Filling medium for permeable reactive wall and preparation method of filling medium

A technology for infiltrating reaction walls and filling media, applied in chemical instruments and methods, other chemical processes, water treatment parameter control, etc., can solve the problem that chemical denitrification methods are not suitable for in-situ nitrate removal, physical methods are time-consuming, and treatment costs are high. problem, to achieve the effect of low density, easy transportation, and low secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

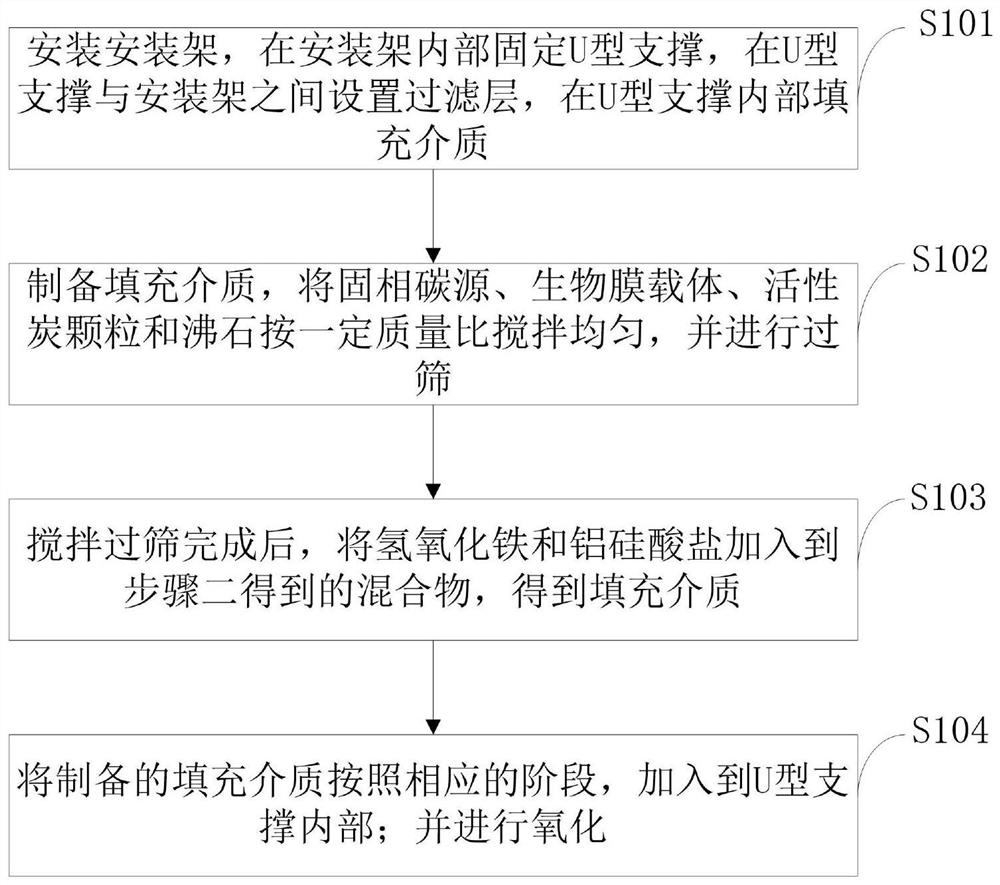

[0053] Aiming at the problems existing in the prior art, the present invention provides a filling medium for a permeable reactive wall and a preparation method thereof. The present invention will be described in detail below with reference to the accompanying drawings.

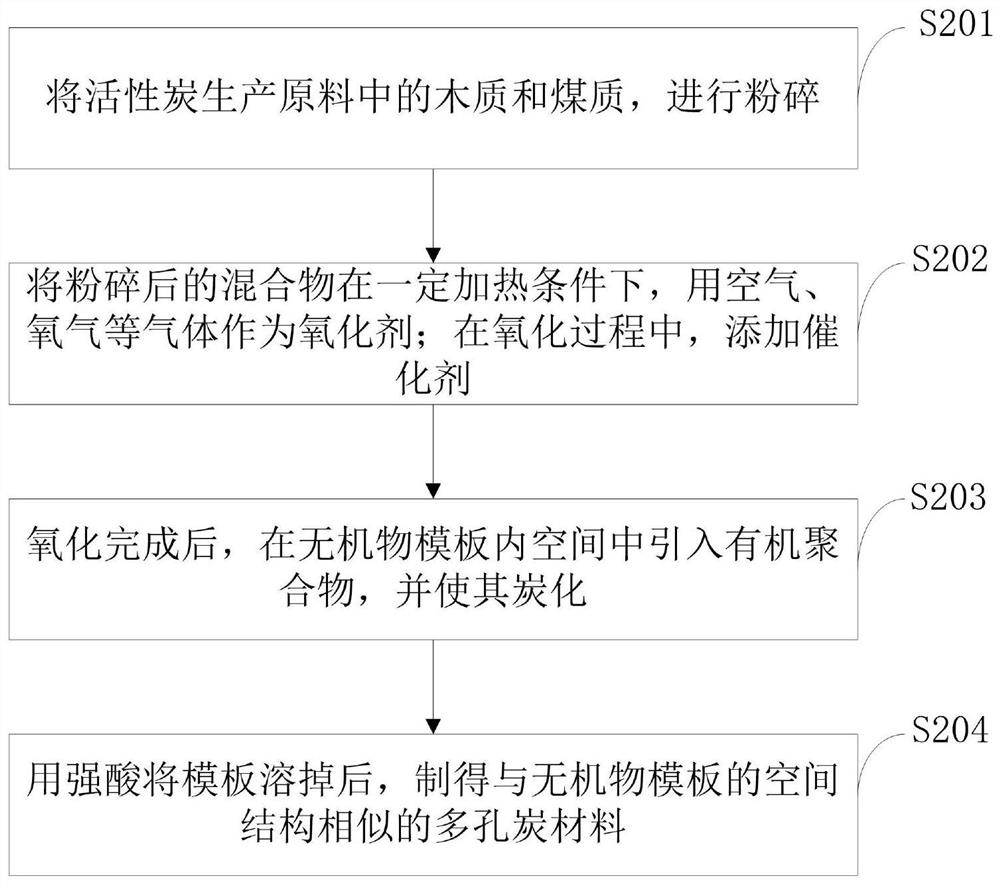

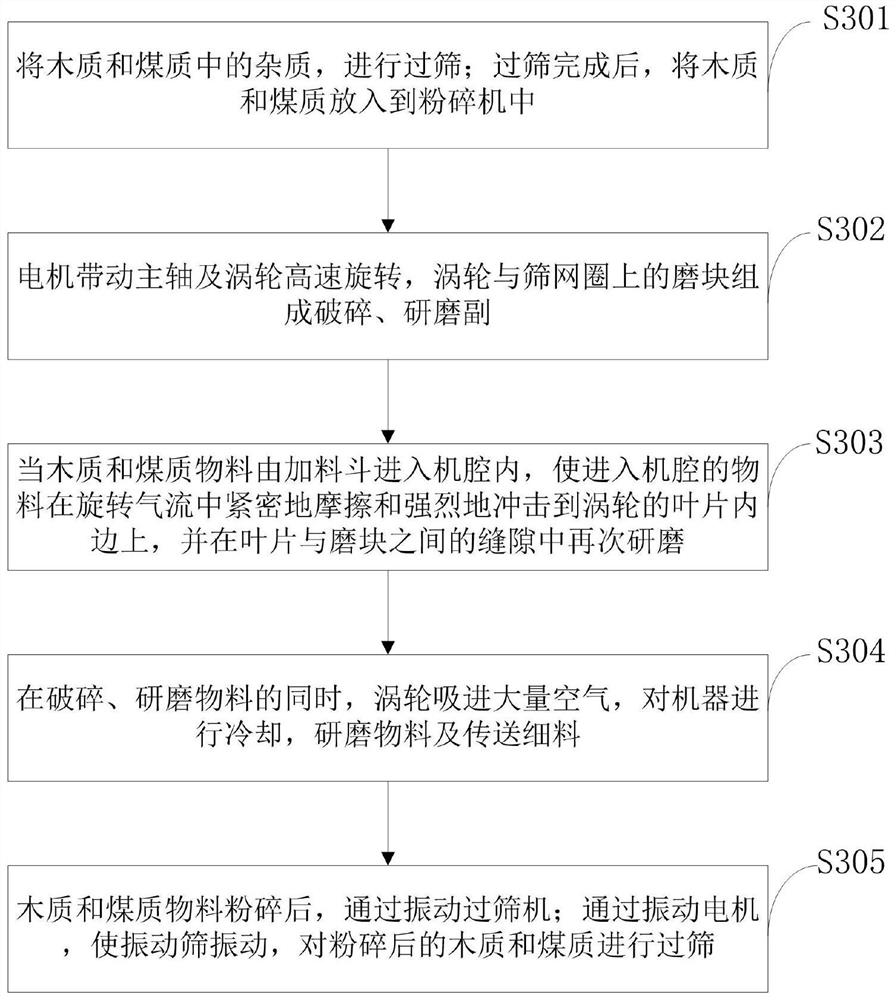

[0054] The filling medium for the permeable reaction wall provided in the embodiment of the present invention is formed by mixing solid-phase carbon source, biofilm carrier, activated carbon particles and zeolite in a mass ratio of 130:2800:75:7; the filling medium for the permeable reaction wall The medium also includes: ferric hydroxide and aluminum silic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap