Self-adjusting fixture for laser chips

A self-adjusting, chip technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of easy deviation of the chip and unstable clamping, so as to improve the processing efficiency and accuracy, reduce the difficulty of processing and testing, and smooth the thrust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

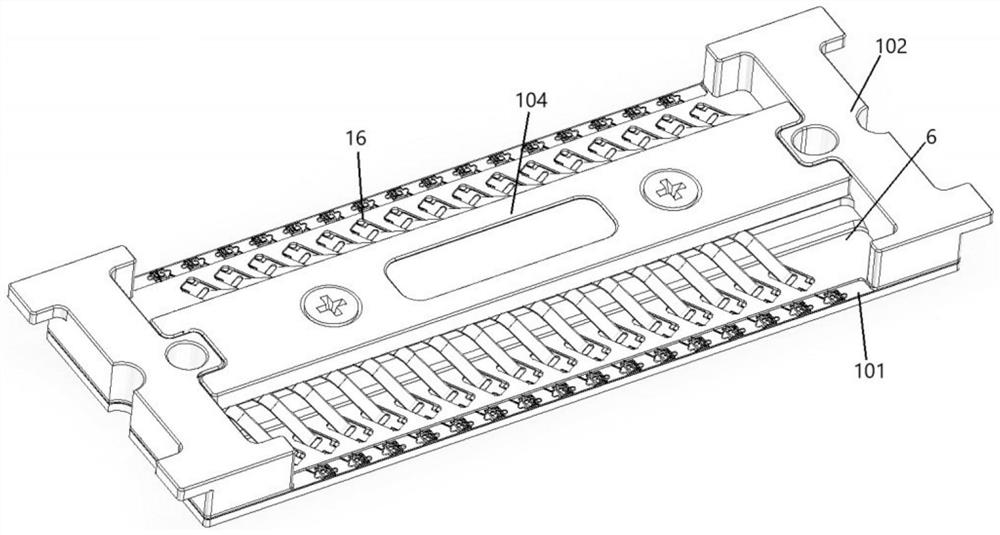

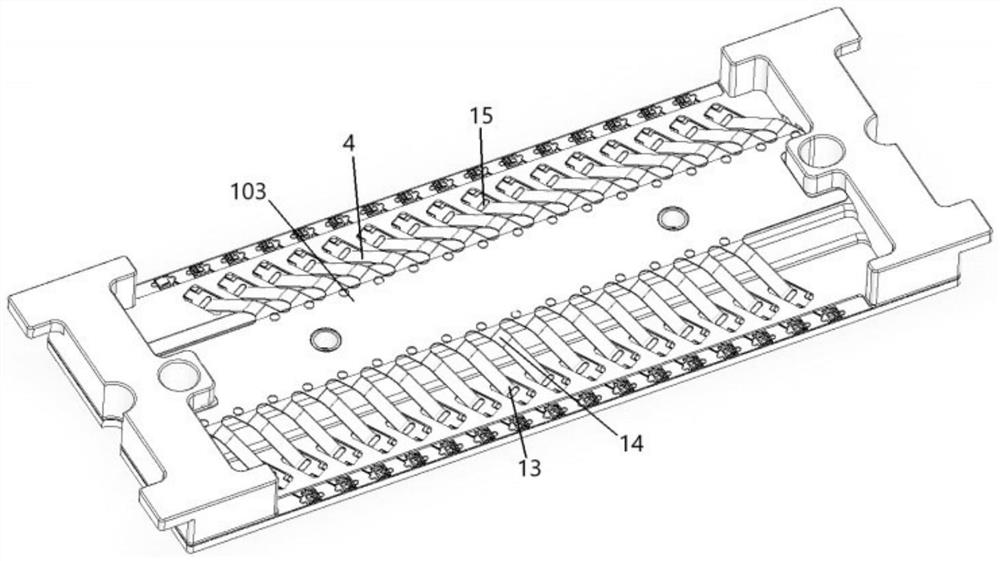

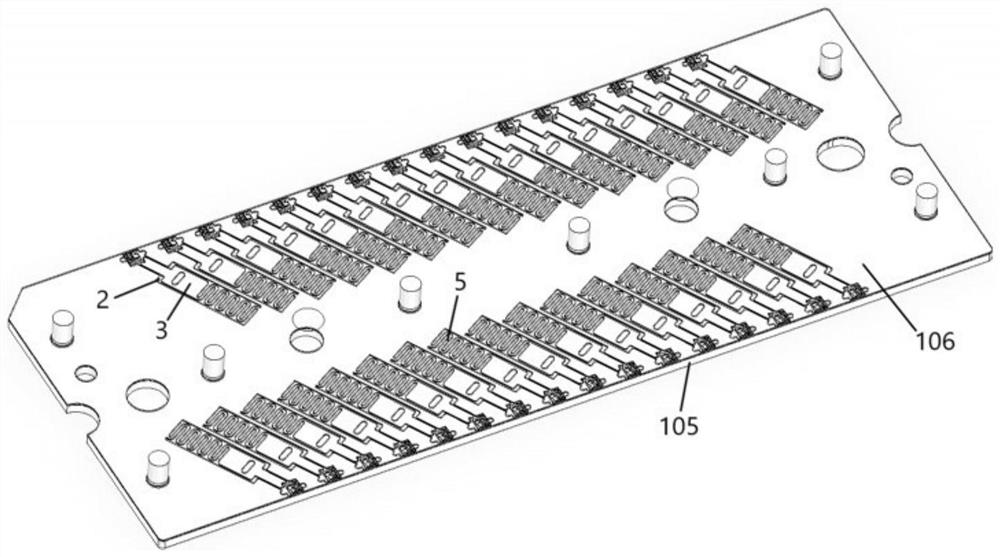

[0025] Example 1: A self-adjusting fixture for laser chips, refer to the attached Figures 1~4 , including a positioning slot 1 and a bar-shaped slot 2 opened on the top surface of the base 101, the positioning slot 1 is communicated with the bar-shaped slot 2 and is used for placing chips, and a positioning plate 3 is movably installed in the bar-shaped slot 2. This positioning The front end of the plate 3 is provided with a right-angle positioning notch 12, the positioning groove 1 has a positioning right-angle 11, the two sides of the right-angle positioning notch 12 are in extrusion contact with the adjacent two sides of the chip, and the two sides of the positioning right angle 11 are in contact with the other two sides of the chip. touch;

[0026] The base 101 is provided with a strip block 102, a spring plate 103 and a pressure plate 104, the strip block 102 is located on the top surface of the base 101, the spring plate 103 is installed on the strip block 102, and the ...

Embodiment 2

[0029] Example 2: A self-adjusting fixture for laser chips, refer to the attached Figures 1~4 , including a positioning slot 1 and a bar-shaped slot 2 opened on the top surface of the base 101, the positioning slot 1 is communicated with the bar-shaped slot 2 and is used for placing chips, and a positioning plate 3 is movably installed in the bar-shaped slot 2. This positioning The front end of the plate 3 is provided with a right-angle positioning notch 12, the positioning groove 1 has a positioning right-angle 11, the two sides of the right-angle positioning notch 12 are in extrusion contact with the adjacent two sides of the chip, and the two sides of the positioning right angle 11 are in contact with the other two sides of the chip. touch;

[0030] The base 101 is provided with a strip block 102, a spring plate 103 and a pressure plate 104, the strip block 102 is located on the top surface of the base 101, the spring plate 103 is installed on the strip block 102, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com