Grid frame storage and automatic conveying device

A technology of automatic conveying device and conveying device, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of tight working hours, high labor intensity, tight rest time, etc., and achieves reduced labor intensity and automation. High, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

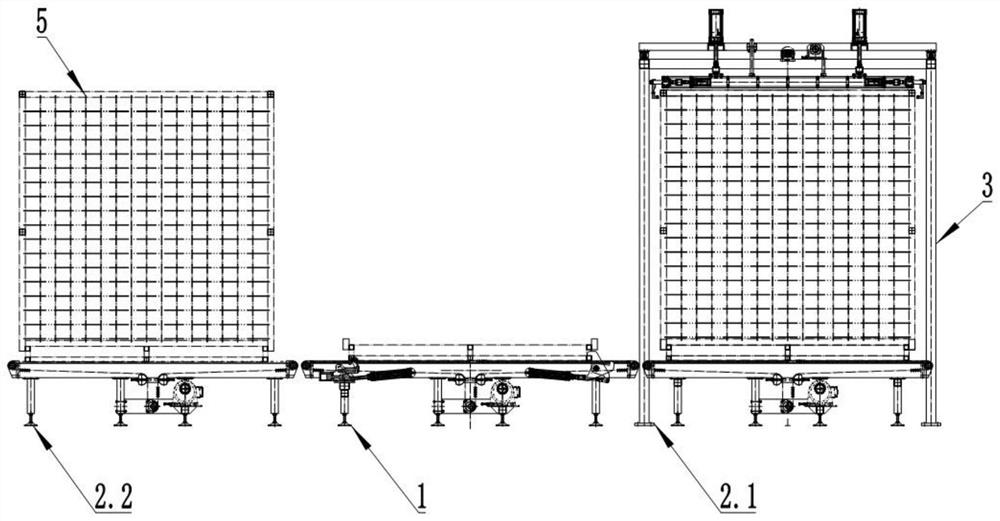

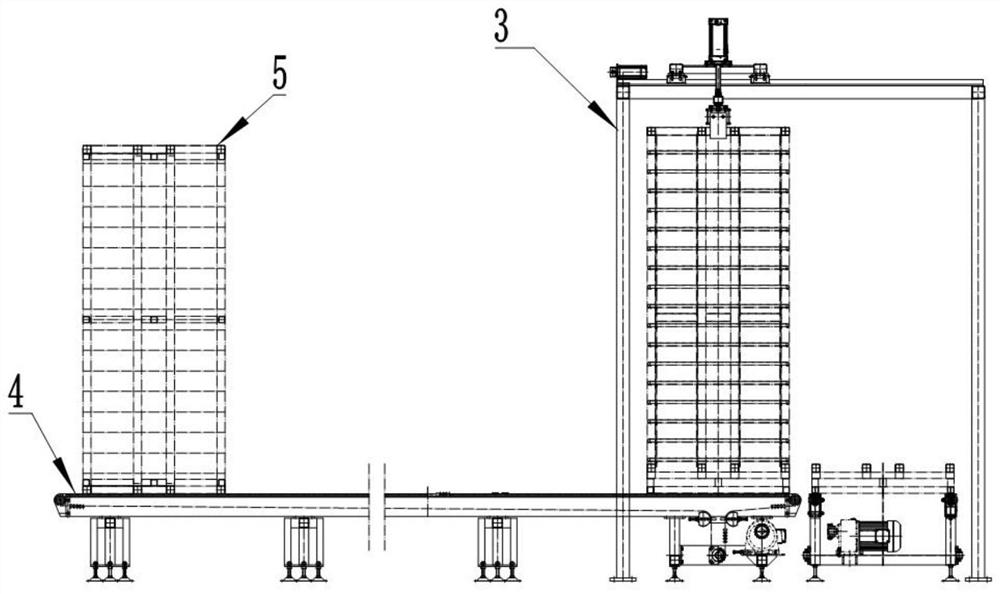

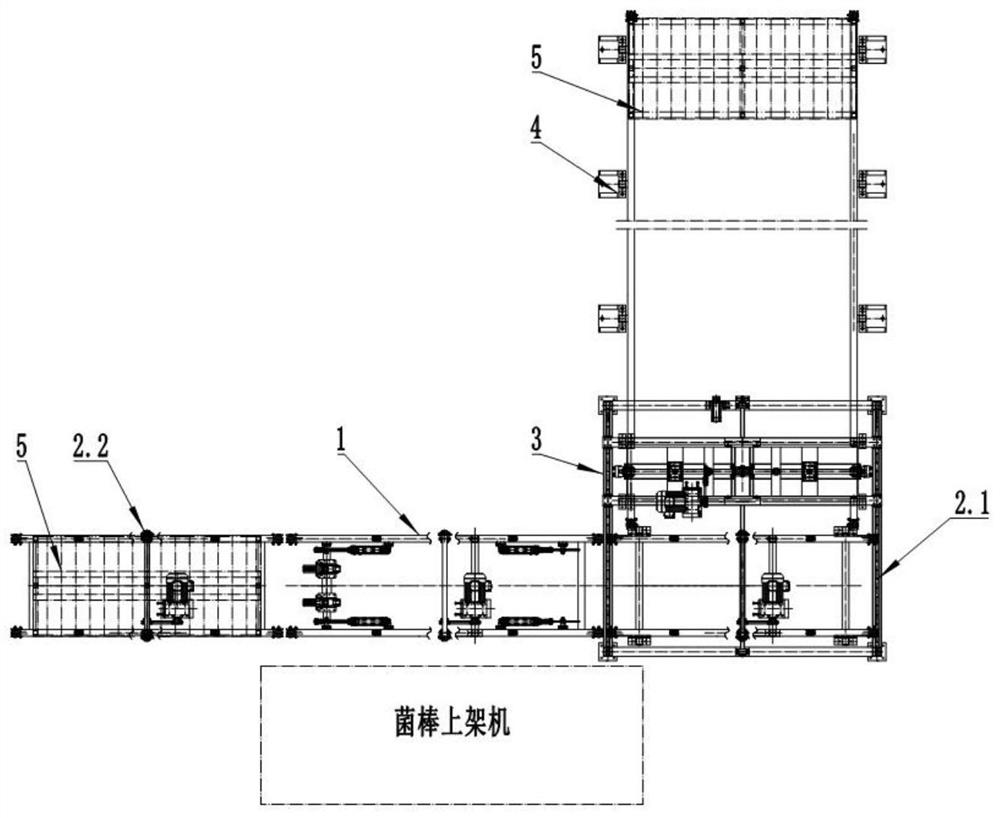

[0031] refer to Figure 1-3 , a device suitable for the automatic factory production of edible fungi, the storage and automatic transportation of grid racks containing bacteria sticks, including working position conveyor 1, grid rack conveyor 2.1, 2.2, empty rack lifting and translation device 3. Empty rack storage and conveying device 4; the grid rack conveyor includes a front grid rack conveyor 2.1 and a rear grid rack conveyor 2.2, which are respectively installed at both ends of the working position conveyor 3, and the empty rack lifting and translation device 3 is also It includes a translation device 3.2 and a grabbing and lifting dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap