Weighing method-based gradient deflation type SF6 gas chamber volume measurement method

A measurement method and a weighing method, which are used in volume measurement instruments/methods, container filling methods, container discharge methods, etc., and can solve problems such as difficult pressure values, excessive gas release, and prone to measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

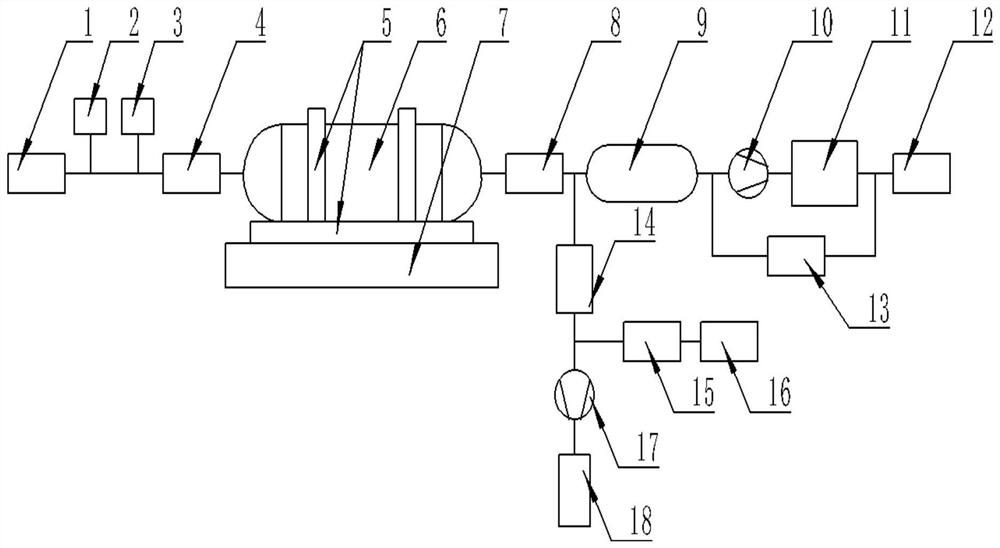

[0068] Such as figure 1 As shown, the deflation measurement device includes: deflation interface (1), pressure sensor (2), temperature sensor (3), flow regulating valve (4), fixed frame (5), deflation tank (6), weighing Device (7), first solenoid valve (8), buffer tank (9), compressor (10), refrigeration unit (11), waste gas outlet (12), second solenoid valve (13), third solenoid valve ( 14), the fourth electromagnetic valve (15), vacuum gauge (16), vacuum pump (17), vacuum exhaust port (18); described deflation interface (1), pressure sensor (2), temperature sensor ( 3), flow regulating valve (4), fixed frame (5), air release tank (6), weighing device (7), first solenoid valve (8), buffer tank (9), compressor (10), The refrigeration unit (11) and the exhaust gas outlet (12) are sequentially sealed and connected in series; one end of the second electromagnetic valve (13) is sealed and connected between the buffer tank (9) and the compressor (10), and the second electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com