Straw pulverizer

A straw pulverizer and crushing technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of poor pulverization effect, low processing efficiency, waste of resources, etc., and achieve stable feeding, simple structure, quantitative and feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

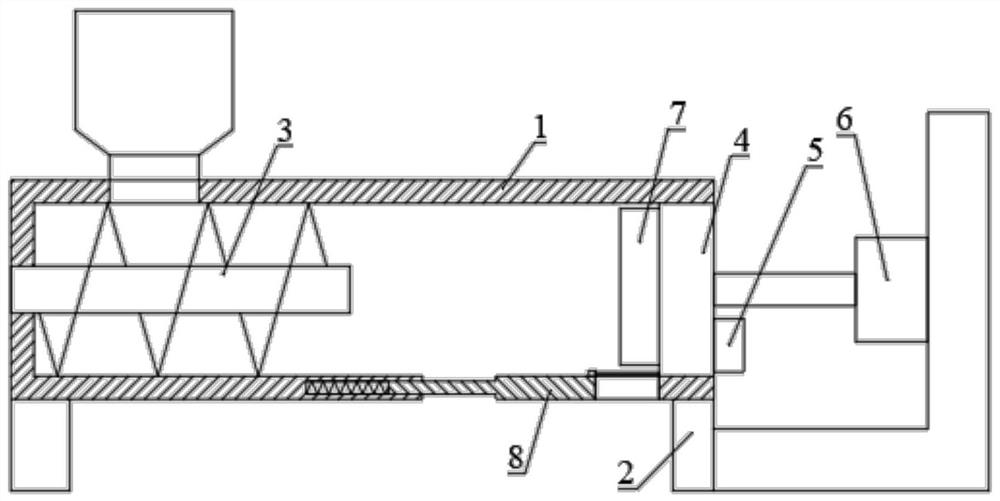

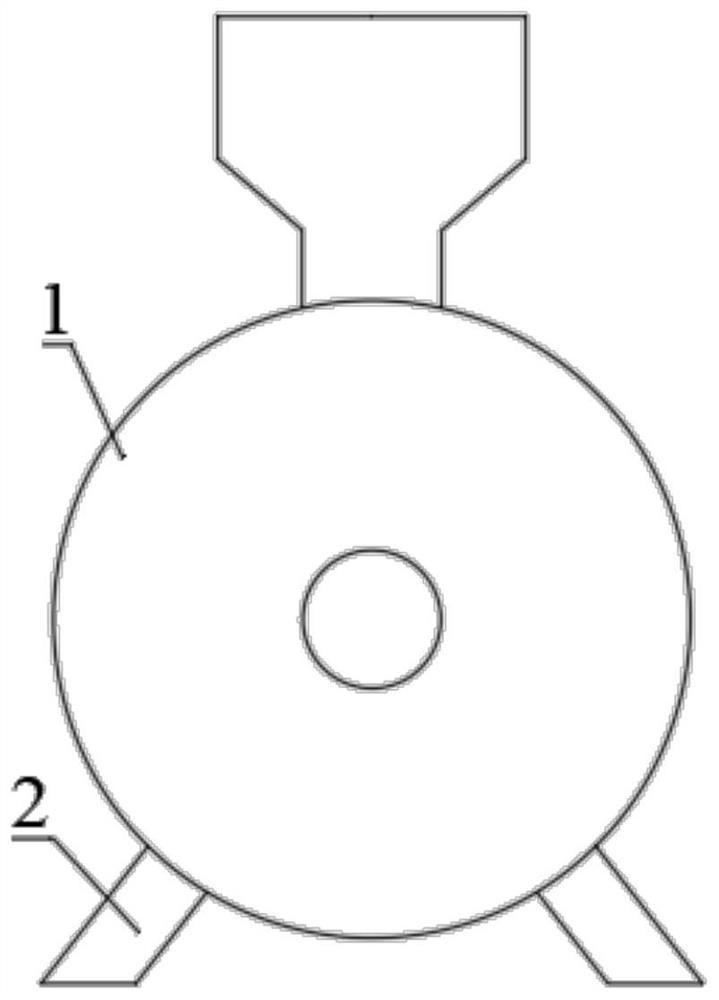

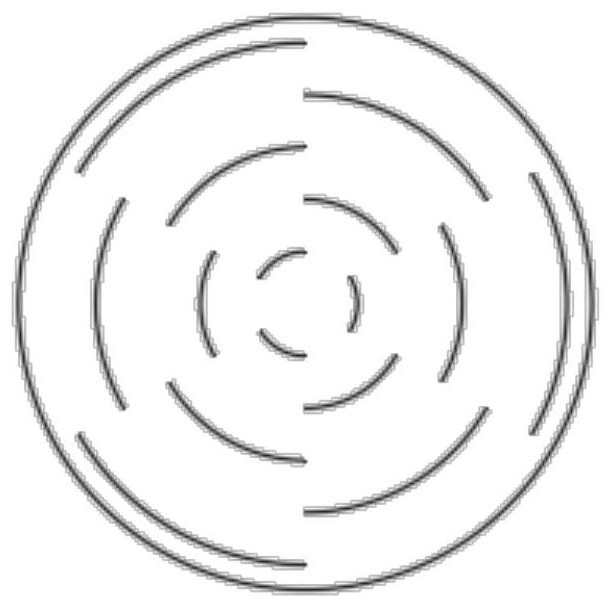

[0013] refer to Figure 1-3 , a straw pulverizer proposed by the present invention includes a base 2, a cylinder 1 is installed on the base 2, a pressurized feeding channel and a crushed material channel are connected in the cylinder 1, and a communication channel is opened on the cylinder 1. The feed port of the pressurized material conveying channel, the screw conveying mechanism 3 is installed in the pressurized material conveying channel, and the crushing material mechanism is installed in the crushing material channel, and the crushing material mechanism includes a turntable 4 arranged coaxially with the cylinder body 1 And the first power assembly that drives the turntable 4 to rotate, a cutter 7 is installed on the side of the turntable 4 adjacent to the pressurized material delivery channel, a gap is opened at the bottom of the cylinder body 1, a groove is opened on the inner wall of the gap, and the movable plate 6 is inserted into the groove. The movable plate 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com