Welding tool clamp for large chemical container tank

A tooling fixture, container tank technology, applied in welding equipment, manufacturing tools, metal processing and other directions, can solve the problems affecting the scope of application, can not meet the needs of different diameters of containers, tanks, supports, etc., to improve the scope of use, improve the scope of application , The effect of convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

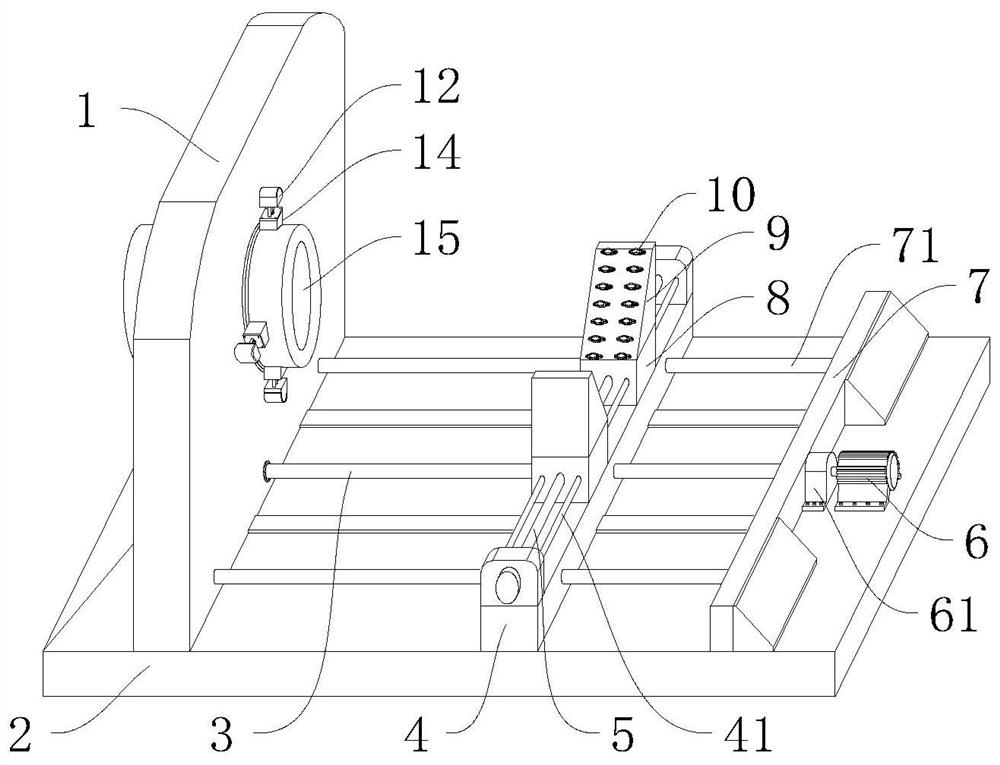

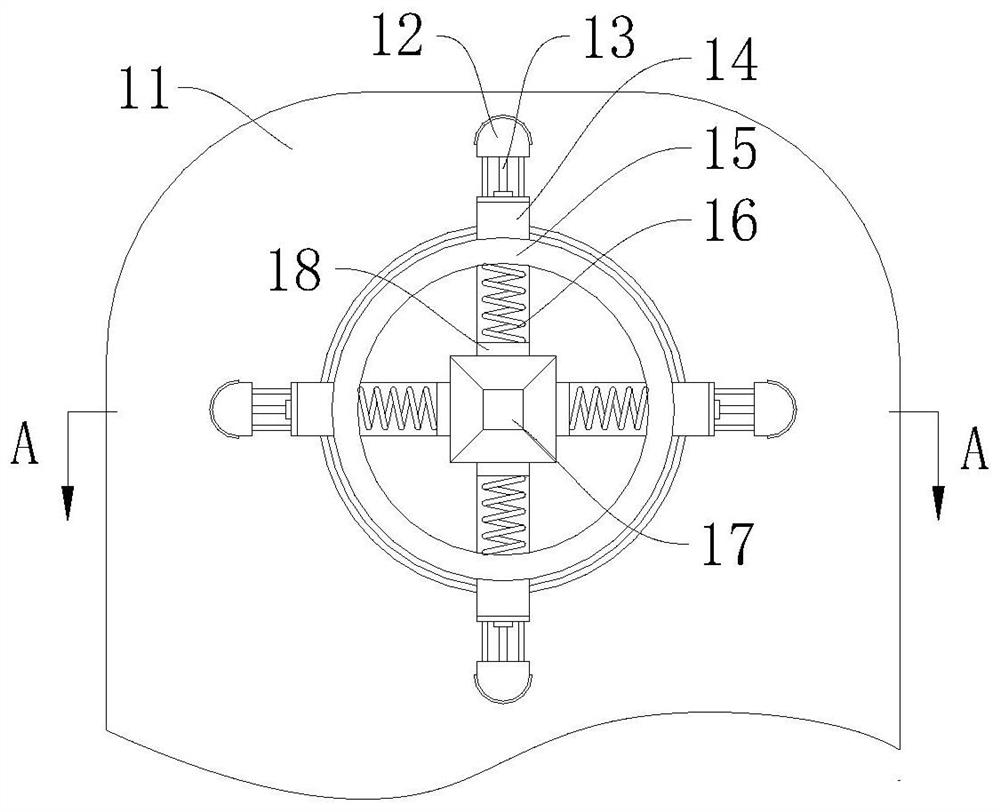

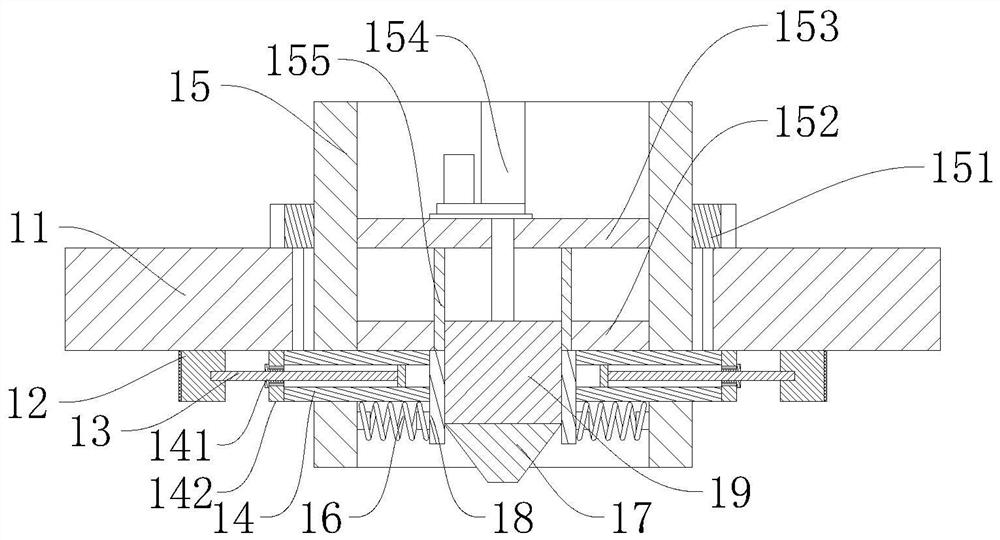

[0025] see Figure 1-Figure 5 , the present invention provides a technical solution: a large-scale chemical container tank welding fixture, including a clamping mechanism 1, a working base plate 2, a screw 3, a moving bar 4, a two-way screw 5, a positioning motor 6, a fixed Seat 7, nut seat 8, wedge-shaped support block 9 and bull's-eye 10, the upper end on the left side of the working base plate 2 is fixedly connected to the clamping mechanism 1, the upper end on the right side of the working base plate 2 is fixed seat 7, between the fixed seat 7 and the clamping mechanism 1 The middle position rotates and connects the horizontally arranged screw rod 3, the ring end of the screw rod 3 is connected to the moving bar 4 through a ball nut pair, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com