Metering device for grain and oil processing

A metering device, grain and oil technology, applied in manufacturing tools, fat oil/fat production, fat production, etc., can solve problems affecting oil taste and color, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

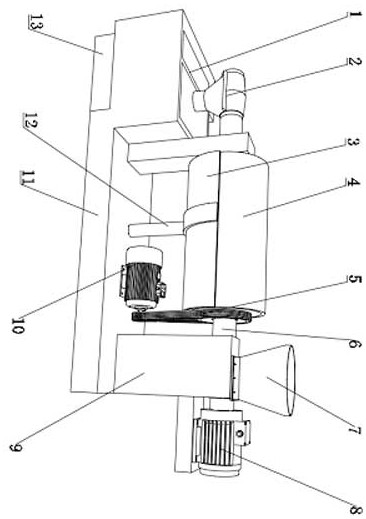

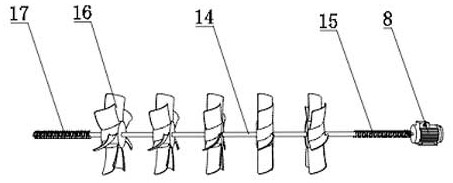

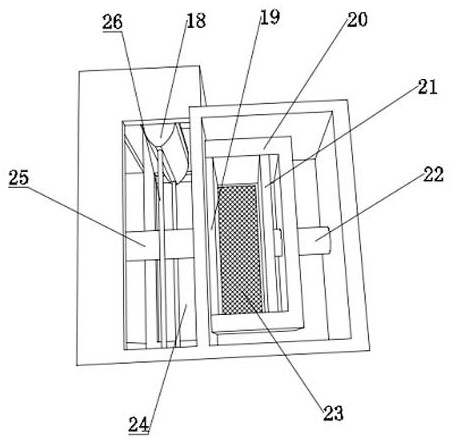

[0034] A metering device for grain and oil processing, such as Figure 1-7 As shown, a base 11 is included, the top of the base 11 is fixedly connected with a fixed column 9, and the number of the fixed columns 9 is two, and one end of the fixed column 9 is fixedly connected with a feeding tube 6, and one end of the feeding tube 6 is fixedly connected There is a shaft sleeve 29, one end of the shaft sleeve 29 is rotatably connected with the roasting tube 4, one end of the feeding tube 6 is fixedly connected with a motor-8, and the top of the feeding tube 6 is fixedly connected with a feed hopper 7, and the motor-8 The output end of the shaft is connected to the rotating shaft 14 through a coupling, and the outer wall of the rotating shaft 14 is fixedly connected with the feeding dragon 15, the stirring blade 16 and the discharging auger 17 respectively, and the stirring blade 16 is arranged on the feeding dragon 15 and the discharging auger 17 Between them, the top of the base...

Embodiment 2

[0038] A metering device for grain and oil processing, such as figure 1 As shown, in order to solve the roasting effect problem; this embodiment makes the following improvements on the basis of Embodiment 1: the inner wall of the roasting tube 4 is fixedly connected with a heating ring, and the heating ring is fixedly connected to one end of the frying material ring 30; By arranging the heating ring, during the roasting process of the grain, the heating plate 3 is changed into a heating ring, which is arranged on the inner wall of the roasting cylinder 4, so that the grain can be roasted better and the roasting effect can be improved.

[0039] When this embodiment is in use, start the motor one 8, and the motor one 8 drives the rotating shaft 14 to rotate, so that the feed dragon 15, the stirring blade 16 and the discharge auger 17 rotate, and the feed dragon 15 continuously and evenly sends the grain into the roasting cylinder 4, the stirring blade 16 stirs the grain, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com