Hole transport material, preparation method thereof and electroluminescent device

A technology of hole transport material and reaction container, which is applied in the field of electroluminescent devices, hole transport materials and their preparation, can solve the problems of unstable hole transport materials and unfavorable mass production, and achieve improved hole injection and transport Performance, improved electron and hole balance, effect of low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

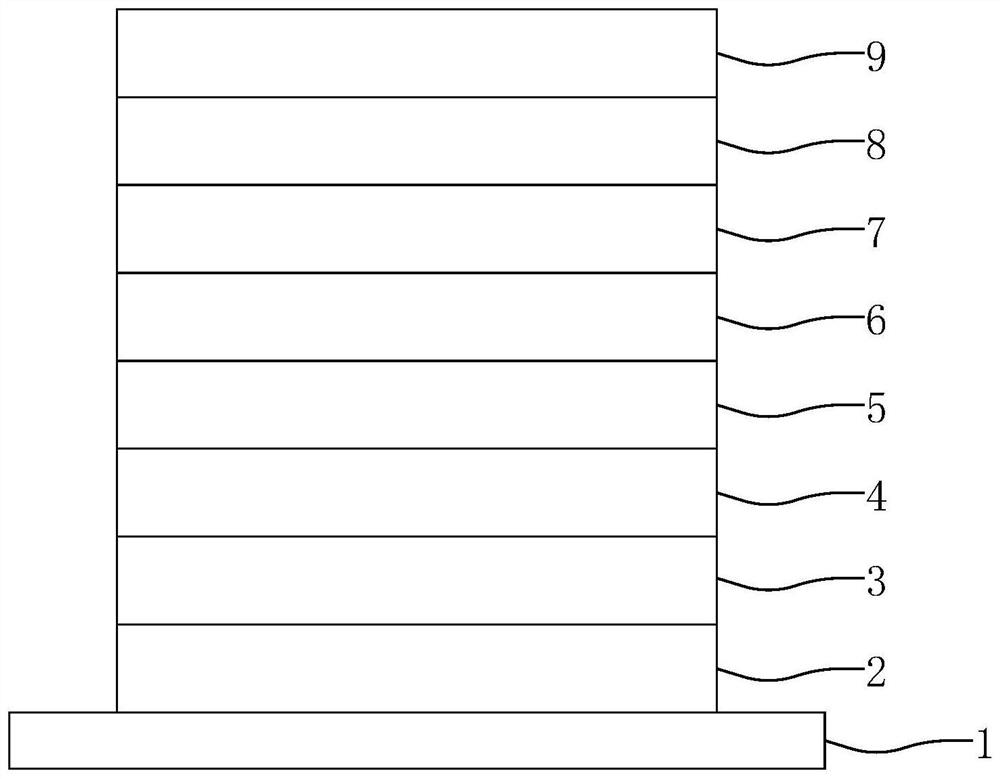

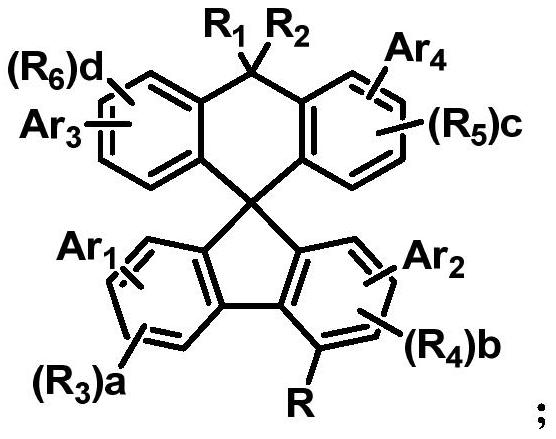

[0050] In the embodiment of the present invention, a hole transporting material is provided, and the main chain in the molecular structure formula of the empty hole transport material is a screw structure, and its molecular structure formula is:

[0051]

[0052] Among them, Ar 1 AR 2 AR 3 AR 4 The at least one aryl or heteroaryl group is included; R is C 1 -C 60 Alkyl, C 1 -C 60 Aryl or C 1 -C 60 At least one of the heteroaryl group; 1 -R 6 Hydrogen, hydrazine, C 1 -C 60 Alkyl, C 1 -C 60 Aryl or C 1 -C 60 At least one of the heteroaryl groups; A, B, C, and D are integers of less than 5.

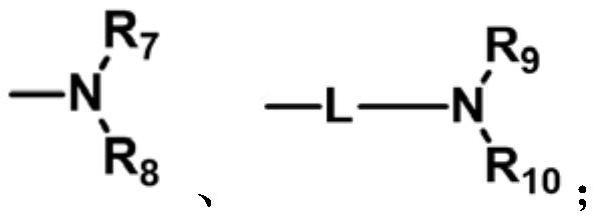

[0053] Specifically, in the embodiment of the present invention, the molecular structure of the AR1 is:

[0054]

[0055] And r 7 R 8 A aryl structure or a heteroaryl structure.

[0056] The R is the structural formula:

[0057]

[0058] The A-D is 0, and R 1 -R 6 All are hydrogen bonds.

[0059] Specifically, the molecular structure formula of the air hole transport material is:

[0060] ...

Embodiment 2

[0087] In the embodiment of the present invention, a hole transporting material is provided, and the main chain in the molecular structure formula of the empty hole transport material is a screw structure, and its molecular structure formula is:

[0088]

[0089] Among them, Ar 1 AR 2 AR 3 AR 4 The at least one aryl or heteroaryl group is included; R is C 1 -C 60 Alkyl, C 1 -C 60 Aryl or C 1 -C 60 At least one of the heteroaryl group; 1 -R 6 Hydrogen, hydrazine, C 1 -C 60 Alkyl, C 1 -C 60 Aryl or C 1 -C 60 At least one of the heteroaryl groups; A, B, C, and D are integers of less than 5.

[0090] Specifically, in the embodiment of the present invention, the molecular structure of the AR1 is:

[0091] And r 7 R 8 A aryl structure or a heteroaryl structure.

[0092] The R is the structural formula:

[0093]

[0094] The A-D is 0, and R 1 -R 6 All are hydrogen bonds.

[0095] Specifically, the molecular structure formula of the air hole transport material is:

[0096]

[0097]...

Embodiment 3

[0123] In the embodiment of the present invention, a hole transporting material is provided, and the main chain in the molecular structure formula of the empty hole transport material is a screw structure, and its molecular structure formula is:

[0124]

[0125] Among them, Ar 1 AR 2 AR 3 AR 4 The at least one aryl or heteroaryl group is included; R is C 1 -C 60 Alkyl, C 1 -C 60 Aryl or C 1 -C 60 At least one of the heteroaryl group; 1 -R 6 Hydrogen, hydrazine, C 1 -C 60 Alkyl, C 1 -C 60 Aryl or C 1 -C 60 At least one of the heteroaryl groups; A, B, C, and D are integers of less than 5.

[0126] Specifically, in the embodiment of the present invention, the molecular structure of the AR1 is:

[0127]

[0128] And r 9 R 10 For a aryl structure or heteroaryl structure, the structure of L is:

[0129]

[0130] The structure of the R is:

[0131]

[0132] The A-D is 0, and R 1 -R 6 All are hydrogen bonds.

[0133] Specifically, the molecular structure formula of the air hole t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com