Glass fiber product raw material crushing device

A raw material crushing and glass fiber technology, which is applied in the direction of layered products, synthetic resin layered products, and sound-generating devices, can solve problems such as environmental pollution, large amounts of dust, and health effects on operators, and achieve pollution reduction, pollution prevention, Guaranteed the effect of good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

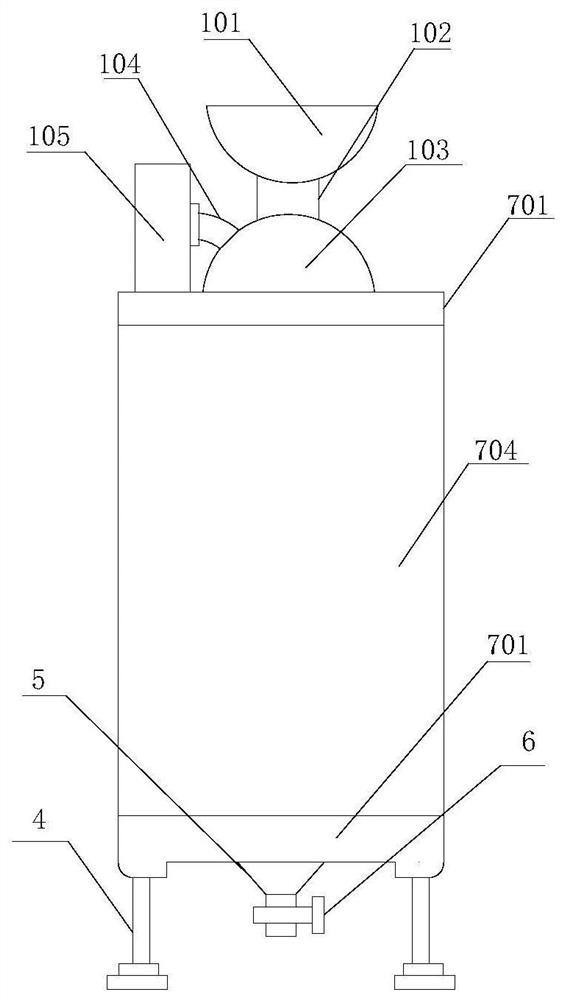

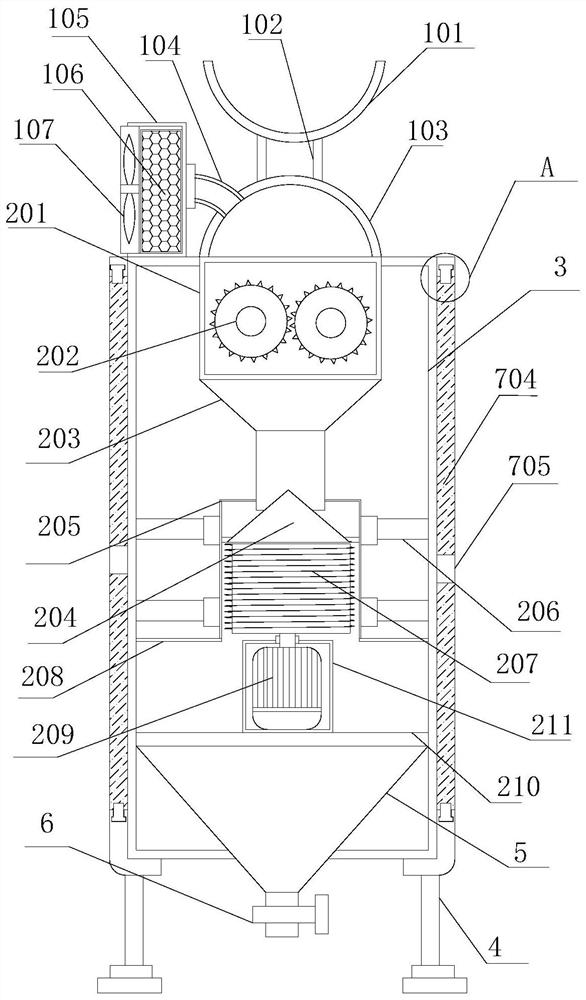

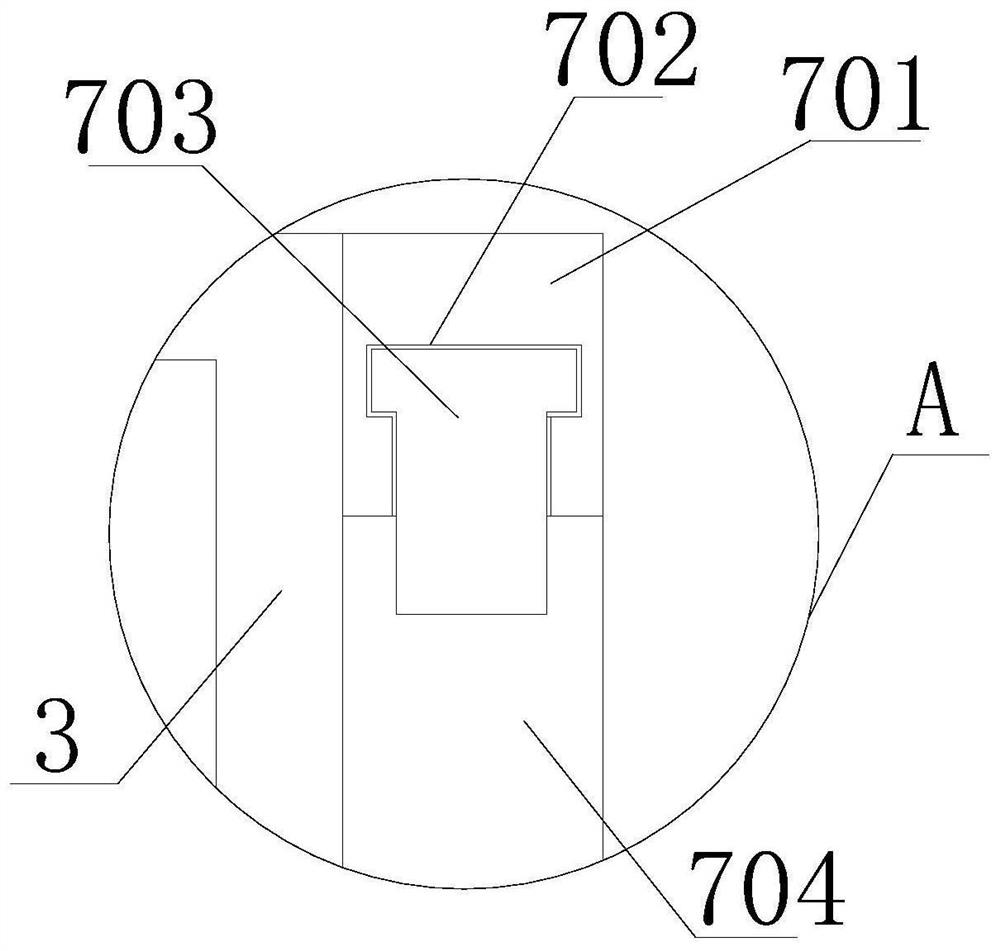

[0025] Such as Figure 1-6As shown, the present invention provides a technical solution: a raw material crushing device for glass fiber products, including a feeding mechanism 1. Dust-removing cloth bag 106, exhaust fan 107, the bottom of feed inlet 101 is fixedly connected with feed pipe 102, the bottom of feed pipe 102 is fixedly connected with dust collection cover 103, feed inlet 101 and dust collection cover 103 are hemispherical settings, And feed inlet 101 and dust collection cover 103 are arranged symmetrically up and down, and the side opening that dust collection cover 103 and feed inlet 101 are far away from each other is arranged, and the left side of dust collection cover 103 tops is fixedly connected with conduit 104, and conduit 104 is away from dust collection cover 103 One side is fixedly connected with the dust box 105, the dust bag 106 is arranged in the inside of the dust box 105, the exhaust fan 107 is fixedly installed on the left side of the dust box 105...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com