Gradient inflatable SF6 gas chamber volume measurement method based on constant volume method

A determination method and technology of constant volume method, which are applied in container filling method, container discharge method, volume measuring instrument/method, etc., can solve problems such as inflation overpressure, difficult pressure value, quality deviation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

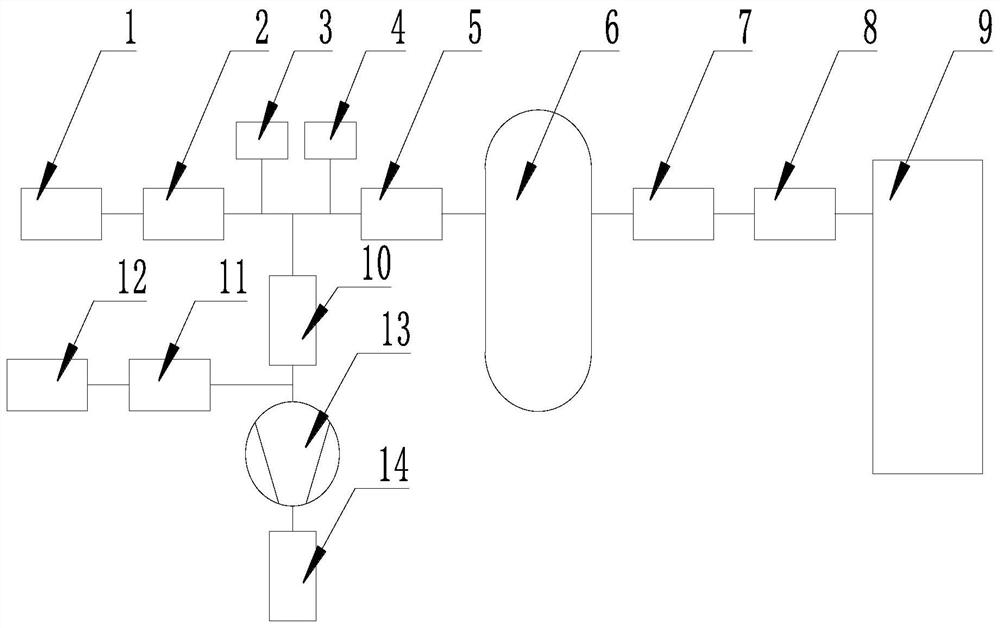

[0089] Such as figure 1 As shown, the inflation measurement device includes: inflation interface 1, first solenoid valve 2, pressure sensor 3, temperature sensor 4, flow regulating valve 5, constant volume inflation tank 6, second solenoid valve 7, pressure reducing valve 8, SF 6 Steel cylinder 9, third electromagnetic valve 10, fourth electromagnetic valve 11, vacuum gauge 12, vacuum pump 13, exhaust port 14.

[0090] Inflatable interface 1, first solenoid valve 2, pressure sensor 3, temperature sensor 4, flow regulating valve 5, constant volume inflatable tank 6, second solenoid valve 7, pressure reducing valve 8, SF 6 The steel cylinder 9 is sealed and connected in sequence from the beginning to the end; a gas path is sealed and connected between the first electromagnetic valve 2 and the flow regulating valve 5, and connected in turn to the third electromagnetic valve 10, vacuum pump 13, and exhaust port 14; the vacuum gauge 12 passes through the fourth electromagnetic val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com