Aircraft fuel system duct positioning structure and positioning method

A technology of fuel system and positioning structure, which is applied in aircraft assembly, aircraft parts, aircraft power plant, etc. It can solve the problems that affect the production cycle of large aircraft, the difficulty of system conduit assembly, and the limited installation space of the cabin, so as to achieve easy control Clearance and coaxiality, small space occupation, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

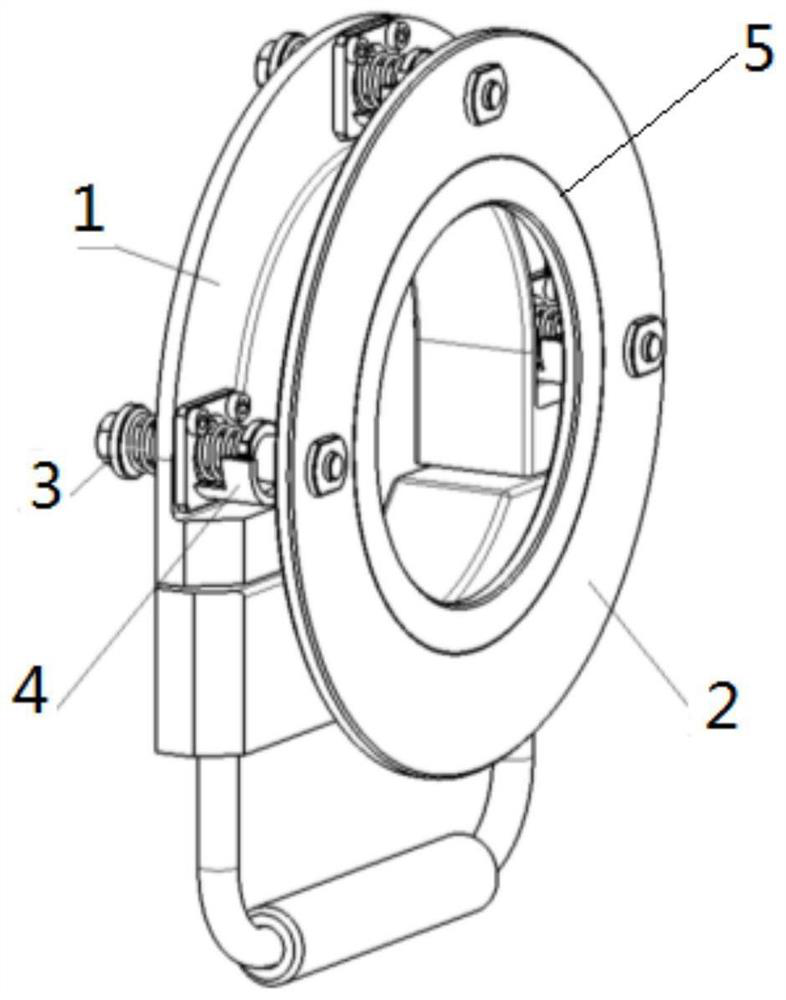

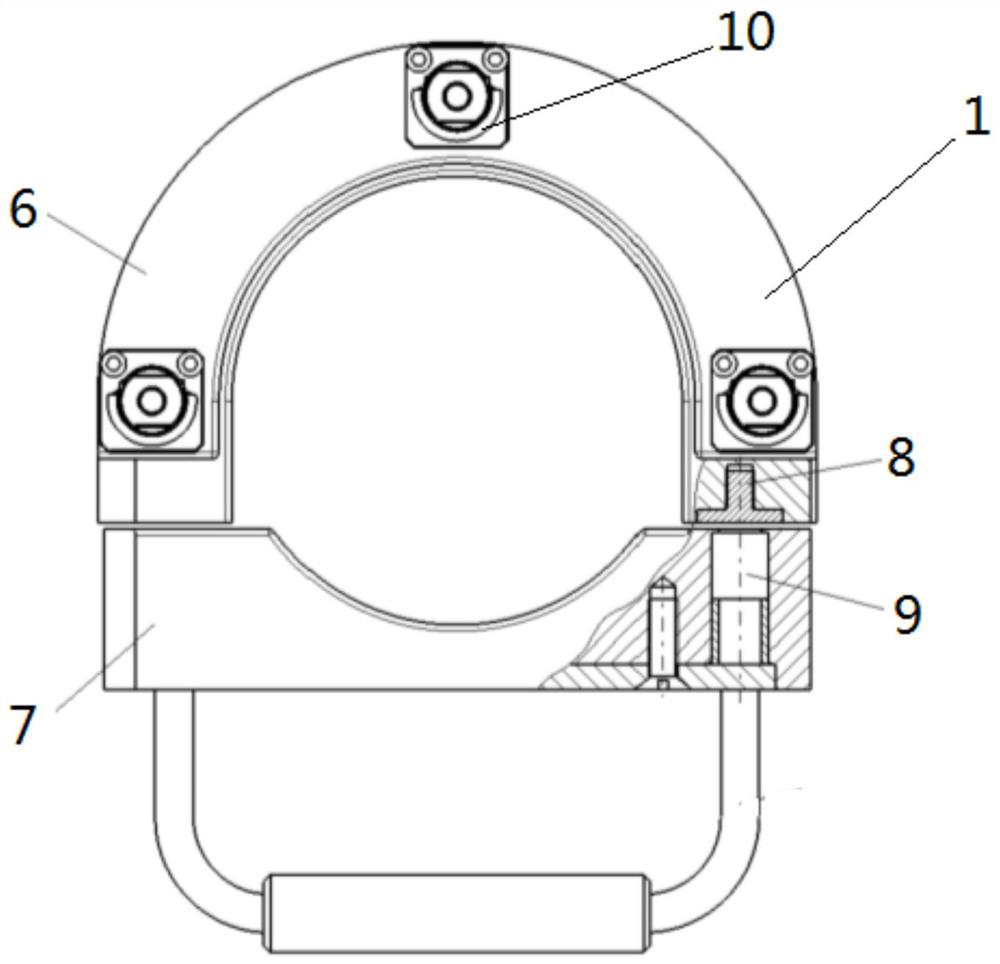

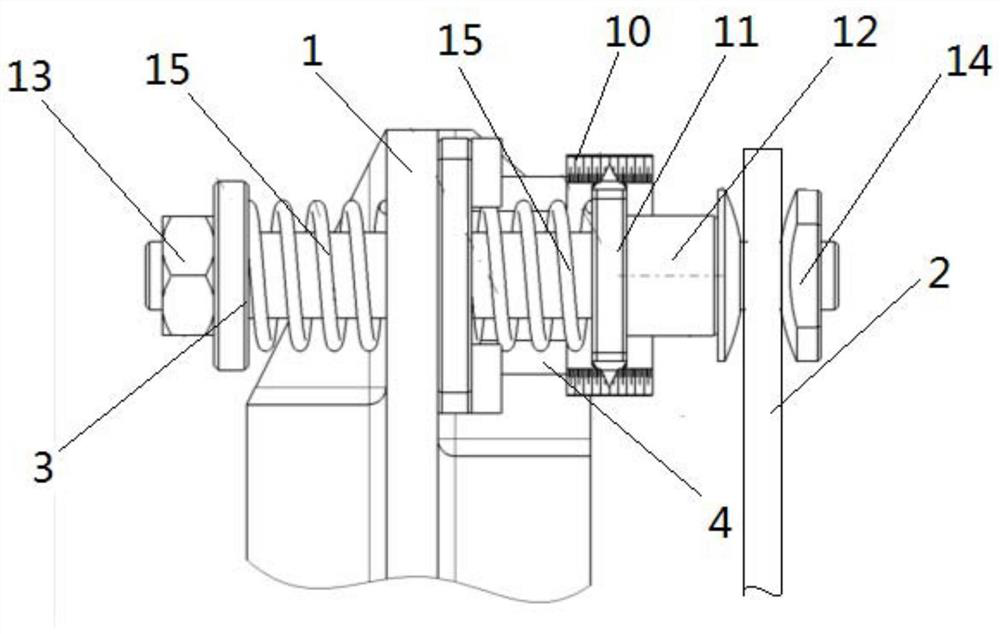

[0016] Referring to the accompanying drawings, the aircraft fuel system conduit positioning structure of the present application includes a clamping band 1, an end face positioning plate 2 and an axial connector 3, and the clamping band 1 includes an upper ring body 6 and a lower ring body 7 , the detachable connection between the upper ring body 6 and the lower ring body 7, in the embodiment, the lower ring body is provided with a handle, the butt surface of the upper ring body 6 and the lower ring body 7 is a magnetic adsorption structure, the lower ring body The docking surface contains a magnet 9, and the docking surface of the upper ring body 7 contains an iron joint 8, and vice versa. In order to connect with the end face positioning plate 2, three connecting holes of the axial connector 3 are provided on the upper ring body 6, and the inner diameter of the clamping clip 1 matches the outer diameter of the conduit of the aircraft fuel system. The end face positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com