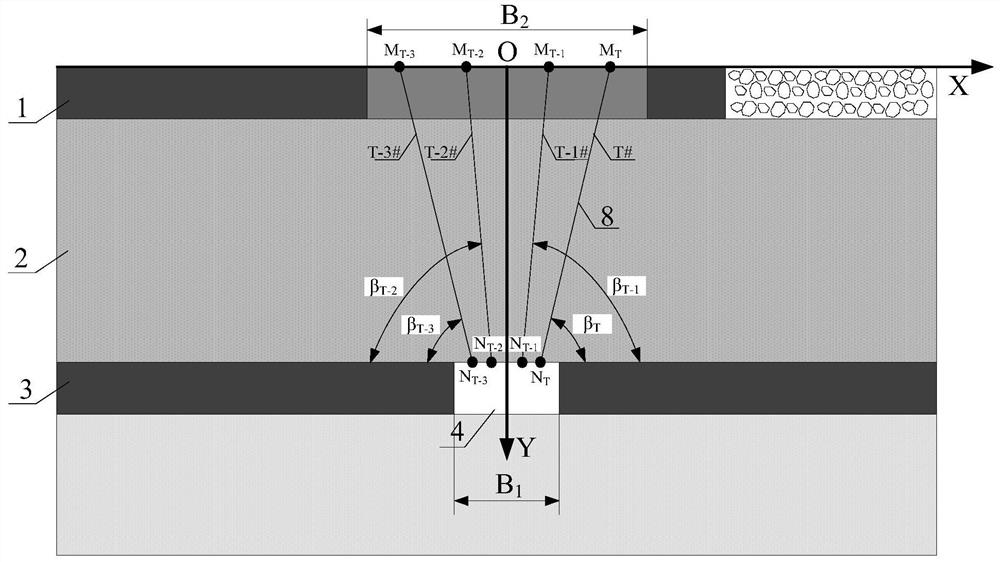

Method used

Image

Examples

Embodiment 2

[0117] On the basis of Embodiment 1, taking a certain coal mine as an example, the pressure relief-reinforcement coordinated maintenance method of the roadway under the boundary coal pillar is described. The mine is currently mined in close-distance coal seams. After the upper coal seam is mined, there is an overlying boundary coal pillar with a width of 80m and an upper coal seam thickness of H 3 The average is 6m, and the compressive strength is 30MPa. The average thickness of the lower coal seam is 4m, and the compressive strength is 30MPa. A mining roadway (that is, the roadway below the overlying boundary coal pillar) is arranged under the overlying boundary coal pillar in the lower coal seam. The height of the roadway below the overlying boundary coal pillar is H 2 4m, width B 1 is 5m, the roof is supported by anchors + anchor cables, and the side is supported by anchors, where the specifications of the anchors are The specification of the anchor cable is Upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com