Overturning positioning structure for semiconductor insulating sheath pressing device

A technology of insulating sheath and pressing device, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of inconvenient pressing block positioning, single use mode, and inconvenient turning device, so as to shorten the molding time and design Reasonable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

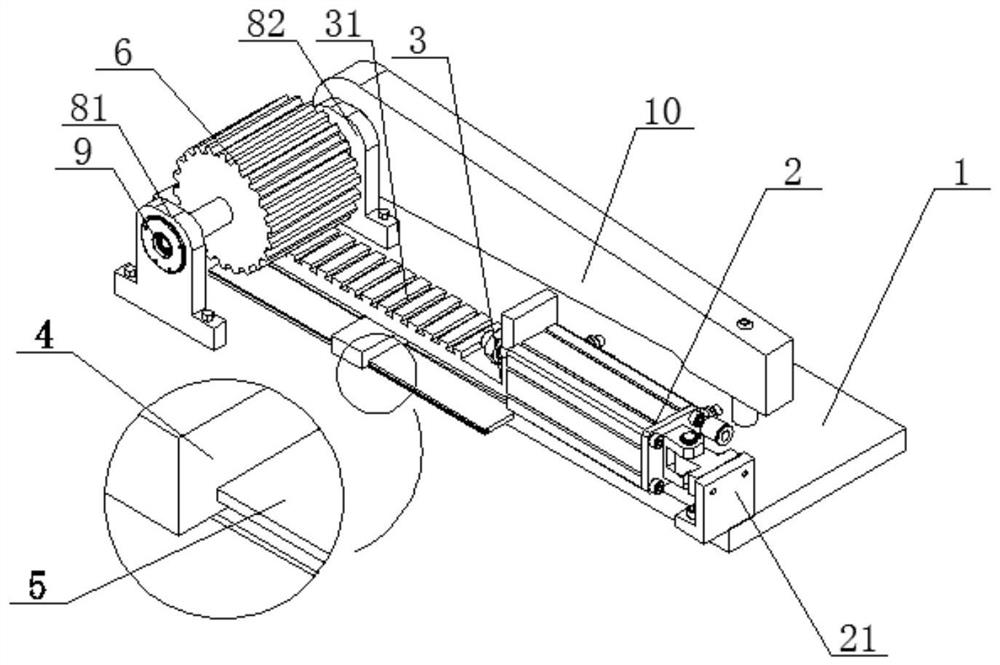

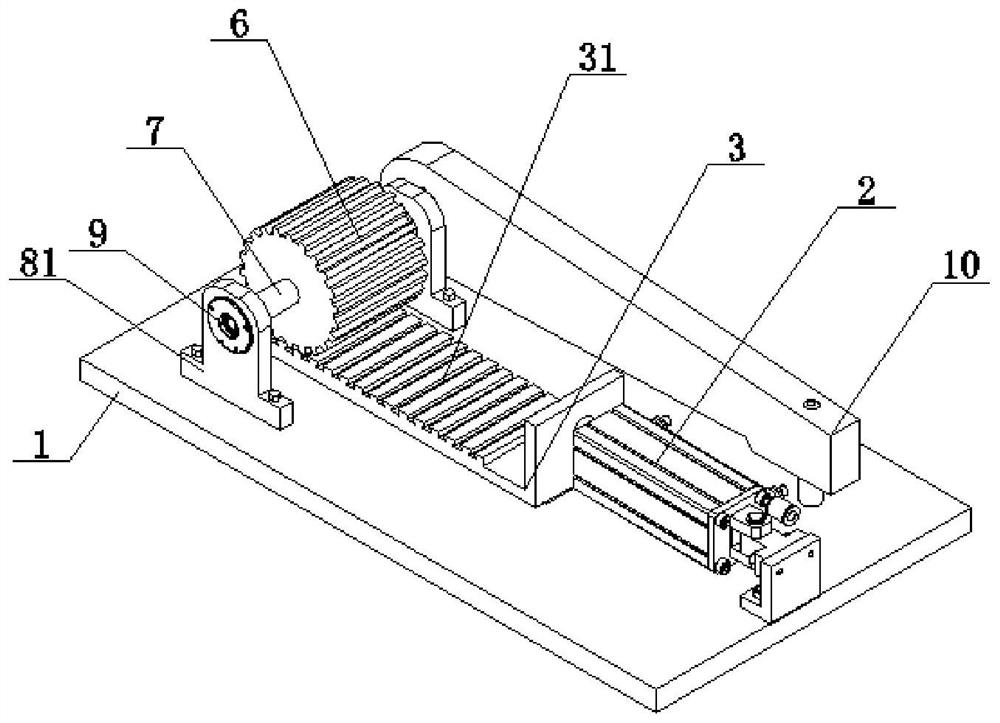

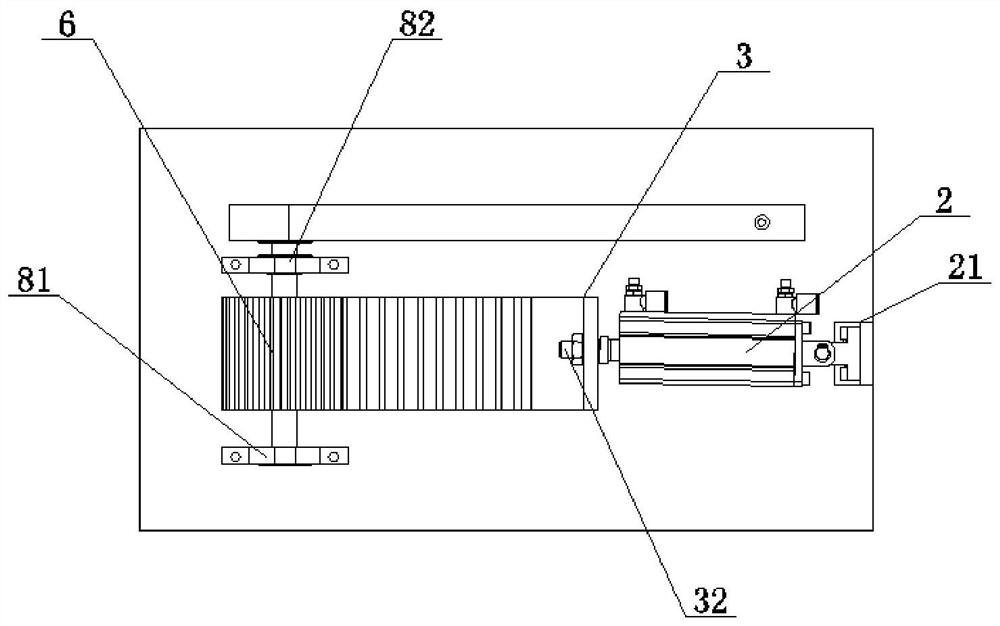

[0023] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Figure 6 According to the present invention, it provides a technical solution: a flip position structure of a semiconductor insulating sheathed press, including a fixed base 1, a hydraulic cylinder 2 disposed at one end of the fixed base 1 for fixing the hydraulic cylinder 2 The connecting shaft 33 connected to the telescopic axis of the hydraulic cylinder 2 is disposed at the movable plate 3 connected to the connecting shaft 33, and the sliding seat 4 at the lower end of the moving plate 3 is disposed, and the slide rail 5 in cooperation with the sliding seat 4, uniform The rack 31 provided on the end surface of the moving board 3, the gear 6, which is engaged with the rack 31, the rotating shaft 7 connected to the gear 6, for the first support seat 81 and the second support 82 for supporting the rotary shaft 7. The block 10 connected to one end of the rotating shaft 7 is disposed on the press ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com