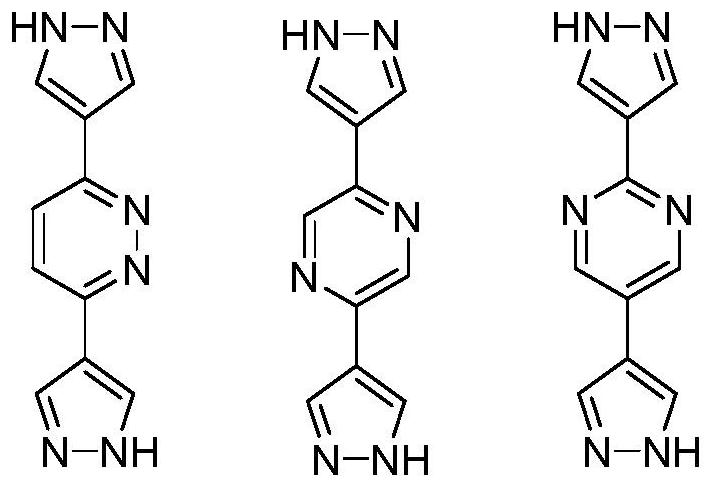

Polynuclear cobalt cluster metal organic framework material based on two-end pyrazole ligands and application

An organic framework and ligand technology, applied in organic chemistry, adsorption purification/separation, etc., can solve the problem of low adsorption selectivity and achieve the effect of good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

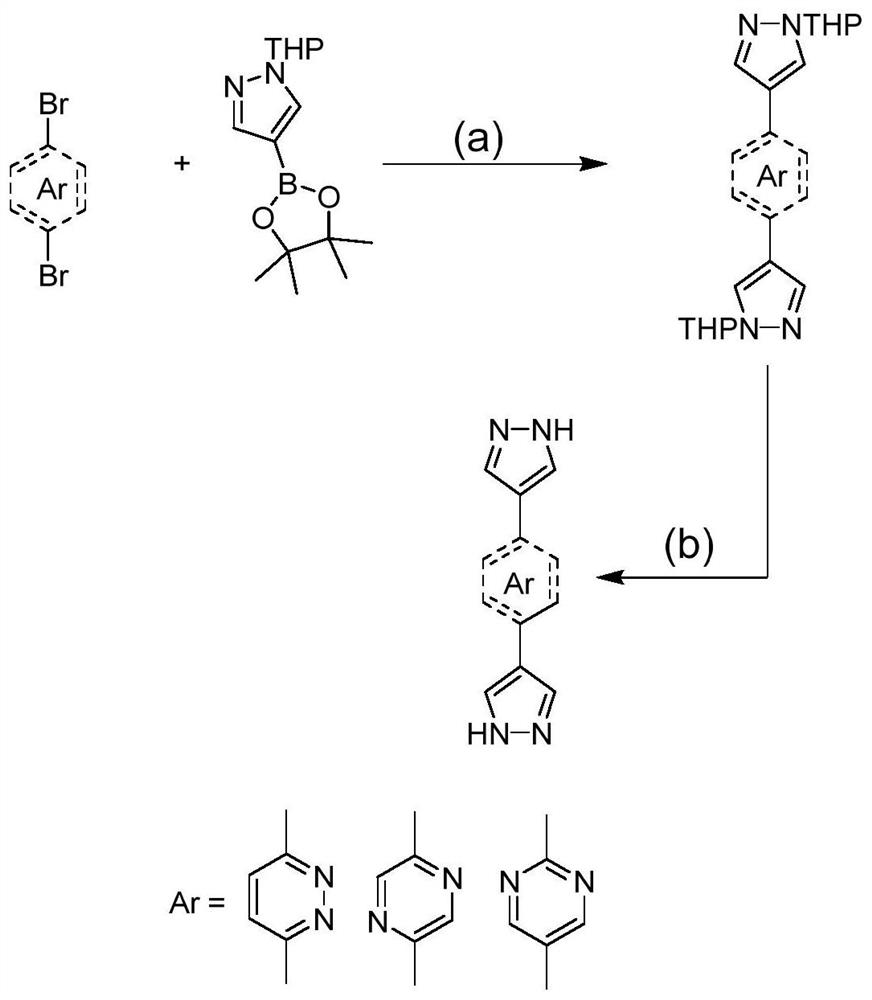

Method used

Image

Examples

Embodiment 1

[0021] Weigh Ligand H 2 BPZ-Pd(0.06mmoL) and Co(NO 3 ) 2 ·6H 2 O (0.12mmoL) was put into a 20mL beaker, and 10mL of DMF solution and 2mL of deionized water were added, and then the beaker was placed into an ultrasonic instrument, and ultrasonicated at room temperature for 5 minutes, and the solution was transferred to a 20mL polytetrafluoroethylene ethylene reactor. After sealing, the reaction kettle was placed in an oven at 110° C. for 24 hours to react. Close the oven after the reaction is over, open the reactor after being cooled to room temperature, filter the product obtained in the reactor to collect solid particles, and the product obtained is washed with DMF, H 2 Washed with O and EtOH (5mL×3), observed under a microscope to obtain yellow octahedral crystals (Co 8 (OH) 4 (OH 2 ) 2 (BPZ-Pd) 6 ), (yield: 43%, based on H 2 BPZ-Pd ligand).

Embodiment 2

[0023] Weigh Ligand H 2 BPZ-Pz(0.06mmoL) and Co(NO 3 ) 2 ·6H 2 O (0.12mmoL) was put into a 20mL beaker, 10mL of DMF solution and 2.5mL of deionized water were added, and then the beaker was placed into an ultrasonic instrument, and ultrasonicated at room temperature for 5 minutes. Vinyl fluoride reactor. After sealing, the reaction kettle was placed in an oven at 105° C. for 48 hours to react. Close the oven after the reaction is over, open the reactor after being cooled to room temperature, filter the product obtained in the reactor to collect solid particles, and the product obtained is washed with DMF, H 2 Washed with O and EtOH (5mL×3), observed under a microscope to obtain yellow octahedral crystals (Co 8 (OH) 4 (OH 2 ) 2 (BPZ-Pz) 6 ), (yield: 49%, based on H 2 BPZ-Pz ligand).

Embodiment 3

[0025] Weigh Ligand H 2 BPZ-Pm(0.06mmoL) and Co(NO 3 ) 2 ·6H 2 O (0.12mmoL) was put into a 20mL beaker, 10mL of DMF solution and 0.5mL of deionized water were added, and then the beaker was put into an ultrasonic instrument, and ultrasonicated at room temperature for 5 minutes. Vinyl fluoride reactor. After sealing, the reaction kettle was placed in an oven at 120° C. for 48 hours to react. Close the oven after the reaction is over, open the reactor after being cooled to room temperature, filter the product obtained in the reactor to collect solid particles, and the product obtained is washed with DMF, H 2 Washed with O and EtOH (5mL×3), observed under a microscope to obtain yellow octahedral crystals (Co 8 (OH) 4 (OH 2 ) 2 (BPZ-Pm) 6 ), (yield: 37%, based on H 2 BPZ-Pm ligand).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com