Automatic lens production device

A production device and lens technology, applied in glass molding, application, glass manufacturing equipment, etc., can solve the problems of not being able to eliminate the internal stress of the lens, and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

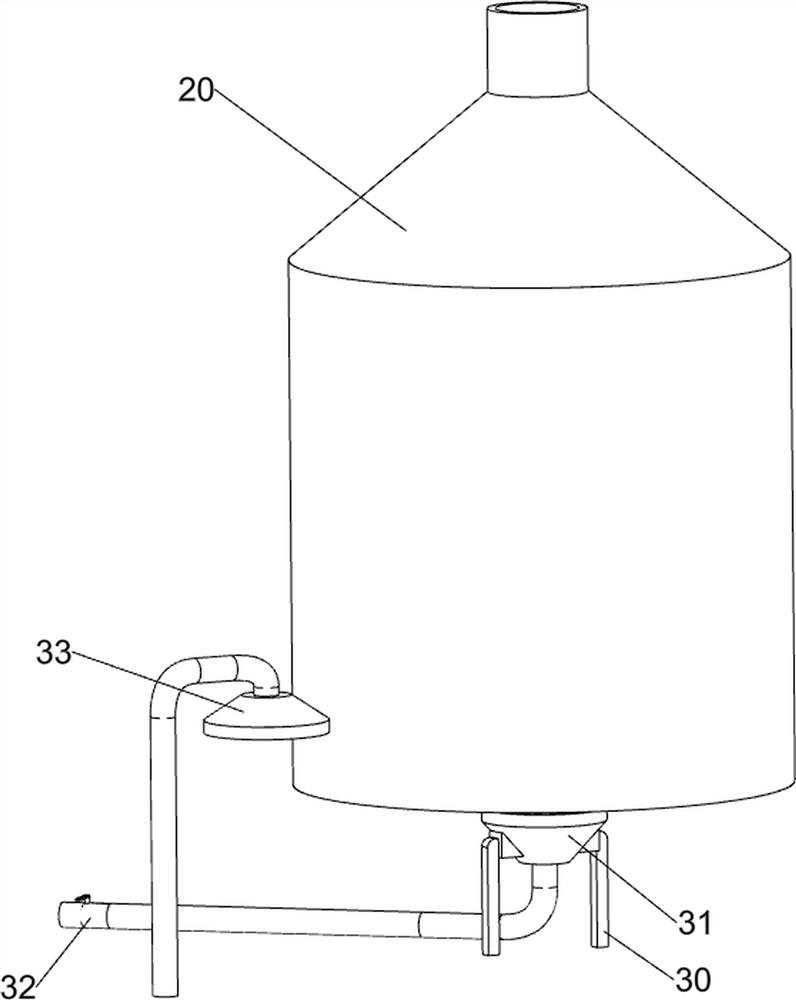

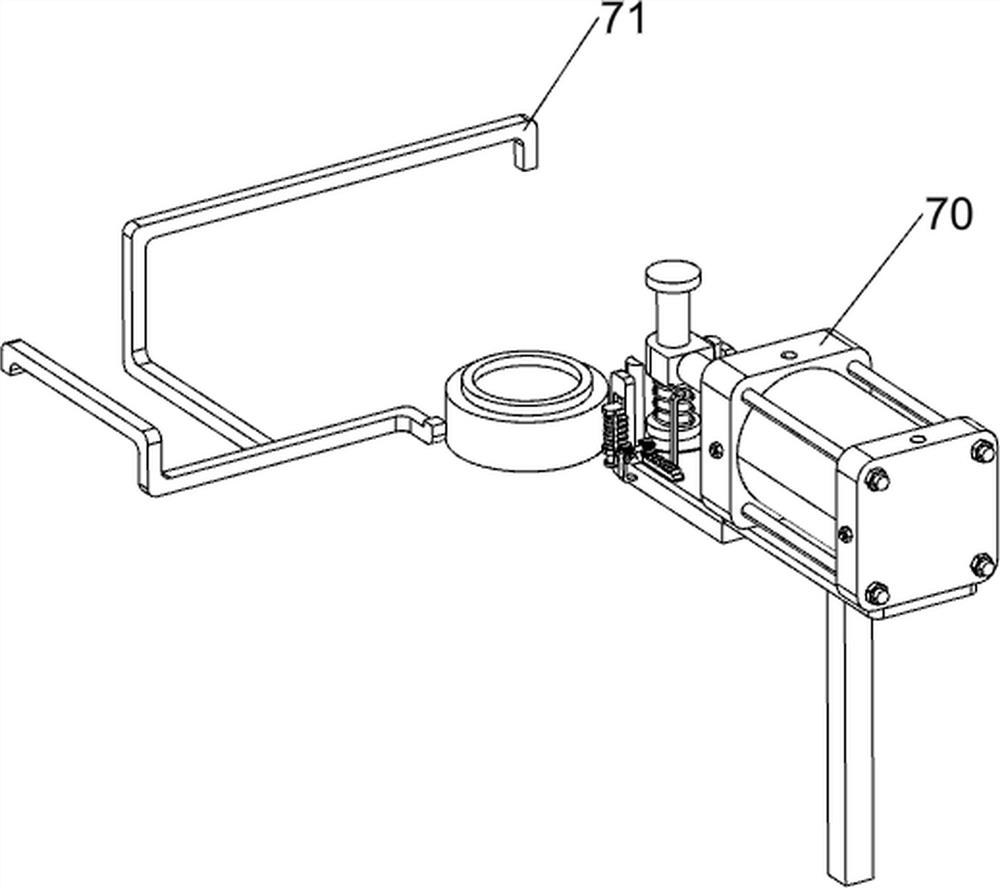

[0036] An automated lens production device, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a base 1 , a discharge mechanism 2 and a heating mechanism 3 , the base 1 is provided with the discharge mechanism 2 , and the base 1 is provided with the heating mechanism 3 .

[0037]When people need to use this device, first people pour the prepared stock solution into the discharge mechanism 2, then start the heating mechanism 3, the stock solution in the discharge mechanism 2 falls into the charging part of the discharge mechanism 2, and wait for a loading After the stock solution is installed in the feeding part, people disconnect the stock solution and turn the discharge mechanism 2, so that the discharge mechanism 2 drives the stock solution to move, and at the same time the stock solution solidifies and forms in the charging part, and then the heating mechanism 3 will carry out the process on the discharge mechanism 2. Heating, thereb...

Embodiment 2

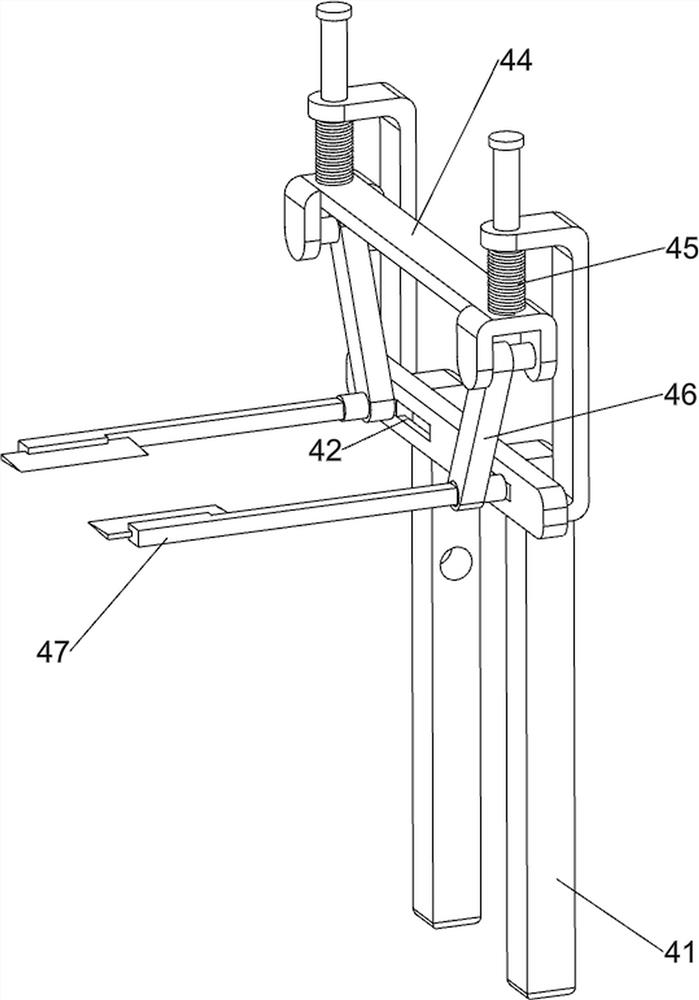

[0042] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, it also includes a cut-off mechanism 4, the cut-off mechanism 4 includes a first cylinder 40, a second pillar 41, a first connection block 43, a first slide block 44, a first spring 45, a second connection block 46 and a second slide Block 47, the base 1 is provided with a first cylinder 40, the base 1 is provided with a second pillar 41, the second pillar 41 is symmetrically provided with a chute 42, and the second pillar 41 is symmetrically provided with a first connecting block 43, the second pillar 41 is symmetrically provided with a first connecting block 43, A first slide block 44 is slidably connected between a connection block 43, a first spring 45 is arranged between the first slide block 44 and the first connection block 43, and a second spring 45 is arranged symmetrically on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com