Automatic cloth rolling device for non-woven fabric

A technology for automatic cloth rolling and non-woven fabrics, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of reduced production efficiency, no non-woven fabrics, cumbersome operation, etc. Guaranteed smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

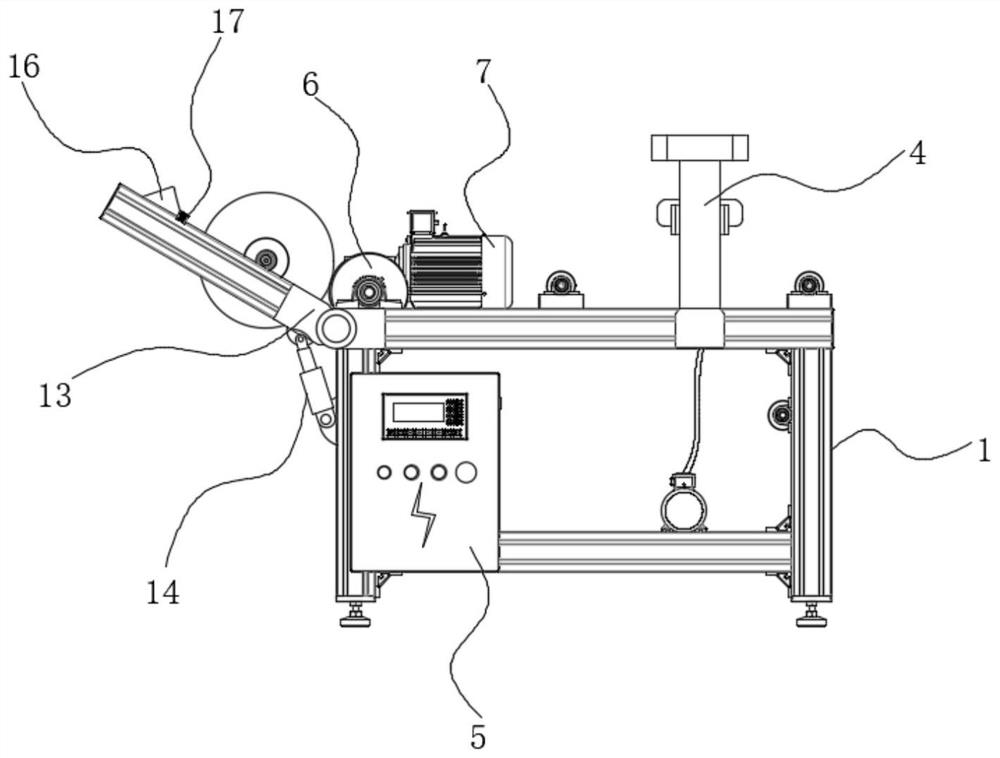

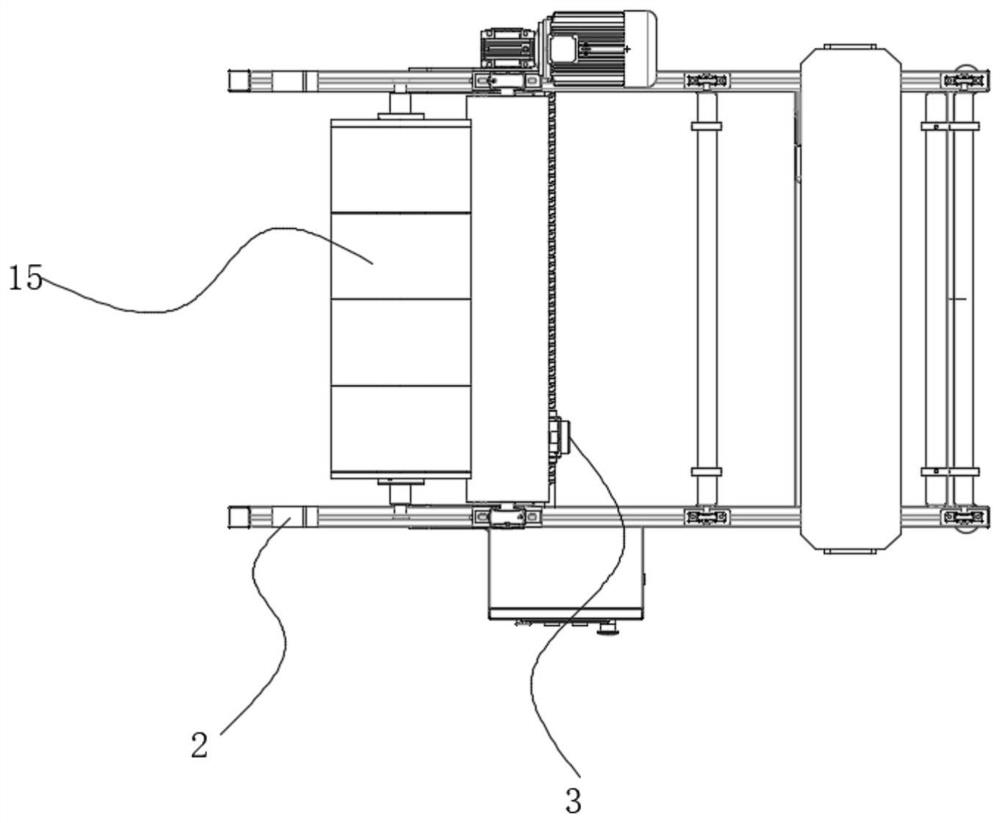

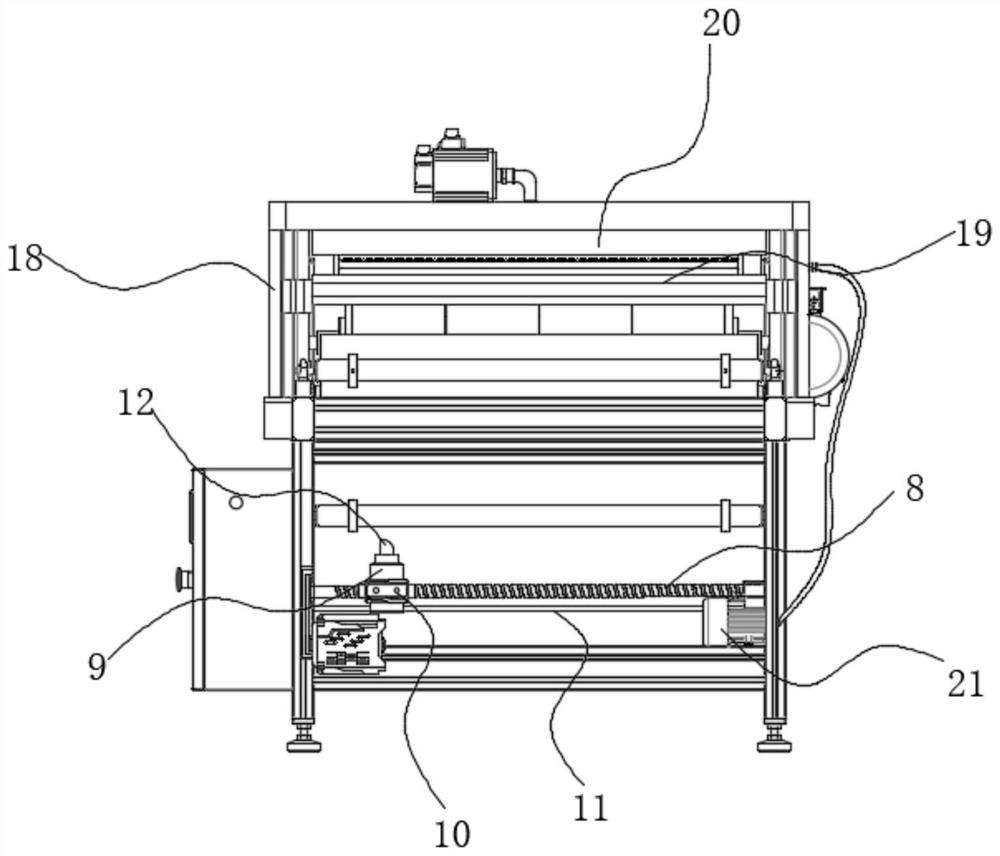

[0039] see figure 1 , in an embodiment of the present invention, an automatic cloth rolling device for non-woven fabrics, which includes a frame 1, an auxiliary pressure assembly 2, a cutting assembly 3 and a limit guide assembly 4, wherein the frame 1 is rotatably provided with A plurality of rotating rollers are used to guide and tension the non-woven fabric. An electric control cabinet 5 is installed on the left side of the frame 1 to regulate the cooperative operation between the components of the device. The upper end of the frame 1 The left side is rotated and provided with a coiling drum 6 for winding non-woven fabrics. The coiling drum 6 is driven by a frequency conversion motor 7 to rotate. The left side of the coiling drum 6 is provided with an auxiliary pressure assembly 2. The pressing assembly 2 is used to compress and flatten the non-woven fabric on the surface of the coil drum 6, so that the non-woven fabric wound up by the coil drum 6 is more compact and smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com