Concrete-filled steel tube arch bridge transverse support structure, arch bridge and transverse support structure design method

A technology of steel tube concrete and design method, which is applied in the direction of arch bridge, bridge construction, design optimization/simulation, etc. It can solve problems affecting the permeability of pedestrians and traffic, difficulties in high-altitude installation operations, and dense arrangement of cross braces, etc., to improve technical economy Sexuality, shortening the construction period, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

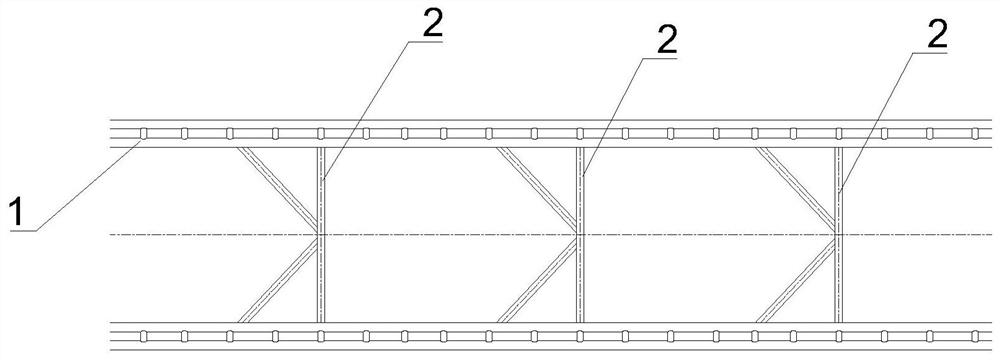

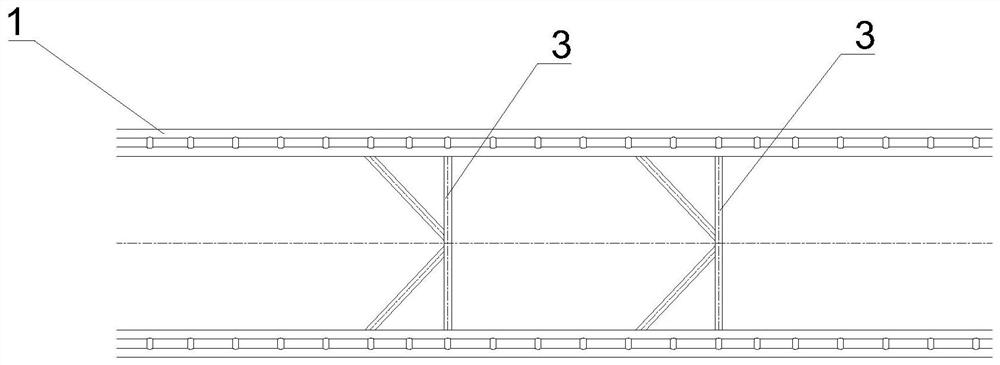

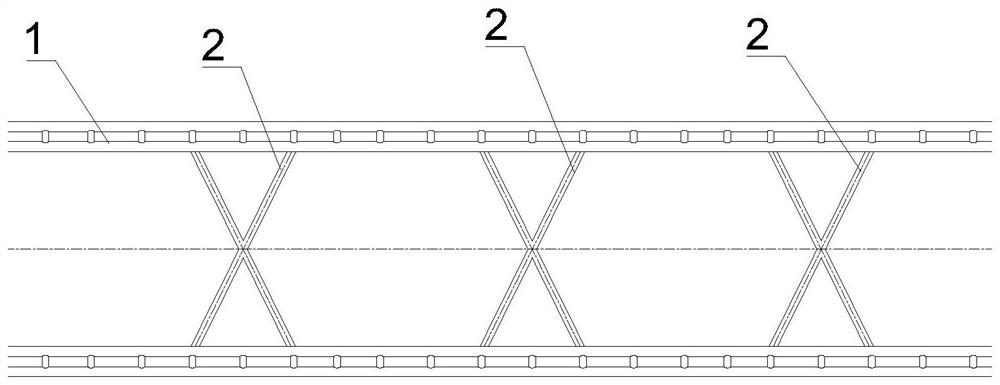

[0053] Such as Figure 1-Figure 5 As shown, this embodiment provides a steel tube concrete arch bridge cross brace structure, including an upper cross brace assembly 2 and a lower cross brace assembly 3;

[0054] The upper cross brace assembly 2 is used to be arranged on the upper plane of the main arch 1, and the lower cross brace assembly 3 is used to be arranged on the lower plane of the main arch 1;

[0055] The number of the upper cross brace assembly 2 and the lower cross brace assembly 3 are different, specifically, the number of the lower cross brace assembly 3 is less than the number of the upper cross brace assembly 2 .

[0056]The upper cross brace assembly 2 and the lower cross brace assembly 3 are misplaced, specifically, the number difference between the upper cross brace assembly 2 and the lower cross brace assembly 3 is 1-3.

[0057] The distance between adjacent upper cross brace assemblies 2 is the first distance, the distance between adjacent lower cross br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com