Construction method of uniaxial stress-strain constitutive model of grouting material special for sleeve

A constitutive model and uniaxial stress technology, applied in the fields of engineering and architecture, can solve problems such as inconsistency, inconsistency in concrete material properties, and no further research, and achieve the effect of avoiding errors and accurate elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the features and advantages of this patent more obvious and easy to understand, the following specific examples are given together with the accompanying drawings and described in detail as follows:

[0044] 1 grouting material raw material

[0045] The raw material of the grouting material in this embodiment is the special high-strength grouting material for sleeves produced by Beijing Sida Jianmao Technology Development Co., Ltd., and it is prepared according to the water consumption required by the product specification. Its basic properties are shown in Table 1.

[0046] Table 1 Grout material properties

[0047]

[0048] 2 Experimental design

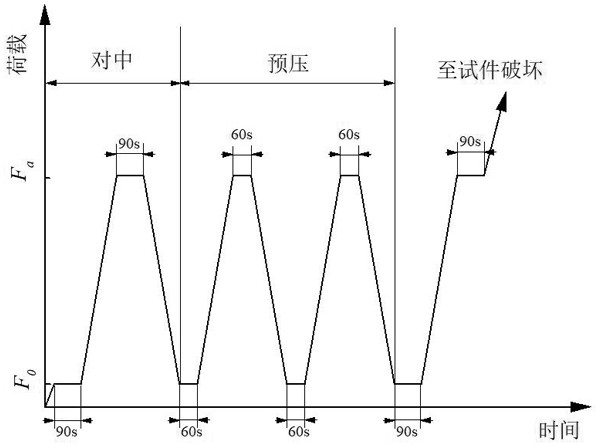

[0049] The test design of this embodiment uses 24 cube test blocks with a size of 70.7mm×70.7mm×70.7mm, 6 cube test blocks with a size of 100mm×100mm×100mm and 6 prisms with a size of 100mm×100mm×300mm test block. The specific information is shown in Table 2. The specimens were demoulded 1 day after f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com