Method for measuring length of interference area of transonic wind tunnel support system

A measurement method and transonic speed technology, applied in the field of transonic wind tunnel test, can solve the problem of inability to accurately determine the interference size of transonic wind tunnel test data, etc., and achieve the effect of simple and reliable structure, convenient operation method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

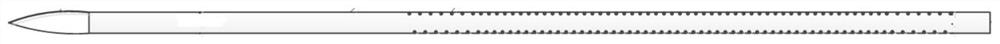

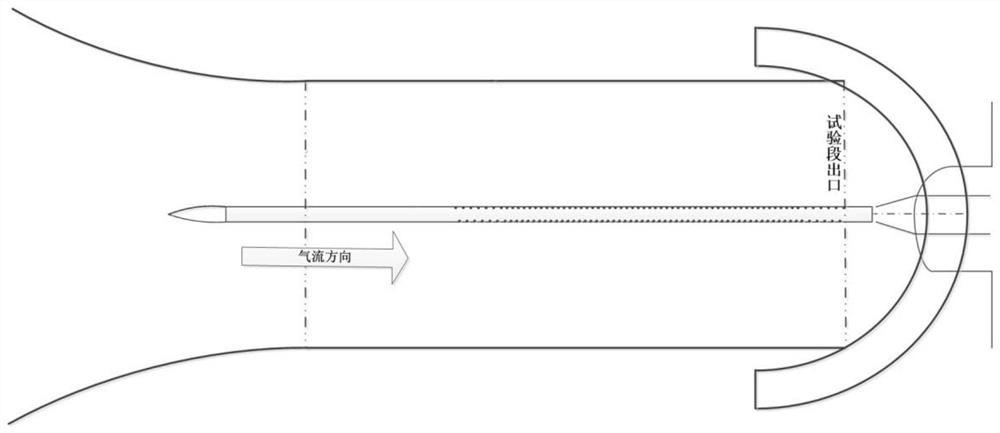

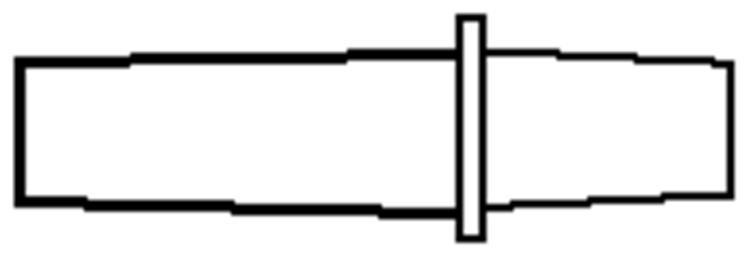

[0024] The overall length of the axial static pressure detection tube in this embodiment is 1.8m, L:D=8:1, see figure 2 , the supporting mechanism is as image 3 Straight header shown.

[0025] The method for measuring the length of the interference zone of the transonic wind tunnel support system in this embodiment includes the following steps:

[0026] a. Install the axial detection bent frame on the middle bracket of the transonic wind tunnel, start the transonic wind tunnel at the Mach number Ma=0.3, move the axial detection bent frame according to the preset path, change the measurement position until the measurement Complete, close the transonic wind tunnel, obtain the Mach number distribution of the core flow field of the transonic wind tunnel with Mach number 0.3 after data processing, and obtain the flow calibration results of the transonic wind tunnel;

[0027] b. Remove the axial detection bent frame, install the direct head, and install the axial static pressure...

Embodiment 2

[0034] The implementation of this embodiment is basically the same as that of Embodiment 1, the main difference is that the supporting mechanism is as Figure 4 The length of the interference zone obtained for the dual-shaft system joint shown is shown in Table 1.

Embodiment 3

[0036] The implementation of this embodiment is basically the same as that of Embodiment 1, the main difference is that the supporting mechanism is as Figure 5 The length of the interference zone obtained for the optimized dual-axis joint shown in Table 1.

[0037] Table 1 Test results of interference zone length for different support systems

[0038] Ma 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0.95 1.0 Flow Field Calibration 1.20 1.45 1.60 1.60 1.60 1.60 1.60 1.60 1.30 straight head 1.58 1.64 1.73 1.76 1.76 1.79 1.94 1.94 1.79 Dual Shaft System Connector 1.73 1.85 1.94 2.00 2.21 2.21 2.21 2.15 1.94 Optimized dual shaft system joint 1.64 1.73 1.79 1.85 1.85 1.94 2.00 2.00 1.79

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com