Coal body heating device and method for promoting gas extraction

A technology of gas extraction and heating device, which is applied to isolation devices, mining fluids, coal gasification and other directions, can solve the problems of heating coal body temperature not higher than 100 ℃, small effective range of microwave heating, and large heating temperature difference, etc. To achieve the effect of improving gas extraction efficiency, convenient transportation and controllable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

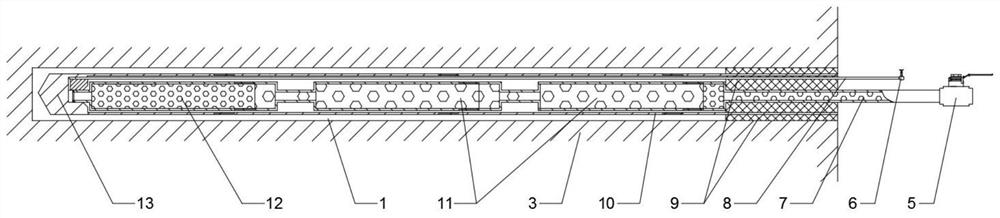

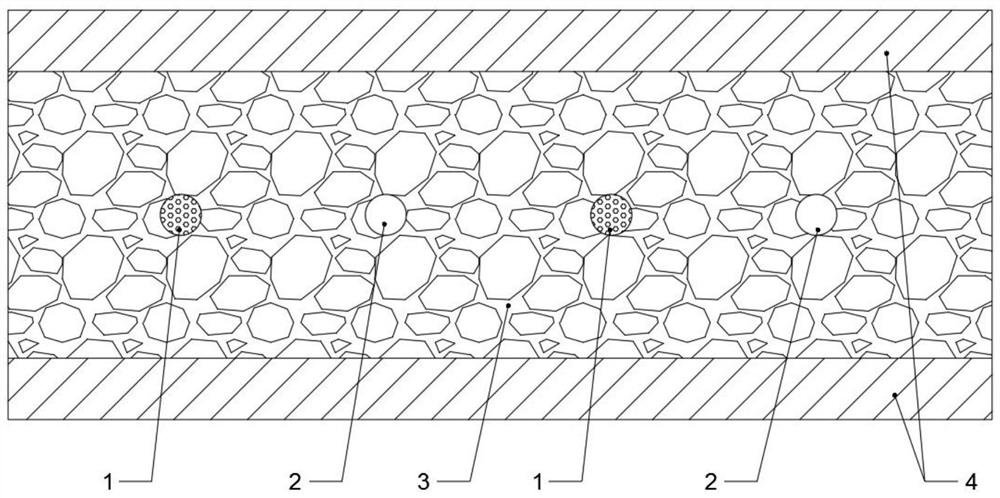

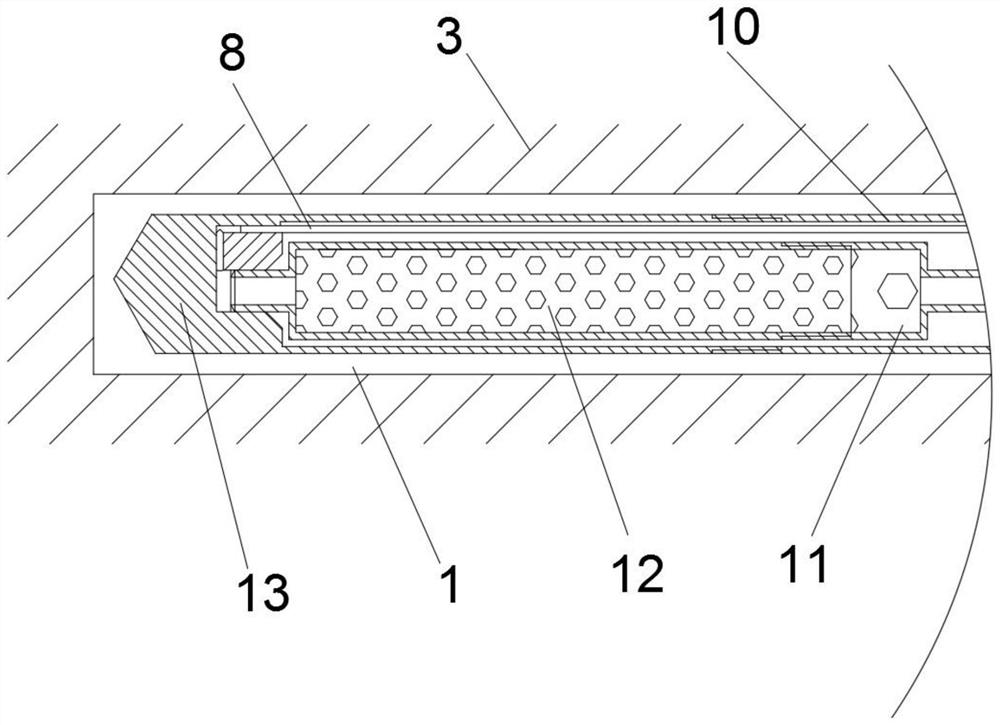

[0034] like Figure 1 to Figure 4 As shown, the present invention provides a coal heating device for promoting gas extraction, which includes a hole-protecting flower tube arranged in a heating hole 1, and the heating hole 1 is opened in a coal seam 3 restricted by a rock formation 4, and the The hole-protecting flower tube is provided with a heating flower tube, and the heating flower tube is filled with a heating medicine bag. The hole-protecting flower tube and the heating flower tube are both unit connection structures. One end of the heating flower tube extends out of the heating hole 1 and passes through the first A valve 5 is connected to the water injection pipe, and the other end of the heating flower pipe is connected to the water return pipe 8. The tail end of the water return pipe 8 extends out of the heating hole 1 and a second valve 6 is set. The water injection pipe, the heating flower pipe and the return water pipe A water flow path is formed between the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com