Machining method for vehicle support

A processing method and support technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low intelligence in welding monitoring and low welding efficiency, and achieve high automation, low welding error rate, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

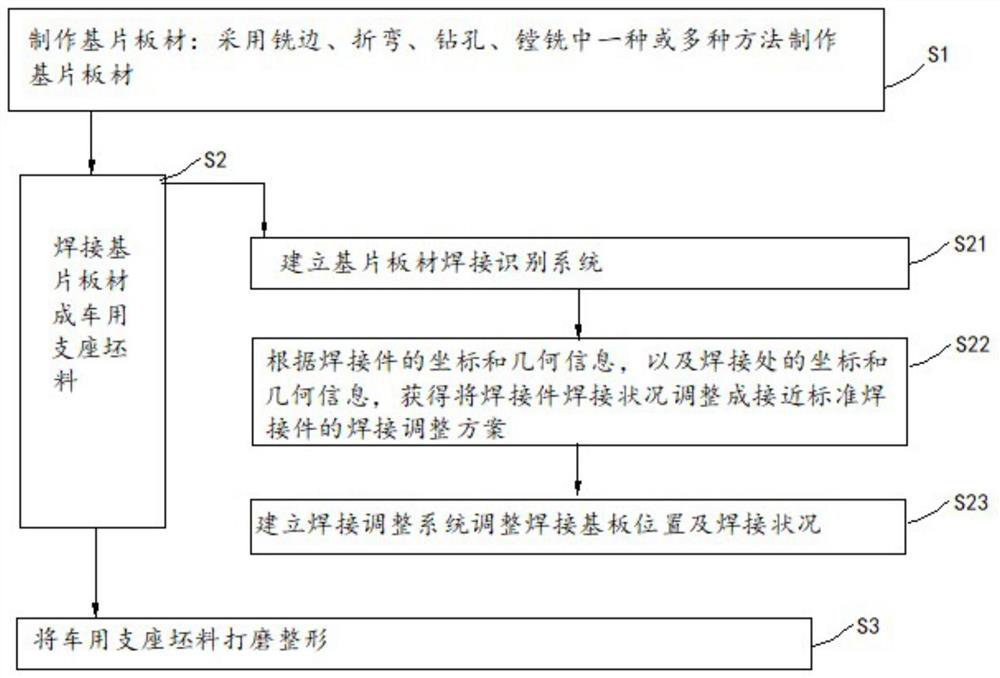

[0024] Aiming at the existing problems, the present invention provides a method for processing a vehicle support, such as figure 1 shown, including the following steps:

[0025] Step S1, making the base plate: using one or more methods of edge milling, bending, drilling, and boring and milling to make the base plate;

[0026] Step S2, welding the substrate plate to form a vehicle support blank;

[0027] Step S3, grinding and shaping the vehicle support blank.

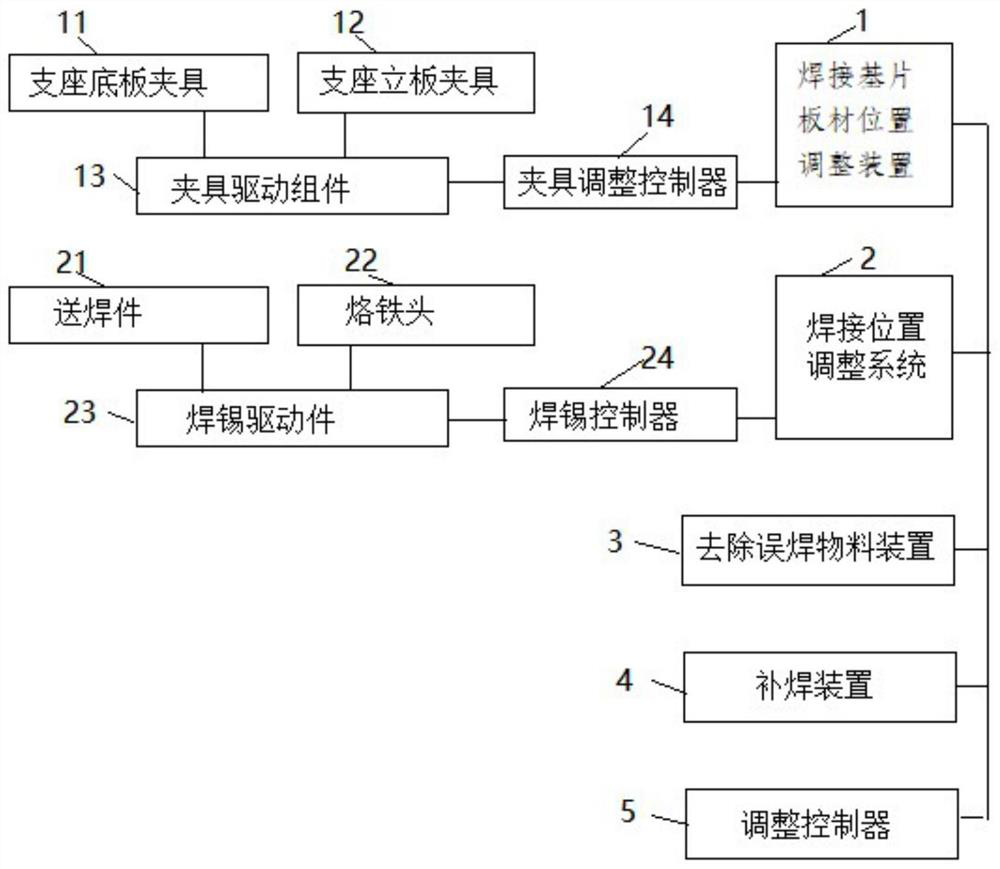

[0028] The step S2 specifically includes: monitoring the position of the substrate plate, the welding position and the size of the weld seam through the substrate plate welding identification system, whether there are missing welds, wrong welds, and whether there are weld defects, and adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com