Raw material distribution device with tracking function for construction site and implementation method thereof

A technology for tracking functions and raw materials, applied in signal devices, vehicles for freight, transportation and packaging, etc., can solve the problems of wasted distribution time, affect construction progress, slow distribution speed, etc., to improve work efficiency and improve feeding efficiency. , the effect of easy error correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

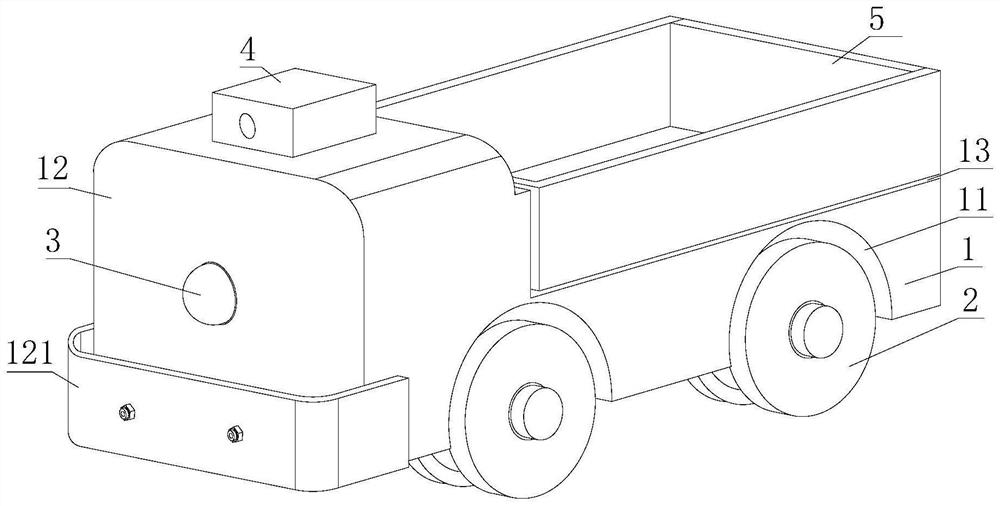

[0035] In order to better demonstrate the implementation process of the raw material distribution device with tracking function for construction sites, this embodiment proposes an implementation method for raw material distribution devices with tracking function for construction sites, including the following steps:

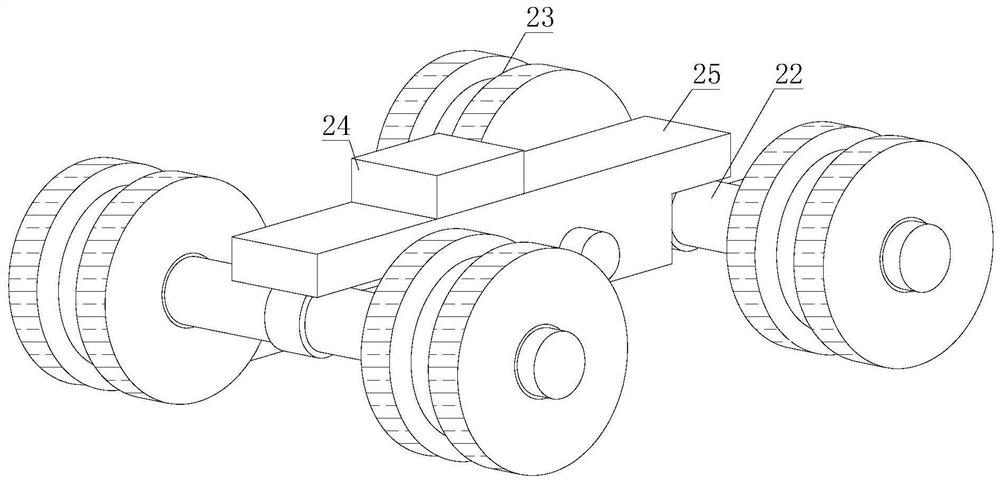

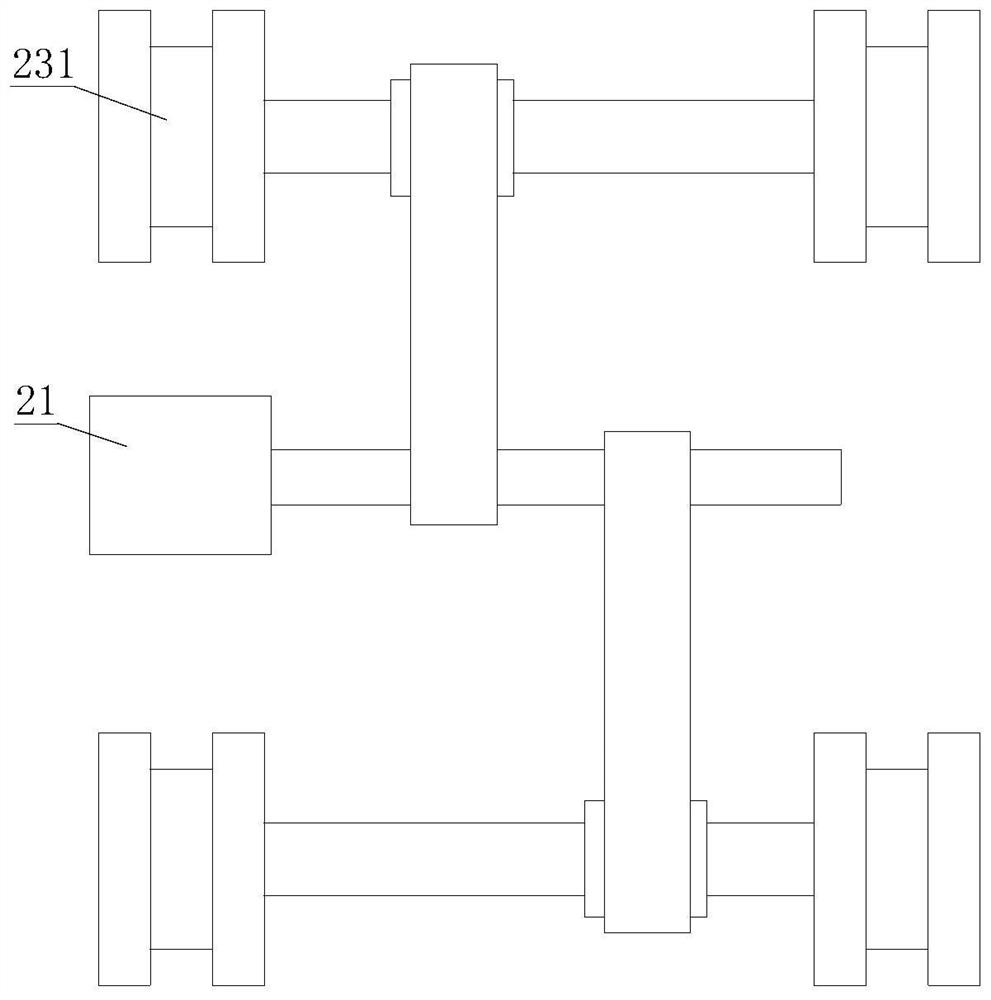

[0036] Step 1: Load the material for construction site into the loading box 5, and drive the roller 23 to rotate through the moving motor 21, thereby driving the entire conveying vehicle body 1 to move;

[0037] Step 2: Manually operate the conveying vehicle body 1 to move to the conveying end point, the camera module 46 takes pictures of the conveying road, stores the video of the route in the storage module 42, and the route simulation module 41 simulates the route and stores the simulated route In the storage module 42, when the route is stored in the storage module 42, the error correction module 45 compares the route simulated in the storage module 42 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com