Accident expansion prevention control method and system for multi-strand square billet casting machine

A technology of sudden accident and control method, which is applied in multi-strand billet continuous casting production to prevent sudden accident expansion, equipment and personal safety. , personnel injury equipment and other issues, to achieve the effect of improving accident emergency response capabilities, standardizing accident emergency response procedures, and protecting personal and equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

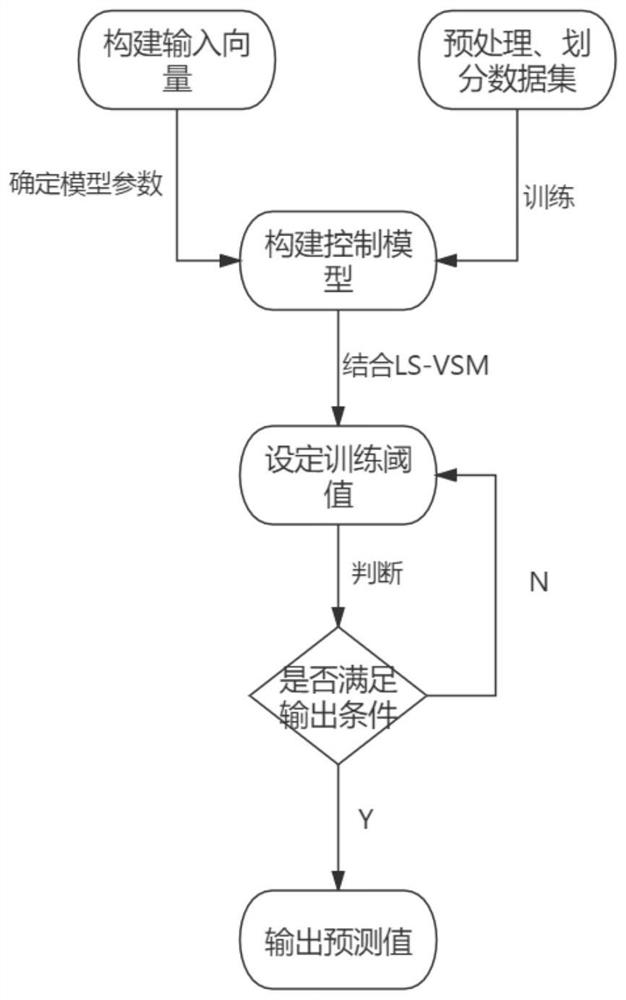

[0040] refer to figure 1 and figure 2 , which is the first embodiment of the present invention, provides a multi-strand billet caster anti-emergency expansion control method, which is characterized in that: comprising,

[0041] S1: Construct the input vector based on the least squares support vector machine. What needs to be explained is:

[0042] The time series strategy is a set of one-dimensional observations. When combined with the least squares support vector machine, phase space reconstruction is required. The construction of the input vector includes,

[0043] X(k)=[x(k), x(k-τ), ..., x(k-(D-1)τ)]

[0044] Among them, D is the embedding dimension of phase space reconstruction, τ is the delay time of phase space reconstruction, and X(k) is the input-output vector pair.

[0045] S2: Preprocess the collected sample data, divide the data set, and confirm the model parameters of the input vector. What needs to be explained in this step is:

[0046] Preprocessing inclu...

Embodiment 2

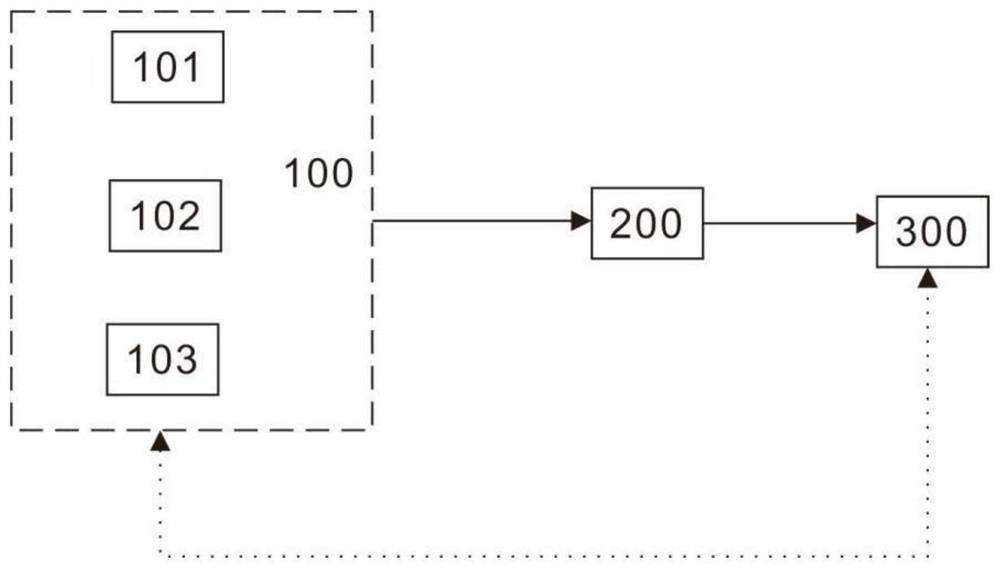

[0066] refer to Figure 3 ~ Figure 7 , is the second embodiment of the present invention. This embodiment is different from the first embodiment in that it provides a multi-strand billet caster anti-emergency expansion control system, including:

[0067] refer to Figure 4 , Figure 5 and Figure 7 , the hydraulic module 100 is used to meet the one-button independent operation in the event of an accident, which includes a hydraulic station outlet oil pipe 101, a hydraulic cylinder 102 and a blind plate 103, and the hydraulic station outlet oil pipe 101 moves with the tundish car to provide power for the hydraulic cylinder 102 , each casting flow is independently equipped with hydraulic cylinder equipment and can be operated independently, and the hydraulic cylinder 102 is used in conjunction with the blind plate 103; the hydraulic module 100 is also equipped with a one-button button, which can control the hydraulic cylinder equipment of each flow at the same time. With one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com