A permanent magnet electric drum for mine and its assembly method

A technology of electric drum and assembly method, which is applied in the direction of transportation and packaging, conveyors, etc., to achieve the effect of free adjustment and free combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

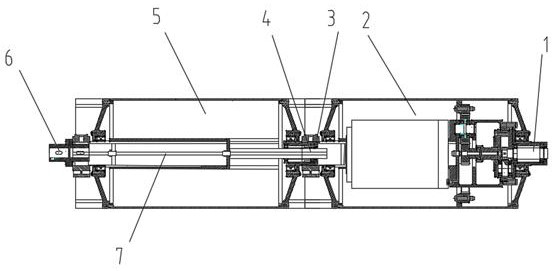

[0045] Embodiment one:

Embodiment 2

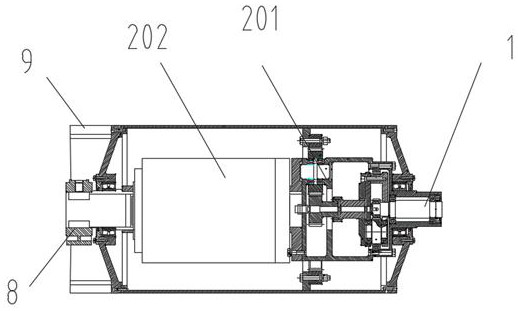

[0047] Embodiment two:

Embodiment 3

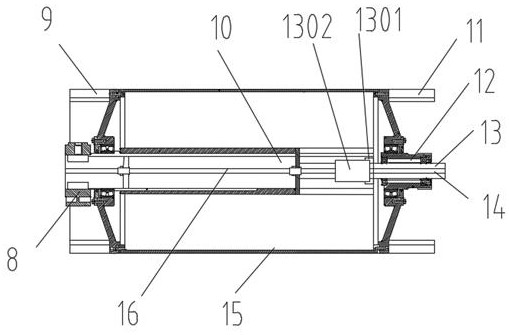

[0049] Embodiment three:

[0050] On the basis of Embodiment 2, in the magnetic field generating device 802, the permanent magnet and the magnetic base are replaced by coils. The pre-assembled wire conduit 16 is inserted into the mandrel 10 to form the assembled wire conduit 7. When the coil is charged, the magneto-rheological locking sleeve 801 can be changed into a quasi-fixed shape to realize the locking of the extension tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com