Metal-loaded dolomite catalyst for preparing ethanol by glycerol dehydration and preparation method thereof

A technology for supporting metal and dolomite, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of explosion and high cost, and achieve simple operation method, Save time, cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

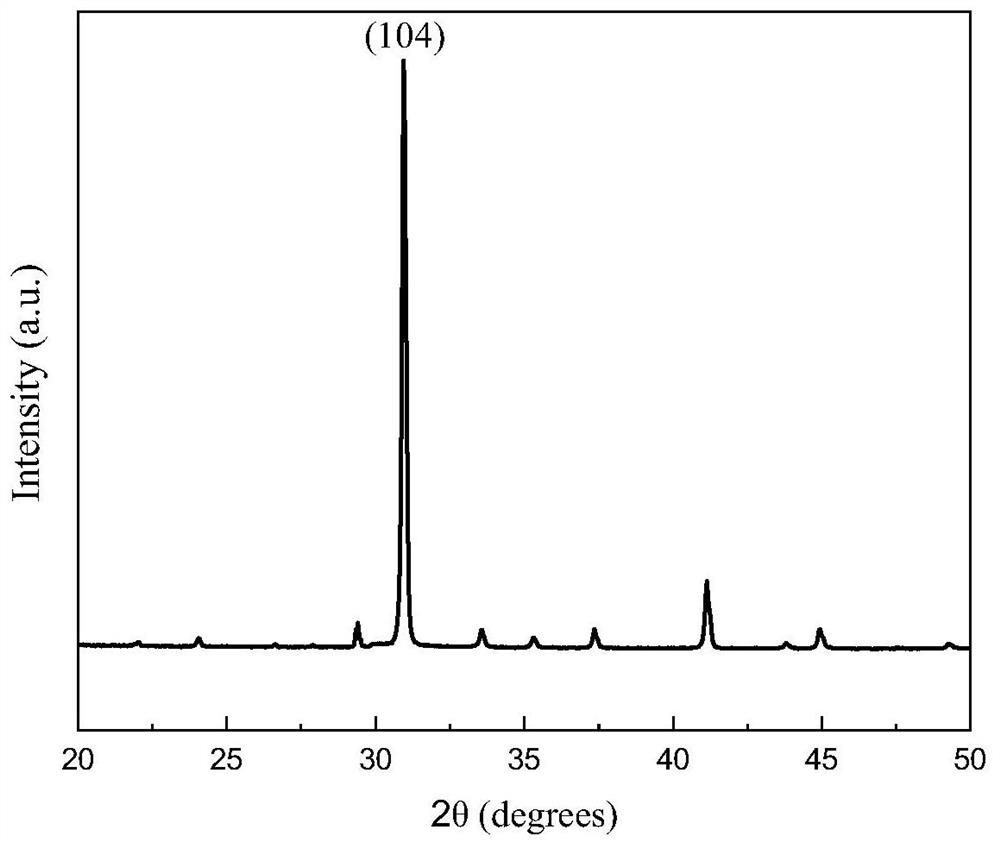

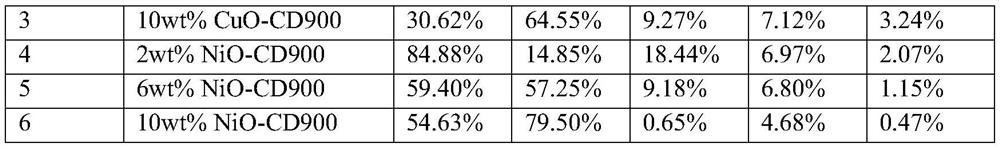

Embodiment 1

[0034] Weigh 10g of natural dolomite, grind it to 60-80 mesh, wash with ethanol, then put it in an oven at 80°C for 4h to dry it, put the dried dolomite particles into the muffle furnace, Calcined at 900° C. for 4 hours under a heating program of 5° C. / min to obtain a calcined dolomite catalyst. Weigh 0.204g of copper nitrate and place it in a 50ml beaker, add 10ml of deionized water, stir it with a glass rod to dissolve it completely, then weigh 10g of calcined dolomite at 900°C as a carrier, add it to the above solution, mix Put it on a magnetic stirrer and stir for 4 hours at a stirring speed of 300r / min. After stirring, impregnate for 24 hours, put it in an oven at 80°C for 12 hours at a constant temperature, and finally put the dried sample into a muffle furnace for calcination at 900°C. The heating program was 10°C / min and calcined for 4 hours to obtain a 2wt.% copper catalyst supported on calcined dolomite, which was recorded as 2wt% CuO-CD900. The catalytic activity is...

Embodiment 2

[0036] Weigh 10g of natural dolomite, grind it to 60-80 mesh, wash with ethanol, then put it in an oven at 80°C for 4h to dry it, put the dried dolomite particles into the muffle furnace, Calcined at 900° C. for 4 hours under a heating program of 5° C. / min to obtain a calcined dolomite catalyst. Weigh 0.638g of copper nitrate and place it in a 50ml beaker, add 10ml of deionized water, stir it with a glass rod to dissolve it completely, then weigh 10g of calcined dolomite at 900°C as a carrier, add it to the above solution, and mix Put it on a magnetic stirrer and stir for 4 hours at a stirring speed of 300r / min. After stirring, impregnate for 24 hours, put it in an oven at 80°C for 12 hours at a constant temperature, and finally put the dried sample into a muffle furnace for calcination at 900°C. The heating program was 10°C / min, and calcined for 4 hours to obtain a 6wt.% copper catalyst supported on calcined dolomite, denoted as 6wt% CuO-CD900. The catalytic activity is shown...

Embodiment 3

[0038] Weigh 10g of natural dolomite, grind it to 60-80 mesh, wash with ethanol, then put it in an oven at 80°C for 4h to dry it, put the dried dolomite particles into the muffle furnace, Calcined at 900° C. for 4 hours under a heating program of 5° C. / min to obtain a calcined dolomite catalyst. Weigh 1.111g of copper nitrate and place it in a 50ml beaker, add 10ml of deionized water, stir it with a glass rod to dissolve it completely, then weigh 10g of calcined dolomite at 900°C as a carrier, add it to the above solution, mix Put it on a magnetic stirrer and stir for 4 hours at a stirring speed of 300r / min. After stirring, impregnate for 24 hours, put it in an oven at 80°C for 12 hours at a constant temperature, and finally put the dried sample into a muffle furnace for calcination at 900°C. The heating program was 10°C / min and calcined for 4 hours to obtain a 10wt.% copper catalyst supported on calcined dolomite, which was recorded as 10wt% CuO-CD900. The catalytic activity ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap